35m³/day Domestic Sewage Treatment Project - 6-Meter Container Domestic Sewage Treatment Container Equipment Container Water Purification System

As an eco-technical enterprise integrating environmental engineering design, construction, and R&D, production, sales, installation, renovation, and maintenance of high-end environmental protection equipment, the company has taken the lead in obtaining ISO 9001 Quality Management System certification in the industry. With strong technical strength and advanced production equipment, it has more than 100 employees, including 20 engineering and technical personnel, and a total asset of 50 million yuan. The company covers an area of 25,000 square meters, with a 15,000-square-meter workshop equipped with dozens of top-tier processing and testing equipment such as CNC machining centers, gantry boring and milling machines, CNC wire cutting machines, and automatic batching machines.

The company has established a sound product development, quality control, and after-sales service system, and possesses integrated capabilities in independent R&D, design, manufacturing, installation, commissioning, and maintenance services. Up to now, it has successfully undertaken thousands of projects involving municipal sewage, domestic sewage, urban reclaimed water, as well as industrial wastewater and waste gas treatment in industries such as chemical engineering, textile printing and dyeing, coating, food processing, starch production, papermaking, pharmaceuticals, mining, and leather.

The company owns a number of patented environmental protection solutions, including integrated ABR sewage treatment systems, high-concentration sewage treatment equipment, combined domestic sewage treatment devices, BAF aeration treatment equipment, coal slime dewatering systems, new dissolved air flotation machines, and UASB high-efficiency anaerobic reactors. Its products are sold well in both domestic and international markets, among which the dissolved air flotation machines and ABR integrated systems are the company's proprietary technologies.

According to the data provided by Party A, the sewage to be treated in this project is domestic sewage from residents, with a maximum daily sewage discharge of 35 m³/day. In accordance with Party A's requirements, the designed treatment capacity of this project is Q = 35 t/day. Calculated based on 20 hours of daily operation, the designed treatment capacity is 1.75 m³/h, which meets the sewage treatment needs.

Since Party A has not provided detailed water quality data, the influent water quality is designed based on Party A's suggestions and the research results of similar domestic sewage. The main pollutant indicators are shown in the following table:

| Item | Influent Water Quality (mg/L) |

|---|

| CODCr (mg/L) | 150~350 |

| BOD5 (mg/L) | 100~200 |

| SS (mg/L) | 200~300 |

| PH (Dimensionless) | 6.0~9.0 |

| Ammonia Nitrogen (mg/L) | 30~50 |

| Total Phosphorus (mg/L) | 3~5 |

In accordance with Party A's requirements, it is ensured that the effluent water quality indicators meet or exceed the national urban greening water quality standard limits specified in Urban Sewage Recycling and Reuse - Quality of Urban Miscellaneous Water (GB/T 18920-2020). The effluent water quality is shown in the following table:

| Item | Effluent Water Quality |

|---|

| pH | 6.0~9.0 |

| Color (Degree) | ≤15 |

| Odor | No unpleasant smell |

| Turbidity (NTU) | ≤10 |

| BOD5 (mg/L) | ≤10 |

| NH3-N (mg/L) | ≤8 |

| Anionic Surfactant (mg/L) | ≤0.5 |

| Total Residual Chlorine (mg/L) | ≥1.0 for effluent from plant, ≥0.2 at the end of pipe network |

| pH | 6.0~9.0 |

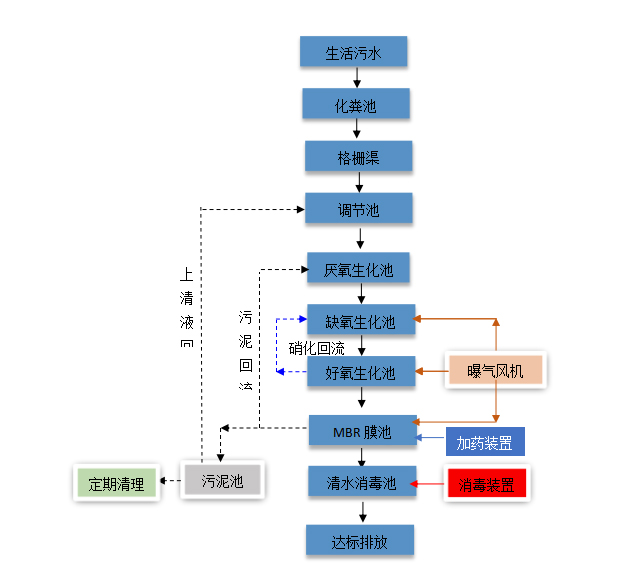

Domestic Sewage → Grating Tank → Regulating Tank → Integrated Sewage Treatment System (Anaerobic Biochemical Tank → Anoxic Biochemical Tank → Aerobic Biochemical Tank → MBR Membrane Tank → Clear Water Disinfection Tank) → Discharge up to Standard; Excess Sludge from Integrated Sewage Treatment System → Sludge Tank → Regular Transportation and Treatment, and Supernatant from Sludge Tank → Reflux to Regulating Tank/Anoxic Contact Oxidation Tank for Re-treatment.

The grating tank is used to intercept large pieces of debris and suspended solids in the sewage, preventing such debris from clogging the water pump and affecting the subsequent treatment processes. The debris intercepted by the grating should be regularly loaded into a cart and transported to a garbage dump for disposal.

After being intercepted by the grating, the sewage flows into the regulating tank by gravity. The core function of the regulating tank is to adjust the water quality and quantity of the sewage, ensuring the balance and stability of the influent water quality and quantity of the subsequent biochemical treatment system, avoiding the impact of sewage flow peaks or concentration changes, and improving the impact resistance and treatment effect of the entire system.

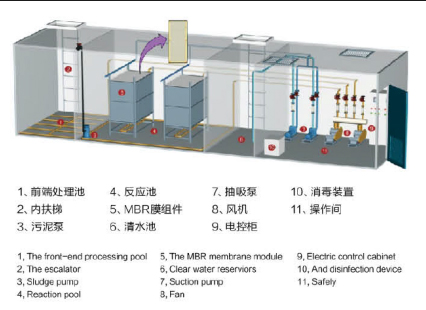

A submersible pump is installed at the end of the regulating tank to pump the sewage into the integrated treatment equipment for treatment. This system includes treatment units such as anaerobic biochemical tank, anoxic biochemical tank, aerobic biochemical tank, MBR membrane tank, and clear water disinfection tank. It adopts underground installation, which can reduce the project's floor area.

Anaerobic Biochemical Tank: In the anaerobic tank, the sewage is decomposed by anaerobic microorganisms, converting complex organic compounds into substances such as methane and carbon dioxide, realizing the transformation of harmful pollutants into harmless by-products. Its hydrolysis and acidification process can be divided into two stages according to the types of microorganisms: the first stage is the hydrolysis and acidification stage, in which complex macromolecular and insoluble organic matter are decomposed into small-molecular and soluble organic matter under the action of extracellular enzymes, and then further decomposed into volatile organic acids, alcohols, aldehydes, etc. (mainly high-level fatty acids) after entering the cells; the second stage is the hydrogen and acetic acid production stage, in which hydrogen-producing and acetic acid-producing bacteria convert the organic acids produced in the first stage into acetic acid and hydrogen.

Anoxic Biochemical Tank: After anaerobic hydrolysis, the sewage flows into the anoxic biochemical tank by gravity. As the core unit of biological treatment, this tank uses the organic matter in the influent as the carbon source and energy source for denitrification, and uses the nitrate nitrogen in the return water as the oxygen source. With the help of the biofilm (containing facultative bacteria communities) on the elastic filler in the tank, pollutants such as NH3-N and COD are effectively removed and degraded through nitrification-denitrification reactions.

Contact Oxidation Tank (Aerobic Biochemical Tank): The biochemical treatment section not only removes COD in the sewage but also removes ammonia nitrogen. The ammonia nitrogen removal process is divided into two steps: first, aerobic bacteria oxidize NH3-N into NO2- and NO3-, and then anaerobic denitrifying bacteria convert NO2- and NO3- into N2 through denitrification, among which the anoxic zone is the key part of the denitrification system. At present, the membrane-based anoxic biological treatment technology has the highest denitrification efficiency and good economy.

The contact oxidation process combines the advantages of the activated sludge method and the biofilm method. Fillers are installed in the aeration tank, and oxygen is supplied through aeration. Microorganisms are partially attached and partially suspended. Its core characteristics include:

① The filler has a large specific surface area and excellent oxygen supply conditions, and the biomass per unit volume is higher than that of the activated sludge tank and biofilter, resulting in higher volume load;

② The amount of attached microorganisms is large and the water flow is in a completely mixed mode, which has strong adaptability to sudden changes in water quality and quantity (high impact load resistance);

③ No or only a small amount of sludge return is required;

④ The tank body is compactly designed, occupying less land and having low investment cost;

⑤ The operation is simple, and no complex automatic control is needed;

⑥ Sludge bulking can be effectively prevented by sludge fixation technology.

MBR Membrane Tank: Membrane Bioreactor (MBR) is a new type of water treatment technology that combines advanced membrane separation technology with the activated sludge method. It uses hollow fiber membranes to replace the secondary sedimentation tank in the sludge method, realizing efficient solid-liquid separation and complete sludge-water separation. Relying on the high-efficiency filtration capacity of the membrane, nitrifying bacteria can be effectively retained in the reactor, ensuring the smooth progress of nitrification to remove ammonia nitrogen while avoiding sludge loss; it can also retain refractory macromolecular organic matter, extending their residence time in the reactor to achieve full decomposition. After adopting MBR technology, the removal rates of main pollutants can reach COD ≥ 93% and SS = 100%. The effluent has almost zero suspended solids and turbidity, with stable and excellent water quality, which can realize the resource utilization of sewage.

Clear Water Disinfection Tank: The contact disinfection tank is a structure that mixes disinfectant with sewage for disinfection. After the effluent from the membrane tank enters the disinfection tank, the sewage is disinfected by adding disinfectant and then discharged up to the standard. Its core function is to kill pathogenic microorganisms in the treated sewage and ensure that the effluent meets the discharge standards.

The sludge tank is a unit for sludge storage. The excess sludge generated in the biochemical section is discharged into the sludge tank. After nitrification and volume reduction of the sludge in the tank, it is regularly transported and treated; the supernatant is returned to the regulating tank/anoxic contact oxidation tank for re-treatment to avoid secondary pollution.

The equipment room is a place for placing equipment, mainly equipped with key equipment such as aeration fans, control systems, and disinfection equipment, providing power and control support for the operation of the entire sewage treatment system.

| Serial Number | Name | Internal Diameter Size | Quantity | Effective Volume | Structural Form |

|---|

| 1 | Grating Tank | - | 1 set | - | Using existing facilities |

| 2 | Regulating Tank | - | 1 set | 40 m³ | Using existing facilities |

| Serial Number | Affiliated Unit | Sub-unit | Equipment Name | Specification and Parameters | Quantity | Brand |

|---|

| 1 | Grating Channel, Regulating Tank | Grating Channel, Regulating Tank | Manual Grating | Size: 500×500 mm, Grid Gap: 10 mm; Frame: Angle Steel, Grid Mesh: Stainless Steel, Frame Material: Carbon Steel with Anti-corrosion | 1 set | FENIGAL |

| 2 | - | - | Submersible Sewage Pump | Model: WQ5-8-0.37; Flow Rate: 5 m³/h, Head: 8 m, Power: 0.37 kw | 1 unit | Kaifeng Pump Industry |

| 3 | - | - | Liquid Level Controller | KEY-4 High and Low Liquid Level Float | 1 set | Electrical Appliance |

| 4 | Integrated Treatment Equipment | Integrated Treatment Equipment | Equipment Body (Underground Type) | Size: 6×2.4×2.5 m, including Anaerobic Tank, Anoxic Tank, Aerobic Tank, MBR Membrane Tank, Disinfection Tank, Sludge Tank, Equipment Room; Material: Container Corrugated Carbon Steel with Anti-corrosion (6 mm) | 1 unit | FENIGAL |

| 5 | - | - | Internal Anti-corrosion | Shot Blasting for Rust Removal (Grade Sa2.5 and Above), Coating with Anti-rust Primer + Epoxy Bitumen Paint (3 Coats) | 1 item | FENIGAL |

| 6 | - | - | External Anti-corrosion | Shot Blasting for Rust Removal (Grade Sa2.5 and Above), Coating with Anti-rust Primer + Topcoat | 1 item | FENIGAL |

| 7 | - | - | Strengthening Treatment | Internal Steel Structure Reinforcement, Shot Blasting for Rust Removal (Grade Sa2.5 and Above) | 1 item | FENIGAL |

| 8 | Anaerobic Tank | Anaerobic Tank | Inspection Hole | Size: 500×500×200 mm | 1 set | FENIGAL |

| 9 | - | - | Water Distribution Device | DN40, Carbon Steel with Anti-corrosion | 1 set | FENIGAL |

| 10 | - | - | Elastic Filler | Specification: Φ150×2000 mm, Filling Rate: ≥70%; Suspension Method: Vertical Suspension (Inclination Angle: 90°); Effective Attached Biomass on Filler: ≥6 kg/m², Proportion of Nitrifying Bacteria in Attached Biomass: ≥4%; Specific Surface Area: ≥700 m²/m³ | 1 set | FENIGAL |

| 11 | - | - | Filler Support | Steel Plate Assembly, Shot Blasting for Rust Removal (Grade Sa2.5 and Above) | 1 set | FENIGAL |

| 12 | - | - | Effluent Weir | Saw-tooth Shape, 100×100 mm | 1 set | FENIGAL |

| 13 | Anoxic Tank | Anoxic Tank | Inspection Hole | Size: 500×500×200 mm | 1 set | FENIGAL |

| 14 | - | - | Water Distribution Device | DN60 | 1 set | FENIGAL |

| 15 | - | - | Elastic Filler | Specification: Φ150×1400 mm, Filling Rate: ≥70%; Suspension Method: Vertical Suspension (Inclination Angle: 90°); Effective Attached Biomass on Filler: ≥6 kg/m², Proportion of Nitrifying Bacteria in Attached Biomass: ≥4%; Specific Surface Area: ≥700 m²/m³ | 1 set | FENIGAL |

| 16 | - | - | Filler Support | Steel Plate Assembly, Shot Blasting for Rust Removal (Grade Sa2.5 and Above) | 1 set | FENIGAL |

| 17 | - | - | Aeration Device | Specification: Φ215 Microporous Aeration Head; Service Area: 0.25-0.55 m²/unit, Average Pore Size of Working Membrane: 80-100 μm; Air Flow: 1.5-3 m³/h; Oxygen Utilization Rate: 18.4-27.7%; Oxygenation Capacity: 0.112-0.185 KgO₂/m³h; Oxygenation Power Efficiency: 4.46-5.19 KgO₂/kwh; Aeration Resistance: 180-280 mmH₂O | 1 set | FENIGAL |

| 18 | - | - | Aeration Pipeline | Specification: Φ50 Main and Branch Pipes; Material: UPVC; Pressure: 1.0 MPa | 1 set | FENIGAL |

| 19 | - | - | Effluent Weir | Saw-tooth Shape, 100×100 mm | 1 set | FENIGAL |

| 20 | Aeration Tank | Aeration Tank | Inspection Hole | Size: 500×500×200 mm | 1 set | FENIGAL |

| 21 | - | - | Water Distribution Device | DN80 | 1 set | FENIGAL |

| 22 | - | - | Elastic Filler | Specification: Φ150×2000 mm, Filling Rate: ≥70%; Suspension Method: Vertical Suspension (Inclination Angle: 90°); Effective Attached Biomass on Filler: ≥6 kg/m², Proportion of Nitrifying Bacteria in Attached Biomass: ≥4%; Specific Surface Area: ≥700 m²/m³ | 1 set | FENIGAL |

| 23 | - | - | Filler Support | Steel Plate Assembly, Shot Blasting for Rust Removal (Grade Sa2.5 and Above) | 1 set | FENIGAL |

| 24 | - | - | Aeration Device | Specification: Φ215 Microporous Aeration Head; Service Area: 0.25-0.55 m²/unit, Average Pore Size of Working Membrane: 80-100 μm; Air Flow: 1.5-3 m³/h; Oxygen Utilization Rate: 18.4-27.7%; Oxygenation Capacity: 0.112-0.185 KgO₂/m³h; Oxygenation Power Efficiency: 4.46-5.19 KgO₂/kwh; Aeration Resistance: 180-280 mmH₂O | 1 set | FENIGAL |

| 25 | - | - | Aeration Pipeline | Specification: Φ50 Main and Branch Pipes; Material: UPVC; Pressure: 1.0 MPa | 1 set | FENIGAL |

| 26 | - | - | Effluent Weir | Saw-tooth Shape, 100×100 mm | 1 set | FENIGAL |

| 27 | - | - | Nitrification Reflux Pump | Model: WQ10-12-0.75; Flow Rate: 10 m³/h, Head: 12 m, Power: 0.75 kw | 1 unit | Kaifeng Pump Industry |

| 28 | MBR Membrane Tank | MBR Membrane Tank | Inspection Hole | Size: 500×500×200 mm | 1 set | FENIGAL |

| 29 | - | - | MBR Membrane Module | Model: ZY-MBR-1; Size: 630×1000×36 mm, Effective Membrane Area: 10 m²/curtain, Membrane Filament Diameter: 2.3 mm, Filtration Precision: 0.1 μm; End Material: ABS, Connecting Pipe Specification: Φ32 mm; Membrane Material: Polyvinylidene Fluoride (PVDF) + Polyester (PET) Support Tube; Adopting Immersed Suction Filtration Mode with Water Collection at Both Ends | 250 m² | FENIGAL |

| 30 | - | - | Membrane Support | Stainless Steel Accessories | 1 set | FENIGAL |

| 31 | - | - | Liquid Level Controller | KEY-4 High and Low Liquid Level Float | 1 set | Electrical Appliance |

| 32 | - | - | Sludge Reflux Pump | Model: WQ5-8-0.37; Flow Rate: 5 m³/h, Head: 8 m, Power: 0.37 kw | 1 unit | Kaifeng Pump Industry |

| 33 | Clear Water Tank | Clear Water Tank | Inspection Hole | Size: 500×500×200 mm | 1 set | FENIGAL |

| 34 | Equipment Room | Equipment Room | Aeration Fan | Model: HC25S | 1 unit | Baited |

| 35 | - | - | Self-priming Pump | Model: JET370; Flow Rate: 2 m³/h, Head: 16 m, Maximum Suction Lift: 9 m, Power: 0.37 kw; Pipe: DN25 | 1 unit | Xinjie Pump Industry |

| 36 | - | - | Electric Water Production Valve | DN25 PN1.0 | 1 piece | - |

| 37 | - | - | Backwash Pump | Model: JET370; Flow Rate: 2 m³/h, Head: 16 m, Maximum Suction Lift: 9 m, Power: 0.37 kw; Pipe: DN25 | 1 unit | Xinjie Pump Industry |

| 38 | - | - | Backwash Solenoid Valve | DN25 PN1.0 | 1 piece | - |

| 39 | - | - | Vacuum Pressure Gauge | Measurement Range: -0.1-0 MPa | 1 piece | - |

| 40 | - | - | Dosing Device | Model: ZYJY-200L | 1 set | FENIGAL |

| 41 | - | - | Chemical Tank | Volume: 200 L, Size: Φ560×920 mm, Material: PE | 1 unit | FENIGAL |

| 42 | - | - | Mixer | Model: BLD09-0.75 kw; Three-blade Type, Shaft and Impeller Material: Stainless Steel | 1 unit | FENIGAL |

| 43 | - | - | Metering Pump | Electromagnetic Metering Pump, Flow Rate: 0-20 L/h, Pump Head Material: PVC | 1 unit | FENIGAL |

| 44 | - | - | Disinfection Dosing Device | Model: ZYXD-100; Size: 450×400×950 mm; Voltage/Power: 220 V, 0.05 KW; Including Liquid Level Gauge and Low Liquid Level Alarm | 1 unit | FENIGAL |

| 45 | - | - | Control Panel | Model: PD-A1C; Output: 10 A/220 V, Working Voltage: AC 180 V-230 V | 1 set | - |

| 46 | - | - | Chemical Storage Tank | Volume: 100 L, Material: U-PVC | 1 unit | FENIGAL |

| 47 | - | - | Metering Pump | Flow Rate: 0-9 L/h (Adjustable); Power: 25 W; Including Back Pressure Valve, Outlet Pipe: UPVC-DN15 | 1 unit | FENIGAL |

| 48 | - | - | Control Cabinet | Control Mode: PLC + Touch Screen (Manual/Auto Integration) | 1 set | FENIGAL |

| 49 | - | - | Cabinet Body | Carbon Steel Spray-coated Cabinet | 1 set | - |

| 50 | - | - | Components | Including Circuit Breaker, Time Relay, Circuit Breaker, Indicator Light, Knob, Emergency Stop Button, Wire Trough, Cable, etc. | 1 set | Zhengtai Components |

| 51 | Installation Accessories | Installation Accessories | Wires and Cables | Meeting On-site Connection Requirements | 1 item | Purchased by User |

| 52 | - | - | Pipes and Valves | Meeting On-site Connection Requirements | 1 item | Purchased by User |

For custom requirements, please contact us:

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/