Containerized SWRO and BWRO System

Against the backdrop of uneven global water distribution and the growing problem of freshwater scarcity, seawater desalination technology has become a key means of supplementing freshwater resources. The FG Water Containerized SWRO and BWRO System (Containerized Seawater/Brackish Water Reverse Osmosis System) launched by FG Water, with its integrated and highly reliable design, provides an efficient solution for freshwater demand in various scenarios.

Centered on reverse osmosis technology—the mainstream technology worldwide—this system is specifically designed for desalinating seawater and brackish water, capable of producing pure freshwater that meets drinking water standards. Its daily production capacity ranges from 60 to 1000 tons (equivalent to 15,000 to 260,000 gallons), which can adapt to diverse water consumption scales, from small communities to large-scale projects.

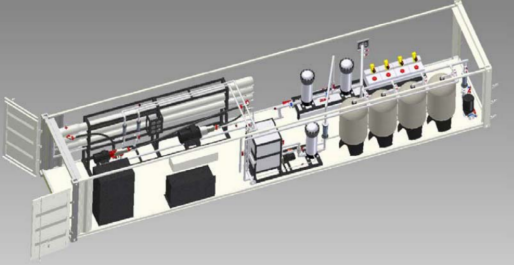

The system adopts a fully integrated container design, integrating four core modules—pretreatment, reverse osmosis (RO), chemical cleaning, and chemical dosing—into a standardized container. The advantages are remarkable:

Reduced on-site construction: No additional workshops or roofs need to be built; only simple on-site connection is required, significantly shortening the installation and commissioning time.

Convenient and flexible transportation: The container structure complies with global transportation standards and can be quickly delivered to destinations by sea or land, making it particularly suitable for remote coastal areas or emergency scenarios.

Selected core components: Key components are all from well-known brands in the water treatment field, such as Danfoss (high-pressure pumps), LG Nano (reverse osmosis membranes), Siemens (PLC), Schneider (control components), etc., ensuring long-term stable operation.

Standardized manufacturing: Designed and produced in strict accordance with international industrial standards such as ASME, ASTM, and IEC, ensuring the safety and compliance of the system.

Seawater Intake: Seawater is pumped by an intake pump. If the water intake point is close and the turbidity of seawater is low, the seawater can be directly sent to the system; if the turbidity is high or the intake point is far, the seawater needs to be temporarily stored in a feed tank first.

Pretreatment and Purification: After being pressurized by the feed pump, the seawater first enters the media filter to remove particulate impurities, and then passes through the cartridge filter (5μm absolute filtration + 1μm nominal filtration) for further purification to prevent clogging of membrane elements.

Reverse Osmosis Desalination: The pretreated seawater is pressurized to 20-70 bar by a high-pressure pump (with frequency conversion function) and sent to the reverse osmosis membrane module. Under pressure, water molecules pass through the membrane to form freshwater, while the high-salinity concentrated water is directly discharged, and finally pure drinking water is obtained.

The system uses standardized containers as carriers, with the common specification being 20ft. The specific dimensions are shown in the following table:

| Container Specification | Length | Width | Height |

|---|

| 40ft (Optional) | 12.1m | 2.44m | 2.89m (9.6ft) |

| 20ft (Commonly Used) | 6.1m | 2.44m | 2.89m (9.6ft) |

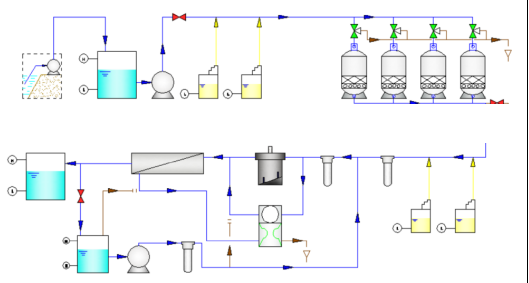

Layout of sand filtration system

| Component Name | FGC028 Configuration | FGC035 Configuration | FGC045 Configuration | FGC065 Configuration | Quantity | Material | Supplier |

|---|

| Filter Tank | 3×Φ600 | 3×Φ600 | 4×Φ600 | 4×Φ750 | 1 Set | FRP | Jieming |

| Sand Weight | 1.2 Ton | 1.2 Ton | 1.6 Ton | 2.6 Ton | 1 Set | - | HAFE |

Reverse osmosis system layout diagram

| Component Name | FGC028 Configuration | FGC035 Configuration | FGC045 Configuration | FGC065 Configuration | Quantity | Material | Supplier |

|---|

| Pre-filter | 1μm Nominal Filtration | 1μm Nominal Filtration | 1μm Nominal Filtration | 1μm Nominal Filtration | 1 Unit | UPVC/FRP | China |

| Main Filter | 5μm Absolute Filtration | 5μm Absolute Filtration | 5μm Absolute Filtration | 5μm Absolute Filtration | 1 Unit | UPVC/FRP | China |

| High-Pressure Pump (with VFD) | Axial Piston Pump | Axial Piston Pump | Axial Piston Pump | Axial Piston Pump | 1 Unit | SS2507 | Danfoss |

| Membrane Housing | 1×3 + 1×2 | 2×3 | 4×2 | 4×3 | 1 Set | FRP | ROPV |

| Reverse Osmosis Membrane (Type 8040) | 5 Pcs | 6 Pcs | 8 Pcs | 12 Pcs | 1 Set | Composite Material | Nano H2O |

| Frame | With Anti-Corrosion Coating | With Anti-Corrosion Coating | With Anti-Corrosion Coating | With Anti-Corrosion Coating | 1 Set | CS | HAFE |

| High-Pressure Pipeline | PN100 | PN100 | PN100 | PN100 | 1 Set | SS2205 | HAFE |

| Low-Pressure Pipeline | PN10 | PN10 | PN10 | PN10 | 1 Set | UPVC | Hershey |

| Container | 20ft | 20ft | 20ft | 20ft | 1 Unit | CS | China |

| Component Name | Universal Configuration for FGC028-FGC065 | Quantity | Material | Supplier |

|---|

| Flushing/CIP Pump | Single-Stage or Multi-Stage Centrifugal Pump | 1 Unit | SS316 | CNP |

| CIP Filter | 20μm Pleated Cartridge | 1 Unit | PP | China |

| CIP Tank | FGC028/FGC035: 200L; FGC045/FGC065: 400L/600L | 1 Unit | PE | Jiangnan |

| Dosing Pump | 4 Units | 1 Set | Pump Body: Plastic | Miltonroy |

| Dosing Tank | 4 Units | 1 Set | PE | Jiangnan |

| Component Name | Specification Parameter | Quantity | Material/Configuration | Supplier |

|---|

| Pressure Gauge (0-10bar) | Anti-Vibration | 7 Units | Contact Surface: SS316L/PP | China |

| Pressure Gauge (0-100bar) | Anti-Vibration | 1 Unit | Contact Surface: SS316L | Wika |

| Electric Contact Pressure Gauge (0-100bar) | Anti-Vibration | 1 Unit | Contact Surface: SS316L | Wika |

| Low-Pressure Switch | Range: 0-10bar | 1 Unit | Contact Surface: Nickel-Plated | Danfoss |

| ORP Meter | Online Type | 1 Unit | Composite Material | Suntex |

| Product Water Conductivity Meter | Online Type (0-2000μs/cm) | 1 Unit | Composite Material | Suntex |

| Product Water Flow Meter | Paddle Wheel Type | 1 Unit | Plastic | Lucenline |

| Feed/Brine/CIP Flow Meter | Rotor Type | 3 Units | Plastic | Yinhuan |

| Level Switch | Float Type (for Feed Tank/Product Tank) | 4 Units | Plastic | Fine |

| Control Cabinet | Core Components: Schneider; PLC: Siemens | 1 Unit | Housing: CS | HAFE |

| Spare Parts | O-Rings, Spare Pressure Gauges, UPVC Fittings, 1-Year Filter Kit, etc. | 1 Set | - | HAFE |

| Accessory Name | Specification | Quantity | Material | Supplier |

|---|

| Filter Kit | FGC028/FGC035: 50×2.65”; FGC045/FGC065: 70×2.65”/90×2.65” | 1 Set | PP | HAFE |

| Intake Pump & Feed Pump | HAFE Recommended Configuration | 1 Set | - | - |

| Insulation Kit | Including RO Container Insulation + Air Conditioner | 1 Set | Composite Material | HAFE |

| Touch Screen Kit | 10-Inch Delta Touch Screen + Instruments, Including SCADA Programming | 1 Set | Composite Material | HAFE |

The following is a table of technical parameters:

| Technical Parameter | Unit | FGC028 | FGC035 | FGC045 | FGC065 |

|---|

| Rated Product Flow (Standard Seawater) | m³/h | 2.8 | 3.5 | 4.5 | 6.5 |

| Rated Recovery Rate (Standard Seawater) | % | 35 | 36 | 35 | 35 |

| Minimum Inlet Pressure | barg | 4 | 4 | 4 | 4 |

| Maximum Inlet Pressure | barg | 6 | 6 | 6 | 6 |

| Minimum System Pressure | barg | 20 | 20 | 20 | 20 |

| Maximum System Pressure | barg | 70 | 70 | 70 | 70 |

| RO Membrane Specification | - | 8040 | 8040 | 8040 | 8040 |

| Quantity of RO Membranes | Pcs | 5 | 6 | 8 | 12 |

| Quantity of Membrane Housings | Pcs | 2 | 2 | 4 | 4 |

| Rated Power (at 70bar) | kW | 20 | 25 | 32 | 44 |

| Input Power Supply | - | 3-Phase 380VAC±10%, 50Hz | 3-Phase 380VAC±10%, 50Hz | 3-Phase 380VAC±10%, 50Hz | 3-Phase 380VAC±10%, 50Hz |

Notes:

The rated parameters are based on "35,000ppm, 20℃ standard seawater"; if the TDS of the feed water is lower, the water production and recovery rate can be increased; if the TDS is higher, the capacity needs to be reduced to ensure safe operation.

The system has no feed pump, so an additional intake pump/feed pump needs to be configured to meet the inlet pressure requirement.

If pressure higher than 70bar is required, please contact QT for customization.

The rated power does not include the power of the intake pump/feed pump, and the actual energy consumption is usually lower.

The power supply can be customized to other voltages and frequencies as required.

The system is flexible and suitable for various seawater desalination demand scenarios:

Island Residential Areas: Solve the problem of daily drinking water shortage for island residents and replace high-cost freshwater transportation.

Hotels/Resorts: Meet the domestic water and service water needs of coastal tourism facilities.

Construction Sites: Provide stable freshwater for coastal or remote construction sites to ensure the progress of construction projects.

Emergency Water Supply: Quickly build mobile water plants after natural disasters (tsunamis, floods) or during temporary events.

High-Salinity Groundwater Treatment: Convert inland high-salinity groundwater into drinkable freshwater to expand the sources of water resources.

For more information about the customization plan, technical details or purchase of the seawater desalination system, please contact us through the following methods:

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:FG Water Containerized SWRO and BWRO system