DuPont™ AmberTec™ UP6040 OH Ion Exchange Resin High-Purity Anion Solution for Ultrapure Water Polishing

As a premium strong base anion exchange resin under DuPont’s ultrapure water (UPW) product line, AmberTec™ UP6040 OH (Part Number: UP6040 OH) is engineered to meet the strict anion removal demands of high-end industries like semiconductors, pharmaceuticals, and laboratories. This Type I strong base anion resin excels in removing soluble silica, boron, chloride, sulfate, and organic anions, delivering sub-ppb level purification to ensure ultrapure water meets the most rigorous standards. This SEO-optimized article details its core advantages, technical parameters, application scenarios, and reliable purchasing channels, helping enterprises quickly secure efficient, compliant anion purification solutions.

1. Core Advantages of DuPont™ AmberTec™ UP6040 OH: Why It’s Trusted for High-Purity Needs

① Sub-Ppb Anion Removal, Meeting Ultra-Pure Water Standards

• Targeted Contaminant Control: Specialized in removing key harmful anions—soluble silica (≤0.1 ppb), boron (≤0.5 ppb), chloride (≤0.1 ppb), sulfate (≤0.1 ppb)—critical for semiconductor photolithography, pharmaceutical injection water, and laboratory Type I water. Fully complies with SEMI F63-0308 (semiconductor UPW) and USP <1231> (pharmaceutical water) standards.

• High Exchange Capacity: Exchange capacity >1.1 eq/L ensures efficient anion adsorption per unit volume, reducing resin dosage by 15-20% compared to ordinary strong base anion resins. Low leakage rate (<0.5% Cl⁻ residual) avoids secondary pollution of ultrapure water.

② Stable Performance, Adaptable to Strict Operating Conditions

• Wide pH Compatibility: Stable operation in pH 0-14, suitable for acidic/alkaline pre-treated water polishing (e.g., post-EDI or RO water). No performance degradation in extreme pH environments, ensuring consistent anion removal.

• Optimal Particle Size Design: 630±50 μm particle size with uniformity coefficient ≤1.2, enabling uniform flow distribution in the resin bed. Reduces pressure drop (0.5-1.5 Bar/m at 10-30 m/h flow rate) and avoids channeling, lowering pump energy consumption by 10-15%.

③ Durable & Low-Maintenance, Reducing Operational Costs

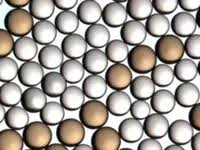

• Strong Mechanical Strength: Gel matrix (styrene-divinylbenzene copolymer) with high compression resistance, ensuring ≥95% whole uncracked beads. Resists breakage during backwashing and long-term use, extending service life to 2-3 years (vs. 1.5 years for ordinary resins).

• Low Water Content Fluctuation: Water content stabilized at 54-60%, avoiding resin volume expansion/contraction that causes bed deformation. Reduces maintenance frequency and system downtime.

④ Ultra-Clean Manufacturing, Avoiding Impurity Introduction

• Semiconductor-Grade Purity: Produced in a Class 1000 cleanroom with specialized impurity removal processes. Metal impurities (Fe, Cu, Na) are controlled to trace levels (<10 mg/kg), preventing "killer defects" in semiconductor wafers or pharmaceutical product contamination.

• Batch Consistency: Each batch undergoes DuPont’s strict quality testing (exchange capacity, leakage rate, particle size), ensuring uniform performance—critical for large-scale production lines requiring stable water quality.

2. Technical Parameters: Ensuring Reliable Anion Purification (From DuPont Official Data)

Parameter Category | Specific Indicators |

Basic Information | - Brand: DuPont Resins- Model: AmberTec™ UP6040 OH- Part Number: UP6040 OH- Type: Strong base anion resin (Type I)- Copolymer: Styrene-divinylbenzene- Matrix Structure: Gel- Physical Form: White to yellow, translucent spherical beads |

Chemical Properties | - Exchange Capacity: >1.1 eq/L- Water Content: 54-60%- Ionic Residual: Cl⁻ ≤0.5%- Functional Group: Trimethylammonium |

Physical Properties | - Particle Size: 630±50 μm- Uniformity Coefficient: ≤1.2- Shipping Weight: 710 g/L- Whole Uncracked Beads: ≥95% |

Operating Conditions | - Maximum Operating Temperature: 25°C (77°F, optimal for UPW)- pH Range (Stable): 0-14- Application: Non-regenerable polishing mixed beds, standalone anion polishing |

3. Typical Application Scenarios: Covering High-End Anion Purification Needs

DuPont™ AmberTec™ UP6040 OH is widely used in scenarios where anion control is critical:

• Semiconductor Industry: Polishing of ultrapure water for 7nm and below chip fabrication (e.g., photolithography lens cleaning, wafer etching). Removes silica/boron to avoid circuit defects caused by anion impurities.

• Pharmaceutical Industry: Anion polishing of injection water and bulk pharmaceutical water, ensuring compliance with EP (European Pharmacopoeia) and CP (Chinese Pharmacopoeia) standards. Prevents anion-induced drug degradation.

• Laboratory Ultra-Pure Water: Preparation of Type I water for analytical instruments (HPLC, mass spectrometry), meeting ASTM D1193 Type I water requirements (resistivity ≥18.2 MΩ·cm, TOC ≤5 ppb).

• Electronic Component Manufacturing: Purification of water for LED, lithium battery, and precision capacitor production. Removes chloride/sulfate to avoid corrosion of metal components.

4. Purchase Information: Choose FG Water for Authenticity & Professional Support

To ensure you obtain genuine DuPont™ AmberTec™ UP6040 OH resin and enjoy professional technical services, purchase through FG Water Technologies (official website: https://www.fgwater.com/), an authorized DuPont distributor.

① Packaging Options

Product SKU | Description | Packaging | MOQ | Suitable For |

UP6040-OH-200L | DuPont™ AmberTec™ UP6040 OH Resin | 200L sealed HDPE drum (cleanroom-grade, anti-contamination) | 1 drum | Medium-sized semiconductor plants, laboratory UPW systems |

UP6040-OH-BULK | DuPont™ AmberTec™ UP6040 OH Resin | Bulk (custom sealed container, nitrogen-protected) | 1 batch | Large semiconductor fabs, long-term UPW maintenance projects |

Note: All packaging includes batch-specific Certificate of Analysis (CoA) and Safety Data Sheet (SDS) for traceability.

② How to Purchase & Consult

• Official Website Inquiry: Visit FG Water Official Website, enter "International Brand Resins" → search "AmberTec UP6040 OH" to view details and submit an inquiry. The team replies within 24 hours.

• Direct Contact:

◦ 24-hour Technical Support: +86-13646187144 (Phone/WhatsApp, for urgent anion purification consultations)

◦ Business Cooperation: +86-510-85163211 (Weekdays 9:00-18:00, for quotes and customized solutions)

• Email Communication: Send your needs (water volume, target anion levels, application scenario) to [email protected]. FG Water provides free resin dosage calculation and system matching guidance.

③ Quality Assurance & After-Sales

• Genuine Guarantee: 100% authentic DuPont resin, traceable via DuPont’s global product tracking system. Strictly excludes counterfeit or refurbished products.

• Technical Support: Free services include resin loading guidance, backwash parameter setting, and on-site debugging. For large projects, DuPont’s anion resin experts can provide on-site support.

• Warranty Service: 12-month warranty against manufacturing defects. If anion leakage exceeds standards, free replacement and technical remediation are provided.

5. FAQ: Solving Common Anion Purification Doubts

Q1: Can this resin be used in high-temperature ultrapure water systems?

A1: The optimal operating temperature is 25°C. Operating above 60°C may reduce exchange capacity and increase TOC leakage. For high-temperature scenarios (40-50°C), consult our team for high-temperature-resistant resin alternatives or parameter adjustments.

Q2: How to match with cation resins for mixed bed polishing?

A2: Recommended pairing with DuPont™ AmberTec™ UP6040 H cation resin (525±50 μm) in 1:1 volume ratio. The combination achieves 18.2 MΩ·cm ultrapure water, suitable for semiconductor final polishing. FG Water provides free mixed bed ratio design based on your water quality.

Q3: What’s the difference between Type I and Type II strong base anion resins?

A3: Type I (AmberTec™ UP6040 OH) has higher anion selectivity (especially for silica/boron) and chemical stability, suitable for high-purity water; Type II has higher exchange capacity but lower stability, suitable for general industrial demineralization. This resin is preferred for ultrapure water scenarios.

6. Contact Information (FG Water Technologies Official)

• Official Website: https://www.fgwater.com/ (Browse anion resins, download technical documents, submit inquiries)

• 24-hour Technical Support: +86-13646187144 (Phone/WhatsApp)

• Business Hotline: +86-510-85163211 (Weekdays 9:00-18:00)

• Official Email: [email protected] (For quotes, technical solutions, sample applications)

Choose DuPont™ AmberTec™ UP6040 OH for efficient, stable anion purification. Contact FG Water today to get a customized solution and exclusive bulk purchase discounts for semiconductor/pharmaceutical projects!