28000GPD Commercial Reverse Osmosis Water Treatment Systems - BWRO & SWRO for Industrial Use

Product Overview

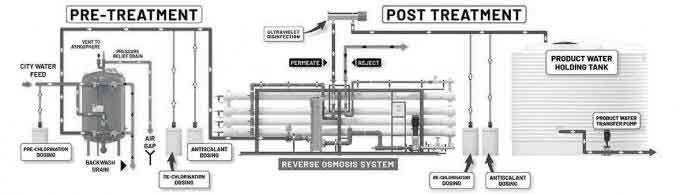

The 28000GPD Commercial Reverse Osmosis Water Treatment System offers a high-performance solution for purifying water from various sources, including brackish and seawater. This BWRO - Brackish Water Reverse Osmosis System is designed to produce low dissolved solids water, ideal for industries like beverage production, pharmaceutical applications, food processing, hotels, hospitals, and more. With a robust design and customizable features, it ensures reliable and efficient operation for a wide range of water purification needs.

For seawater treatment, the SWRO - Seawater Reverse Osmosis System offers similar benefits but tailored to handle higher salt concentrations. Both systems are engineered for long-term use with excellent performance under varying water quality conditions.

Key Features of BWRO and SWRO Systems

High Efficiency: Advanced RO membranes (Vontron, Hydranautics, or DOW) remove up to 99.7% of salts and other contaminants.

Flexible Voltage Options: Available in 220V, 380V, and 415V for customized operation based on local power supplies.

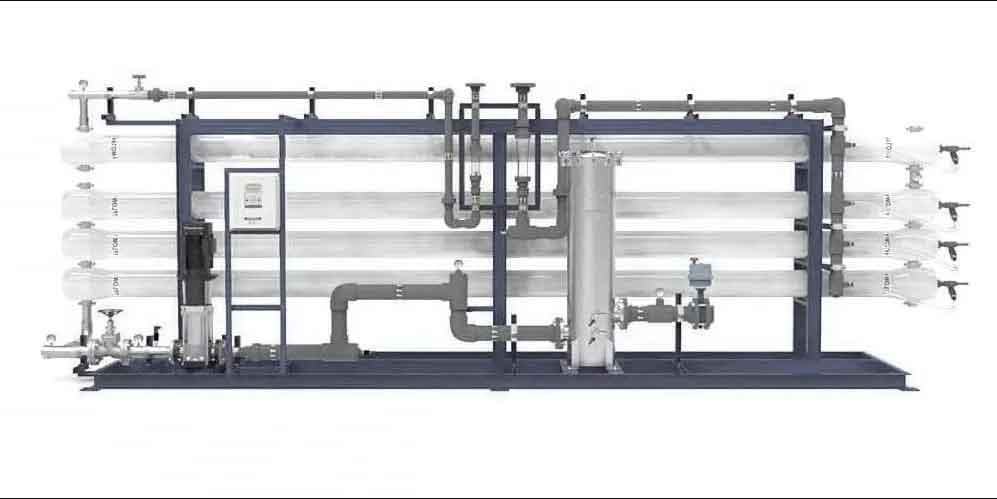

Skid-Mounted Design: Compact and space-saving, perfect for installation in limited space areas.

Wide Application Range: Suitable for metal finishing, bottled water, beverage production, power plants, food and beverage processing, laboratory use, and more.

Customizable Recovery Rates: Recovery rates range from 65% to 75%, with an ability to operate at TDS levels up to 2,000 ppm.

Tough Construction: Made from high-quality SS304/SS316L stainless steel and carbon steel, offering durability and long-term reliability.

Easy Operation: Equipped with user-friendly electronic, manual, or PLC controls with an LCD screen and real-time performance monitoring.

Technical Specifications & Models

| Model Number | Permeate Flow Rate (GPD) | Membranes (Qty) | Pressure Vessel (Qty) | Motor Rating (HP) | Approx. Weight (LBS) | Dimensions (LxWxH, in) | Dimensions (LxWxH, cm) |

|---|

| ROM-1480 | 28,000 | 4 | 1 | 5 | 2300 | 170x33x58 | 432x84x147 |

| ROM-1580 | 36,000 | 5 | 1 | 7.5 | 2350 | 210x33x58 | 533x84x147 |

| ROM-1680 | 43,000 | 6 | 1 | 7.5 | 2400 | 250x36x58 | 635x91x147 |

| ROM-2480 | 57,000 | 8 | 2 | 7.5 | 2500 | 170x36x58 | 432x91x147 |

| ROM-2580 | 72,000 | 10 | 2 | 10 | 2600 | 210x36x58 | 533x91x147 |

| ROM-3480 | 87,000 | 12 | 3 | 15 | 2700 | 170x48x66 | 432x122x168 |

| ROM-3580 | 108,000 | 15 | 3 | 20 | 3200 | 210x48x66 | 533x122x168 |

| ROM-3680 | 130,000 | 18 | 3 | 20 | 3500 | 250x62x66 | 635x157x168 |

| ROM-4580 | 144,000 | 20 | 4 | 20 | 4200 | 210x62x66 | 533x157x168 |

| ROM-4680 | 173,000 | 24 | 4 | 20 | 4550 | 250x62x66 | 635x157x168 |

Operating Conditions

Max Feed Water Temperature: 42°C

Max Silica Tolerance: 25 ppm at 60% recovery

Max Iron Content: 0.05 ppm

Operating Pressure: 150 to 250 psi

Feed Water Pressure: 20 to 80 psi

Turbidity: Should be removed

Max Feed Water TDS: Up to 5,000 ppm (depending on the model)

PH Range: 3-11

Standard Features

4" TFC Spiral Wound Membranes

Stainless Steel Multi-Stage Pump with TEFC Motor

FRP Membrane Housings

5-Micron Cartridge Prefilter

Microprocessor-Based Control Panel

Programmable Time Delay and Set Points

LCD Screen Display

Low and High-Pressure Switches

Liquid-Filled Pressure Gauges

Permeate Conductivity Monitor

Permeate & Concentrate Flow Meters

Remote Monitoring Option

Available Options

Applications of BWRO & SWRO Systems

Beverage Production: Purified water for consistent taste and quality in juices, sodas, and other drinks.

Bottled Water: Reliable filtration for high-quality bottled water production.

Pharmaceutical: Meets the stringent water quality requirements for pharmaceutical manufacturing.

Food Processing: Ensures safe water for food processing, reducing contamination risks.

Power Plants: Provides high-purity water for steam generation and cooling systems.

Cooling Towers: Purified water for cooling systems in large facilities.

Electronics & Semiconductor: Removes impurities in water used for sensitive electronics manufacturing.

Chemical Blending: Water purification for various chemical formulations.

Why Choose Our Commercial Reverse Osmosis Systems?

The 28000GPD Commercial Reverse Osmosis Water Treatment Systems are engineered to provide efficient, cost-effective solutions for industrial water treatment. With customizable recovery rates, robust construction, and advanced monitoring, these systems are ideal for any commercial application requiring high-quality purified water. Whether you're in the beverage, pharmaceutical, or industrial sector, our BWRO - Brackish Water Reverse Osmosis System ensures optimal water quality while minimizing operational costs.

Contact Us for More Information

For more information about our Commercial Reverse Osmosis Water Treatment Systems or to discuss your specific water treatment needs, please visit our Contact Us page or reach out via email at [email protected].

For more product details and other systems, check out our BWRO - Brackish Water Reverse Osmosis System and SWRO - Seawater Reverse Osmosis System pages.