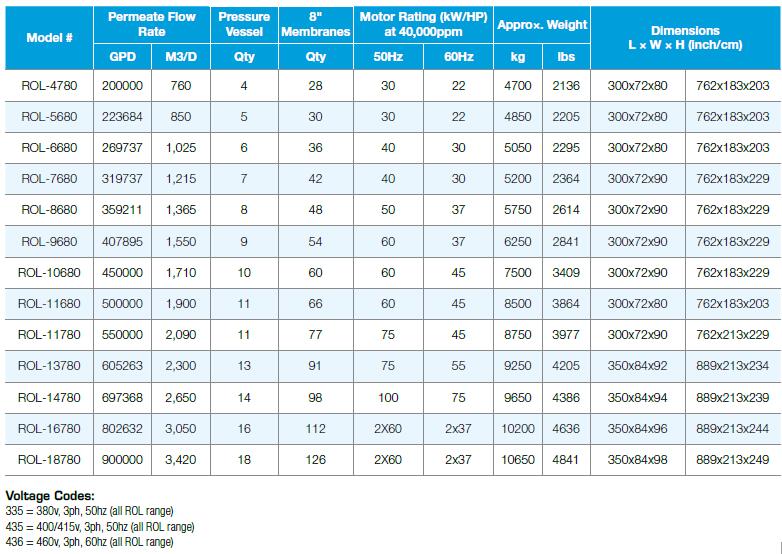

ROL - Industrial Reverse Osmosis System/ 200,000 ~ 900,000 GPD

TWRO SYSTEM, Rogen/ ROL - Industrial Reverse Osmosis System 200,000 ~ 900,000 GPD

Designed to produce low dissolved solids water from tap or well water, these systems use high efficiency reverse osmosis membranes. The product water is used in applications such as semiconductor, boiler feed, pharmaceutical, municipal, water reuse, food processing, bottling, and a wide variety of other applications.

Standard Features | Available Options |

• 8” TFC spiral wound membranes

• Stainless steel multi-stage pump with TEFC motor

• FRP membrane housings

• 5 micron cartridge prefilter

• PLC based control panel

• Programmable time delay and set points

• HMI screen

• Motor starter

• Low pressure switch

• High pressure switch

• Liquid filled pressure gauges

• Permeate conductivity monitor

• Permeate & concentrate flow meters | • Remote monitoring

• Feed water conductivity monitor

• Membrane cleaning skid

• Product tank level switch

• Feed pH monitor with sensor

• Feed ORP monitor with sensor

• Water and hour meters

• Chemical dosing systems

• Media prefiltration systems

• Ozonation and UV sterilization systems

• Water softeners

• Skid mounted with pre or post treatment

• Containerized RO systems |

The Ideal Applications For Brackish Reverse Osmosis Systems Include:

Metal Finishing

Beverage Production and

Bottled Water

Electronics

Pharmaceutical

Mining Industry

Chemical Blending | Safe Drinking Water

Rinse Water

Power Plants

Plating Operations

EDI Pre-treatment

Food and Beverage | Spot Free Product Rinse

Cooling Towers

Laboratory

Boiler Feed Water

Ice Manufacturing

Ion Exchange Pre-treatment |

Operation Conditions:

• Max. feed water temperature: 42°C

• Equipment upgrade for TDS up to 5,000 ppm

• Hydrogen Sulfide must be removed

• Max. Silica tolerance: 25 ppm @ 60% recovery

• Feed water TDS: 0-2,000 ppm

• Operating pressure: 150 to 250 psi | • pH tolerance range: 3-11

• Max. Iron content: 0.05 ppm

• Feed water pressure: 20 to 80 psi

• Hardness over 1 GPG requires water softener

• Turbidity should be removed

• Operate at higher TDS by lowering recovery |