70m³/day Domestic Sewage Treatment Project Plan - 12-Meter Container: Domestic Sewage Treatment Container Equipment Container Water Purification System

1. Company Profile

The company is a high-tech environmental protection enterprise integrating environmental engineering design, construction, and R&D, production, sales, installation, renovation, and maintenance of advanced environmental protection equipment. It took the lead in obtaining ISO 9001 Quality Management System certification in the industry.

With strong technical strength and relatively advanced production equipment, the company has more than 100 employees (including 20 engineering and technical personnel), a total asset of 50 million yuan, covers an area of 25,000 m² (with 15,000 m² of workshop space), and is equipped with dozens of first-class domestic processing and testing equipment such as large CNC machining centers, gantry boring and milling machines, CNC wire cutting machines, and automatic blanking machines.

The company has a complete internal system for product R&D, quality control, pre-sales and after-sales services, and possesses comprehensive service capabilities including independent development, design, manufacturing, installation, commissioning, and maintenance.

Up to now, it has completed over 1,000 successful cases in treating municipal sewage, domestic sewage, urban reclaimed water, as well as industrial wastewater and waste gas from industries such as chemical engineering, printing and dyeing, coating, food processing, starch production, papermaking, pharmaceuticals, mining, and leather. The company's self-developed environmental protection products cover multiple series, including integrated ABR sewage treatment equipment, integrated high-concentration sewage treatment equipment, integrated domestic sewage treatment equipment, integrated BAF aeration treatment equipment, coal slime dewatering equipment, new-type air flotation equipment, and UASB high-efficiency anaerobic reactors, which are sold well in domestic and international markets. Among them, the dissolved air flotation machine and integrated ABR equipment are patented technology products.

2. Partial Company Qualifications

3. Water Quality, Water Quantity and Treatment Requirements

3.1 Design Water Quantity

According to the data provided by Party A, the sewage is domestic sewage from residents, with a maximum daily discharge of 70 m³/day. In accordance with Party A's requirements, the designed treatment capacity of this project is Q = 70 t/day. Calculated based on 20 hours of daily operation, the designed treatment capacity is 3.5 m³/h, which meets the sewage treatment needs.

3.2 Design Water Quality

Since Party A has not provided detailed influent water quality data, the influent water quality is designed with reference to Party A's suggestions and the company's research on similar domestic sewage. The main pollutant indicators are shown in the table below:

| Item | Influent Water Quality (mg/L) |

|---|

| CODCr (mg/L) | 150~350 |

| BOD5 (mg/L) | 100~200 |

| SS (mg/L) | 200~300 |

| PH (Dimensionless) | 6.0~9.0 |

| Ammonia Nitrogen (mg/L) | 30~50 |

| Total Phosphorus (mg/L) | 3~5 |

3.3 Discharge Standards

In accordance with Party A's requirements, all indicators of the effluent shall meet or exceed the limits of the national urban greening water quality standard specified in Urban Sewage Recycling and Reuse - Quality of Urban Miscellaneous Water (GB/T 18920-2020). The effluent water quality is shown in the table below:

| Item | Effluent Water Quality (mg/L) |

|---|

| pH | 6.0~9.0 |

| Color (Degree) | ≤15 |

| Odor | No unpleasant smell |

| Turbidity (NTU) | ≤10 |

| BOD5 (mg/L) | ≤10 |

| NH3-N (mg/L) | ≤8 |

| Anionic Surfactant (mg/L) | ≤0.5 |

| Total Chlorine (mg/L) | ≥1.0 mg/L at the outlet of the plant, ≥0.2 mg/L at the end of the pipe network |

| pH | 6.0~9.0 |

4. Wastewater Treatment Process Flow

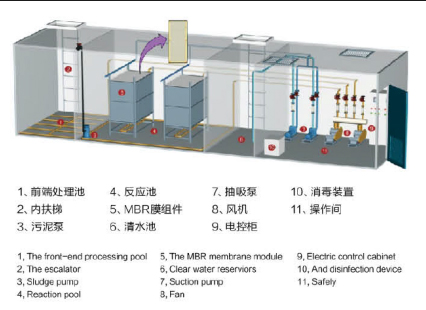

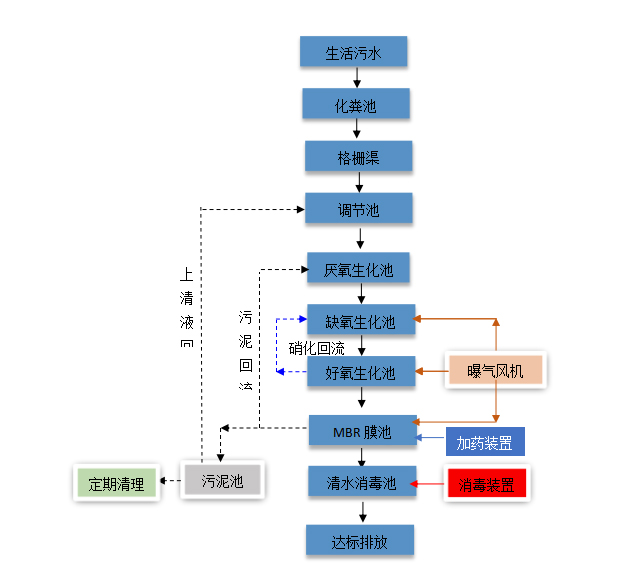

Domestic Sewage → Grating Tank → Regulating Tank → Integrated Sewage Treatment Equipment (Anaerobic Biochemical Tank → Anoxic Biochemical Tank → Aerobic Biochemical Tank → MBR Membrane Tank → Clear Water Disinfection Tank) → Discharge up to Standard; Excess Sludge from Biochemical Section → Sludge Tank (nitrification and volume reduction) → Regular Removal and Treatment; Supernatant from Sludge Tank → Reflux to Regulating Tank/Anoxic Biocontact Oxidation Tank for Secondary Treatment.

5. Description of Wastewater Treatment Process Facilities

5.1 Grating Tank

The grating tank is used to intercept large debris and suspended solids in the sewage, preventing such debris from clogging the water pump and affecting subsequent treatment processes. The debris intercepted by the grating is regularly loaded into a trolley and transported to a garbage dump for disposal.

5.2 Regulating Tank

After passing through the grating, the sewage flows into the regulating tank by gravity for adjusting the water quality and quantity. This ensures the balance and stability of the water quantity and quality of the subsequent biochemical treatment system, avoiding the impact of peak wastewater flow or concentration changes, and improving the shock resistance and treatment effect of the entire system.

5.3 Integrated Sewage Treatment Equipment

A submersible sewage pump is installed at the end of the regulating tank, which pumps the sewage into the integrated sewage treatment equipment for treatment. The integrated sewage treatment equipment includes the following treatment sections: Anaerobic Biochemical Tank + Anoxic Biochemical Tank + Aerobic Biochemical Tank + MBR Membrane Tank + Clear Water Disinfection Tank. It is buried underground to reduce the project's land occupation.

Anaerobic Biochemical Tank: In the anaerobic tank, wastewater is decomposed and converted by anaerobic microorganisms—various complex organic substances in the wastewater are broken down into methane, carbon dioxide, and other substances, thereby transforming harmful substances in the wastewater into harmless ones. The hydrolysis-acidification reaction can be roughly divided into two stages based on the type of microorganisms:

Stage 1 (Hydrolysis-Acidification Stage): Complex macromolecular and insoluble organic substances are first hydrolyzed into small-molecular and soluble organic substances under the action of extracellular enzymes, then penetrate into the cells and decompose to produce volatile organic acids, alcohols, aldehydes, etc. (higher fatty acids are the main products in this stage).

Stage 2 (Hydrogen and Acetic Acid Production Stage): Under the action of hydrogen-producing and acetic acid-producing bacteria, various organic acids produced in the first stage are decomposed and converted into acetic acid and H₂.

Anoxic Biochemical Tank: After passing through the anaerobic hydrolysis tank, the wastewater flows into the anoxic biochemical tank by gravity. The anoxic tank is one of the core facilities for biochemical treatment. Here, organic substances in the influent are used as the carbon source and energy source for denitrification, and nitrate nitrogen in the return water is used as the oxygen source for denitrification. Under the action of the biofilm (facultative bacteria clusters) on the elastic filler in the tank, nitrification and denitrification reactions occur, enabling the removal and degradation of pollutants such as NH₃-N and COD in the wastewater.

Contact Oxidation Tank (Aerobic Biochemical Tank): The biochemical treatment section needs to remove not only COD but also ammonia nitrogen from the wastewater. The ammonia nitrogen removal process is as follows: first, aerobic bacteria oxidize NH₃-N into NO₂⁻ and NO₃⁻; then, anaerobic denitrifying bacteria convert NO₂⁻ and NO₃⁻ into N₂ for release. The anoxic section is a key part of the denitrification device. Currently, the membrane-based anoxic biological treatment method is adopted, which has the best denitrification effect and is economically reliable.

The biological contact oxidation method combines the activated sludge method and the biofilm method. The aeration tank is equipped with fillers, and aeration is used for oxygenation—microorganisms are partially fixed and partially suspended. It has the following characteristics:

① Due to the large specific surface area of the fillers and good oxygenation conditions in the tank, the biomass per unit volume in the oxidation tank is higher than that in the activated sludge tank and biofilter, so it can achieve a higher volume load.

② Due to the large amount of fixed microorganisms in the tank and the completely mixed water flow, it has strong adaptability to sudden changes in water quality and quantity (high shock load resistance).

③ Little or no sludge return is required.

④ Small tank volume, small land occupation, and low investment cost.

⑤ Simple process flow, easy operation, and no need for advanced automatic control.

⑥ Sludge bulking will not occur due to the adoption of sludge fixation technology.

MBR Membrane Tank: The Membrane Bioreactor (MBR) is a new type of water treatment technology that combines efficient membrane separation technology with the activated sludge method. The application of hollow fiber membranes replaces the secondary sedimentation tank in the activated sludge method for solid-liquid separation, effectively achieving sludge-water separation.

By making full use of the efficient interception function of the membrane, nitrifying bacteria can be effectively retained and completely kept in the bioreactor, ensuring the smooth progress of nitrification to remove ammonia nitrogen and avoiding sludge loss. Additionally, it can intercept macromolecular organic substances that are difficult to degrade temporarily, extending their residence time in the reactor to achieve maximum decomposition. After applying MBR technology, the removal rates of major pollutants can reach: COD ≥ 93%, SS = 100%. The suspended solids and turbidity of the effluent are almost zero, and the treated water quality is good and stable, realizing sewage resource utilization.

Clear Water Disinfection Tank: The contact disinfection tank refers to a structure where disinfectant is mixed with sewage for disinfection. The effluent from the membrane tank enters the disinfection tank, and the sewage is disinfected by adding disinfectant before being discharged up to the standard. Its main function is to kill pathogenic microorganisms in the treated sewage to meet the discharge standards.

5.4 Sludge Tank

The sludge tank is a unit for storing sludge; the excess sludge generated in the biochemical section is discharged into the sludge tank. After the sludge in the tank undergoes nitrification and volume reduction, it is regularly cleaned and treated; the supernatant is returned to the regulating tank/anoxic biocontact oxidation tank for secondary sewage treatment, avoiding secondary pollution.

5.5 Equipment Room

The equipment room is a structure for placing equipment, mainly including aeration fans, control systems, disinfection equipment, etc.

6. List of Main Structures

| Serial Number | Name | Internal Diameter Size | Quantity | Effective Volume | Structural Form |

|---|

| 1 | Grating Tank | - | 1 set | / | Utilizing on-site existing facilities |

| 2 | Regulating Tank | - | 1 set | 40 m³ | Utilizing on-site existing facilities |

7. List of Main Process Equipment

| Serial Number | Affiliated Unit | Sub-unit | Equipment Name | Model & Specification | Quantity | Brand |

|---|

| 1 | Grating Channel

Regulating Tank | Grating Channel

Regulating Tank | Manual Grating | 500x500 mm, grid gap 10 mm; frame: angle steel, grid mesh: stainless steel, frame material: carbon steel with anti-corrosion | 1 set | FENIGAL |

| 2 | - | - | Submersible Sewage Pump | Model WQ5-8-0.37; flow rate 5 m³/h, head 8 m, power 0.37 kw | 1 unit | Kaiquan Pump Industry |

| 3 | - | - | Liquid Level Controller | KEY-4 high-low liquid level float | 1 set | Laiwen Electric |

| 4 | Integrated Treatment Equipment | Integrated Treatment Equipment | Equipment Main Body (Underground Type) | Tank size: 122.42.5 m, including anaerobic tank, anoxic tank, aerobic tank, MBR membrane tank, disinfection tank, sludge tank, equipment room; material: container corrugated carbon steel with 6 mm anti-corrosion | 1 unit | FENIGAL |

| 5 | - | - | - | Internal anti-corrosion: shot blasting for rust removal (grade Sa2.5 or above), anti-rust primer, 3 coats of epoxy coal tar pitch paint | 1 item | FENIGAL |

| 6 | - | - | - | External anti-corrosion: shot blasting for rust removal (grade Sa2.5 or above), anti-rust primer, topcoat | 1 item | FENIGAL |

| 7 | - | - | - | Reinforcing ribs: internal section steel reinforcement, shot blasting for rust removal (grade Sa2.5 or above) | 1 item | FENIGAL |

| 8 | Anaerobic Tank | Anaerobic Tank | Inspection Hole | Size 500x500x200 mm | 1 set | FENIGAL |

| 9 | - | - | Water Distribution Device | DN40, carbon steel with anti-corrosion | 1 set | FENIGAL |

| 10 | - | - | Elastic Filler | Specification: Ф150×2000 mm, filling rate ≥70%; suspension method: vertical suspension, inclination angle 90°; effective biomass attached to filler ≥6 kg/filler; proportion of nitrifying bacteria in attached biomass ≥4%; specific surface area ≥700 m²/m³ | 1 set | FENIGAL |

| 11 | - | - | Filler Bracket | Section steel assembly, shot blasting for rust removal (grade Sa2.5 or above) | 1 set | FENIGAL |

| 12 | - | - | Effluent Weir | Saw-tooth shape, 100x100 mm | 1 set | FENIGAL |

| 13 | Anoxic Tank | Anoxic Tank | Inspection Hole | Size 500x500x200 mm | 1 set | FENIGAL |

| 14 | - | - | Water Distribution Device | DN60 | 1 set | FENIGAL |

| 15 | - | - | Elastic Filler | Specification: Ф150×1400 mm, filling rate ≥70%; suspension method: vertical suspension, inclination angle 90°; effective biomass attached to filler ≥6 kg/filler; proportion of nitrifying bacteria in attached biomass ≥4%; specific surface area ≥700 m²/m³ | 1 set | FENIGAL |

| 16 | - | - | Filler Bracket | Section steel assembly, shot blasting for rust removal (grade Sa2.5 or above) | 1 set | FENIGAL |

| 17 | - | - | Aeration Device | Specification: φ215 microporous aeration head; service area: 0.25-0.55 m²/unit; average pore size of aeration membrane during operation: 80-100 μm; air flow: 1.5-3 m³/unit·h; oxygen utilization rate: 18.4-27.7%; oxygenation capacity: 0.112-0.185 KgO₂/m³h; oxygenation power efficiency: 4.46-5.19 KgO₂/kwh; aeration resistance: 180-280 mmH₂O | 1 set | FENIGAL |

| 18 | - | - | Aeration Pipeline | Specification: Φ50 main and branch pipes; material: UPVC; pressure: 1.0 MPa | 1 set | FENIGAL |

| 19 | - | - | Effluent Weir | Saw-tooth shape, 100x100 mm | 1 set | FENIGAL |

| 20 | Aerobic Tank | Aerobic Tank | Inspection Hole | Size 500x500x200 mm | 1 set | FENIGAL |

| 21 | - | - | Water Distribution Device | DN80 | 1 set | FENIGAL |

| 22 | - | - | Elastic Filler | Specification: Ф150×2000 mm, filling rate ≥70%; suspension method: vertical suspension, inclination angle 90°; effective biomass attached to filler ≥6 kg/filler; proportion of nitrifying bacteria in attached biomass ≥4%; specific surface area ≥700 m²/m³ | 1 set | FENIGAL |

| 23 | - | - | Filler Bracket | Section steel assembly, shot blasting for rust removal (grade Sa2.5 or above) | 1 set | FENIGAL |

| 24 | - | - | Aeration Device | Specification: φ215 microporous aeration head; service area: 0.25-0.55 m²/unit; average pore size of aeration membrane during operation: 80-100 μm; air flow: 1.5-3 m³/unit·h; oxygen utilization rate: 18.4-27.7%; oxygenation capacity: 0.112-0.185 KgO₂/m³h; oxygenation power efficiency: 4.46-5.19 KgO₂/kwh; aeration resistance: 180-280 mmH₂O | 1 set | FENIGAL |

| 25 | - | - | Aeration Pipeline | Specification: Φ50 main and branch pipes; material: UPVC; pressure: 1.0 MPa | 1 set | FENIGAL |

| 26 | - | - | Effluent Weir | Saw-tooth shape, 100x100 mm | 1 set | FENIGAL |

| 27 | - | - | Nitrification Reflux Pump | Model WQ10-12-0.75; flow rate 10 m³/h, head 12 m, power 0.75 kw | 1 unit | Kaiquan Pump Industry |

| 28 | MBR Membrane Tank | MBR Membrane Tank | Inspection Hole | Size 500x500x200 mm | 1 set | FENIGAL |

| 29 | - | - | MBR Membrane Module | Model ZY-MBR-1; size 630x1000x36 mm, effective membrane area 10 m²/curtain, membrane filament diameter 2.3 mm, filtration precision 0.1 μm, end material ABS, connecting pipe specification φ32 mm, membrane material: polyvinylidene fluoride (PVDF) + polyester (PET) support tube; adopts immersion suction filtration with water collection at both ends | 250 m² | FENIGAL |

| 30 | - | - | Membrane Bracket | Stainless steel accessories | 1 set | FENIGAL |

| 31 | - | - | Liquid Level Controller | KEY-4 high-low liquid level float | 1 set | Laiwen Electric |

| 32 | - | - | Sludge Reflux Pump | Model WQ5-8-0.37; flow rate 5 m³/h, head 8 m, power 0.37 kw | 1 unit | Kaiquan Pump Industry |

| 33 | Clear Water Tank | Clear Water Tank | Inspection Hole | Size 500x500x200 mm | 1 set | FENIGAL |

| 34 | Equipment Room | Equipment Room | Aeration Fan | Model HC40S | 1 unit | Best (Baishide) |

| 35 | - | - | Self-priming Pump | Model JET370; flow rate 2 m³/h, head 16 m, maximum suction lift 9 m, power 0.37 kw, with DN25 pipe | 1 unit | Xinjie Pump Industry |

| 36 | - | - | Water Production Solenoid Valve | DN25 PN1.0 | 1 piece | - |

| 37 | - | - | Backwash Pump | Model JET370; flow rate 2 m³/h, head 16 m, maximum suction lift 9 m, power 0.37 kw, with DN25 pipe | 1 unit | Xinjie Pump Industry |

| 38 | - | - | Backwash Solenoid Valve | DN25 PN1.0 | 1 piece | - |

| 39 | - | - | Vacuum Pressure Gauge | Measurement range: -0.1-0 MPa | 1 piece | - |

| 40 | - | - | Phosphorus Removal Dosing Device | ZYJY-200L | 1 set | FENIGAL |

| 41 | - | - | - | Dosing Tank: volume 200 L, size φ560x920 mm, material PE | 1 unit | FENIGAL |

| 42 | - | - | - | Mixer: BLD09-0.75 kw, three-blade type, shaft and paddle made of stainless steel | 1 unit | FENIGAL |

| 43 | - | - | - | Metering Pump: electromagnetic metering pump 0-20 L/h, pump head made of PVC | 1 unit | FENIGAL |

| 44 | - | - | Disinfection Dosing Device | Model ZYXD-100; size: 450x400x950 mm; voltage/power: 220 V, 0.05 KW; with liquid level gauge and low liquid level alarm | 1 unit | FENIGAL |

| 45 | - | - | - | Control Panel: PD-A1C, output: 10 A/220 V, power supply voltage: AC180 V-230 V | 1 set | - |

| 46 | - | - | - | Storage Tank: volume 100 L, material: U-PVC | 1 unit | FENIGAL |

| 47 | - | - | - | Metering Pump: adjustable 0-9 L/h; power: 25 W; with back pressure valve, outlet pipe UPVC-DN15 | 1 unit | FENIGAL |

| 48 | - | - | Control System | Control mode: PLC + touch screen (manual/automatic control, integrated manual and automatic) | 1 set | FENIGAL |

| 49 | - | - | - | Cabinet: carbon steel spray-coated cabinet | 1 set | - |

| 50 | - | - | - | Components: air switch, time relay, circuit breaker, indicator light, knob, emergency stop button, wire trough, cable, etc. | 1 set | Zhengtai Components |

| 51 | Installation Accessories | Installation Accessories | Wires and Cables | Meet on-site connection requirements | 1 item | Purchased by the user |

| 52 | - | - |

|

|

|

|

For custom requirements, please contact us:

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/