Dupont™ AmberLite™ IRN160 H/OH Ion Exchange Resin

As a premium pre-mixed ion exchange resin tailored for the nuclear power sector, DuPont™ AmberLite™ IRN160 H/OH stands out with nuclear-grade purity, excellent radioactivity removal, and stable long-term performance. It is a stoichiometric 1:1 mixture of AmberLite™ IRN97 H cation resin and IRN78 OH anion resin, specifically designed to meet the strict requirements of nuclear loop water treatment—effectively removing radioactive cations (e.g., ¹³⁷Cs, cobalt isotopes), anionic radioactive materials, and impurities while minimizing equipment maintenance and unscheduled outages. For nuclear power plants, fuel pool management, and rad waste treatment facilities, this resin is the trusted choice for safe, efficient, and compliant water purification.

Why Choose DuPont™ AmberLite™ IRN160 H/OH?

1. Nuclear-Grade Purity, Zero Contamination Risks

• Ultra-Low Impurity Levels: Manufactured via specialized nuclear-grade processes, inorganic impurities (Na, Fe, Co, etc.) are controlled to ≤40 mg/kg (dry basis), and soluble organic compounds are removed to trace levels. This prevents impurity activation in the reactor core, avoiding increased radioactivity and ensuring nuclear system safety.

• High Ionic Purity: As-shipped resin achieves ≥99% H⁺ conversion (cation component) and ≥95% OH⁻ conversion (anion component), with harmful anions like Cl⁻ ≤0.05% and SO₄²⁻ ≤0.1%. No pre-treatment is needed before use, reducing start-up time.

2. Efficient Radioactivity & Impurity Removal

• Dual-Action Purification: Cation resin (IRN97 H) captures radioactive cations (¹³⁷Cs, cobalt isotopes) and heavy metals; anion resin (IRN78 OH) removes anionic radioactive materials and silica. It also efficiently eliminates silver, meeting the strictest water quality standards for nuclear loops.

• High Exchange Capacity: Cation resin offers ≥2.10 eq/L (H⁺ form) capacity, anion resin ≥1.20 eq/L (OH⁻ form)—10-15% higher than standard nuclear resins. Reduces rad waste generation by minimizing resin replacement frequency.

3. Anti-Separation Design, Easy Installation & Transfer

• Minimized Layer Separation: Cation resin (525±50 μm) has a smaller particle size than anion resin (630±50 μm), preventing cation-anion separation during installation and transfer. Eliminates cation layer formation at the service vessel bottom, ensuring uniform purification.

• Fast Change-Out & Rinse: Pre-mixed formula enables quick resin replacement and initial rinse-up. Cuts start-up time by 30% and reduces rinse wastewater volume by 25%, lowering operational costs.

4. Strong Durability, Long Service Life

• Excellent Mechanical Strength: ≥95% whole uncracked beads, with friability resistance (≥400 g/bead for cation, ≥600 g/bead for anion). Withstands high-pressure backwashing and long-term use without breakage or attrition.

• Wide Operating Range: Stable at 5–100°C (41–212°F) and pH 0–14, adaptable to various nuclear water treatment scenarios (e.g., primary coolant blowdown, fuel pool purification).

Uniform pre-mixed spherical beads ensure efficient ion exchange and anti-separation performance

Key Technical Specifications (DuPont Official Data)

Parameter | AmberLite™ IRN97 H (Cation Resin) | AmberLite™ IRN78 OH (Anion Resin) | Mixture (IRN160 H/OH) |

Resin Type | Strong acid cation (gel) | Strong base anion (gel) | 1:1 equivalent mixture |

Copolymer | Styrene-divinylbenzene | Styrene-divinylbenzene | — |

Functional Group | Sulfonic acid | Trimethylammonium | — |

Physical Form | Amber, translucent spherical beads | Amber, translucent spherical beads | — |

Ionic Form (Shipped) | H⁺ (≥99% conversion) | OH⁻ (≥95% conversion) | — |

Total Exchange Capacity | ≥2.10 eq/L (H⁺ form) | ≥1.20 eq/L (OH⁻ form) | — |

Water Retention Capacity | 45.0–51.0% (H⁺ form) | 54.0–60.0% (OH⁻ form) | — |

Particle Diameter | 525±50 μm | 630±50 μm | — |

Uniformity Coefficient | ≤1.20 | ≤1.10 | — |

Max Operating Temperature | 5–100°C (41–212°F) | 5–100°C (41–212°F) | Same as components |

Shipping Weight | — | — | 700 g/L |

Key Impurity Limits (Dry Basis) | Na≤40 mg/kg, Fe≤20 mg/kg, Co≤5 mg/kg | Na≤20 mg/kg, SiO₂≤10 mg/kg, Cl⁻≤250 mg/kg | Complies with nuclear-grade standards |

Ideal Application Scenarios

DuPont™ AmberLite™ IRN160 H/OH is engineered for critical nuclear water treatment needs:

• Primary Water Treatment: Purifies primary coolant blowdown and supports pre-outage cleanup, maintaining coolant purity and preventing reactor core contamination.

• Fuel Pool Purification: Removes radioactive impurities and suspended solids in fuel pools, ensuring safe storage and handling of nuclear fuel.

• Rad Waste Treatment: Eliminates radioactive cations (¹³⁷Cs, cobalt), anionic radioactive materials, and silver from rad waste, reducing environmental impact.

• PWR/BWR Systems: Suitable for PWR steam generation blowdown (APG) and BWR condensate polishing, meeting the strict water quality requirements of pressurized/water-cooled reactors.

Purchase Information & Support

1. Packaging Options

Product SKU | Description | Packaging | Suitable For |

IRN160-HOH-200L | DuPont™ AmberLite™ IRN160 H/OH Resin | 200L industrial drum (sealed, anti-contamination) | Medium-sized nuclear facilities, routine replacement |

IRN160-HOH-BULK | DuPont™ AmberLite™ IRN160 H/OH Resin | Bulk (tanker/container, custom sealing) | Large nuclear power plants, long-term projects |

Note: All packaging meets nuclear industry contamination control standards, with batch-specific CO (Certificate of Origin) and CQ (Certificate of Quality) provided.

2. How to Buy

• Official Inquiry: Contact authorized nuclear-grade resin distributors (e.g., FG Water Technologies) for genuine products and technical consultations.

• Technical Assessment: Provide details of your application (e.g., nuclear system type, water volume, impurity targets) to our team. We offer free water quality analysis and resin dosage calculation to ensure optimal performance.

• Custom Solutions: For special nuclear scenarios (e.g., high-temperature rad waste treatment), we provide tailored resin deployment plans and on-site guidance.

3. Quality Assurance & After-Sales

• Genuine Guarantee: 100% authentic DuPont resin, traceable via DuPont’s global product tracking system. Strictly complies with ASTM D4388 (ion exchange resin standards) and nuclear industry regulations (e.g., ASME BPVC).

• Technical Support: Access to DuPont’s nuclear water treatment experts for free services: resin loading guidance, regeneration parameter setting, and troubleshooting.

• Warranty: 18-month warranty against manufacturing defects (extended for nuclear projects). If quality issues occur, we provide free replacement and on-site remediation.

Safety Precautions

WARNING: Oxidizing agents (e.g., nitric acid) may attack organic ion exchange resins under certain conditions, leading to resin degradation or violent exothermic reactions. Do not use strong oxidizing agents in the system without consulting DuPont’s technical team.

• Store resin in a cool, dry, and contamination-free environment (temperature 5–30°C, relative humidity ≤70%).

• Wear nuclear-grade protective equipment (e.g., anti-radiation gloves, dust masks) during handling to avoid contact with impurities.

FAQ

Q1: Can this resin be used in high-temperature nuclear systems above 70°C?

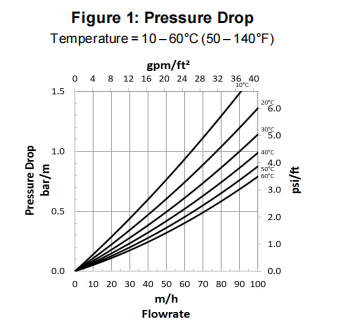

A1: The resin tolerates up to 100°C, but long-term operation above 60–70°C may affect loop purity and resin life. Our technical team will provide parameter optimization (e.g., flow rate adjustment) for high-temperature applications.

Q2: How often does the resin need replacement in nuclear coolant treatment?

A2: Replacement frequency depends on radioactivity levels and water volume. In typical primary coolant blowdown systems, replacement occurs every 18–24 months. We provide a customized replacement schedule based on your system’s radioactivity monitoring data.

Q3: Does the resin meet international nuclear industry standards?

A3: Yes. It complies with global nuclear regulations, including US NRC (Nuclear Regulatory Commission) guidelines, EU Euratom standards, and China’s GB/T 13659-2008 (ion exchange resins for nuclear power plants).

Choose DuPont™ AmberLite™ IRN160 H/OH for safe, efficient, and compliant nuclear water treatment. Contact our authorized distributors today to get a tailored solution and exclusive nuclear project support!

For inquiries, visit FG Water Technologies (authorized distributor) or call +86-13646187144 (24-hour nuclear technical support). You can also send your requirements to [email protected] for a detailed quotation and technical proposal.

Product sample download address:IER-AmberLite-IRN160-H-OH-PDS-45-D01208-en.pdf