Wuhan Petrochemical’s 120 E-Cell-MK7 units were successfully put into operation

Recently, the EDI system provided by SUEZ-WTS for the Wuhan Petrochemical desalination project in China and South Korea has been debugged and officially put into use. This project uses a total of 120 E-Cell-MK7 units, which is another large-scale E-Cell-MK7 application project of SUEZ-WTS in China.

We sell Suez now Veolia, EDI Stack E-Cell- MK-7

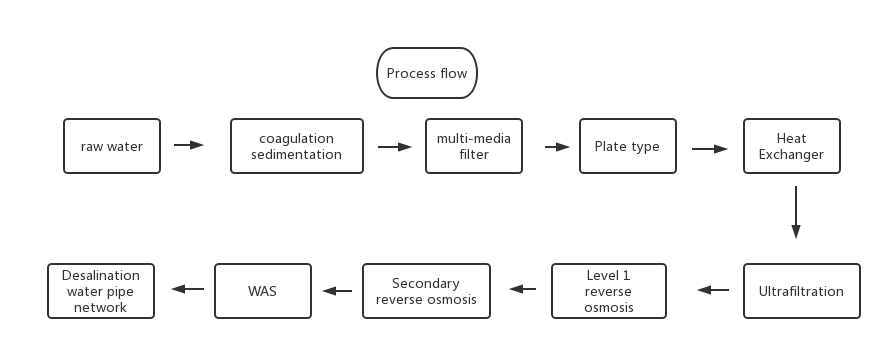

In August 2019, the 700,000 tons/year gas fractionation unit and system supporting project of China-Korea Wuhan Petrochemical was completed by CCCC. SUEZ-WTS provided reverse osmosis membranes for the desalination process for the project.

Based on the stable operating results of the RO system, the user and SUEZ-WTS reached further cooperation this year and decided to connect SUEZ-WTS's EDI water to the desalted water pipe network to produce high-quality industrial process water and boiler feed water, etc., and promote the production of water Reuse and reduce water consumption.

design parameters

The entire system has a total of 4 sets of devices, with a total designed water production capacity of 800m3/h, specifically including the following equipment:

Table 1 EDI and RO system design parameters |

Unit | Model | Number of sets | Quantity | Single set design water production capacity(m³/h) | Recovery rate |

Level 1 RO | AG8040F400FR,34 | 4 | 936 | 190 | 75% |

Level 2 RO | AK-440 | 4 | 744 | 225 | 90% |

Thick water RO | AG8040F400FR,34 | 3 | 270 | 60 | 50% |

EDI | E-Cell-MK7 | 4 | 120 | 200 | 90% |

SUEZ-WTS's patented E-Cell EDI technology has a history of more than 20 years and is currently becoming more and more popular in my country, especially the large-flow EDI module E-Cell-MK7, because of its high degree of automation, stable effluent quality, and environmental economy. The benefits are obvious and it is especially suitable for petrochemical, coal chemical, steel, photovoltaic and other industries with large water production scale. Its advantages are summarized as follows:

Reduce module investment costs. Compared with the previous generation E-Cell-3X module, the traffic volume is increased by 40%

Reduce system supporting investment costs. Taking 500t/h water production as an example, the system supporting costs can be reduced by 20%.

The outlet water quality is excellent, and the outlet water resistance is 10-25% higher than other brands.

Strict quality control, each module is issued with actual test data

We sell Suez now Veolia, EDI Stack E-Cell- MK-7

Operating data

Since the project was put into operation, the water quality and quantity have met the needs of users, the desalination rate is excellent, and the resistivity of EDI produced water has reached 16 MΩ.cm

parameter | First level reverse osmosis | Secondary reverse osmosis | Concentrated water reverse osmosis | EDI |

Inlet water conductivity (μs/cm) | 340 | -- | 1159 | 2.6 |

Product water conductivity (μs/cm) | 4.5 | 1.5 | 16.6 | 0.06 |

Desalination rate(%) | 98.7 | -- | 98.6 | -- |

Recovery rate(%) | 73 | 89 | 50 | 90 |