All-Process All-Container Integrated Water Treatment Plant (AAIWTP) - Customized Solution for Mid-to-High-End Industrial Water Purification and Wastewater Treatment

In the field of mid-to-high-end industrial water purification and wastewater treatment, enterprises have increasingly stringent requirements for water quality stability, project implementation efficiency, space utilization, and operation & maintenance costs. Relying on modular innovative technology, HAFE-FG Water Technologies has launched the All-Process All-Container Integrated Water Treatment Plant (abbreviated as AAIWTP). With standardized production, intelligent operation, and customized adaptability, it accurately meets the demands of the mid-to-high-end market. The quality of the produced water strictly complies with the World Health Organization (WHO) drinking water standards, providing efficient water purification and wastewater treatment solutions for scenarios such as high-end manufacturing, energy extraction, and island industrial bases.

I. Core Advantages of the Solution: Targeting Pain Points in Mid-to-High-End Industrial Scenarios

Through integrated design, AAIWTP specifically addresses the core challenges of mid-to-high-end industrial water purification and wastewater treatment projects, with the following key advantages:

Rapid Implementation to Shorten Production Cycle: All equipment is manufactured in a standardized manner in the factory, supporting both marine and land transportation. Only simple on-site installation and commissioning are required, with a total construction period of up to 3-6 months. This is over 60% shorter than the construction cycle of traditional water plants, helping industrial projects to be put into production and generate revenue quickly.

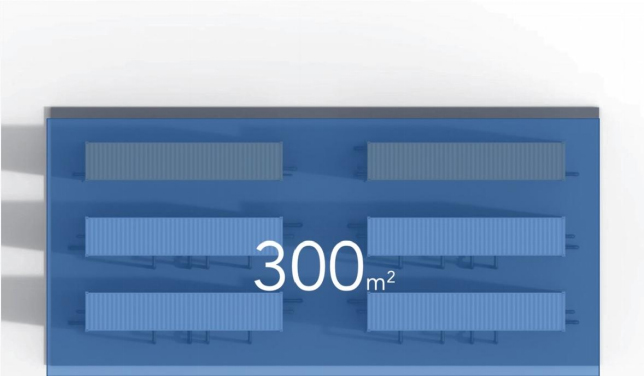

Extreme Space Saving for Tight Sites: Taking a treatment capacity of 10,000 tons per day as an example, it only covers an area of 300 square meters, which is 1/5 to 1/3 of the area required by traditional construction methods. It is perfectly suitable for mid-to-high-end industrial parks, coastal projects, and island projects where land resources are scarce.

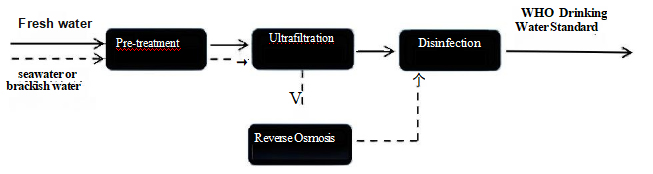

(Reverse Osmosis System Ultrafiltration Membrane Sys)Stable Quality to Meet Strict Standards: The full-process technology covers from pre-treatment to disinfection, ensuring that the quality of the produced water consistently meets WHO drinking water standards. It can satisfy the high-purity requirements for pure water in industries such as precision electronics, food processing, and pharmaceuticals.

II. Full-Process Treatment Technology: Building a Closed-Loop Water Quality Assurance System

AAIWTP integrates four core treatment units: pre-treatment, ultrafiltration, reverse osmosis (for brackish water/seawater scenarios), and disinfection, forming a complete water purification and wastewater treatment process. It can be flexibly adjusted according to the type of industrial raw water (freshwater/brackish water/seawater) to ensure stable and controllable water quality.

1. Pre-Treatment: Building a Protective Barrier for Membrane Systems

Aiming at large particulate impurities and organic matter in industrial raw water, the pre-treatment unit adopts a combined process of coagulation + air flotation + sedimentation + oxidation + self-cleaning filter. This effectively reduces the pollution risk of subsequent membrane systems and extends the service life of membranes. The unit is integrated into a standard high-cube container, with a coagulation zone, sedimentation zone, and regulating tank arranged from right to left. The hydraulic retention times are 10 minutes, 20 minutes, and 15 minutes respectively. The treatment capacity of a single container reaches 2500 m³/d, and the inner and outer walls are coated with anti-corrosion coatings, making it suitable for complex industrial water quality environments.

2. Ultrafiltration: Precisely Capturing Microorganisms and Suspended Solids

The exclusive Grapheilm2 ultrafiltration membrane module of HAFE-FG Water Technologies is adopted, with core advantages directly meeting industrial needs:

• Filtration precision reaches 0.02 μm, which can remove almost all particles, colloids, bacteria, and viruses. The turbidity of the produced water is ≤ 0.1 NTU, providing high-quality inlet water for the subsequent reverse osmosis system;

• The membrane material is PVDF (Polyvinylidene Fluoride) combined with patented graphene hydrophilic modification technology, featuring strong anti-pollution capability and adaptability to scenarios with fluctuating industrial raw water quality;

• The outside-in filtration method is adopted, which can withstand high suspended solid concentration in the inlet water, reduce cleaning frequency, and lower operation & maintenance costs.

Technical Parameters of Model P Ultrafiltration Membrane Rack: Membrane area is 51 m² per module; a single membrane rack contains 50-64 modules; the height of the membrane rack is 2150 mm, and the length is 9.0-10.5 m; the flow rate of a single membrane rack is 125 m³/h; the flow rate of a single module for freshwater is 2.5 m³/h, and for seawater is 2 m³/h. Different industrial projects can match the treatment scale by increasing or decreasing the number of membrane racks. For example, the GAAIWTPF-10000 model requires 200 ultrafiltration membrane modules, while the GAAIWTPS-10000 model requires 256 modules.

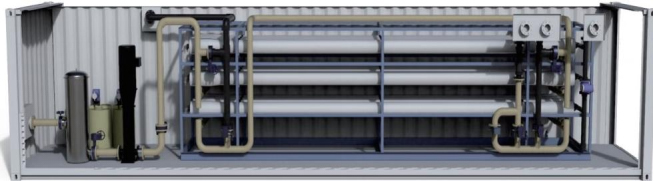

3. Reverse Osmosis: Efficient Desalination for Brackish Water/Seawater Scenarios

To meet the brackish water/seawater treatment needs in industrial scenarios such as coastal areas and mining areas, AAIWTP is equipped with a high-pressure-resistant reverse osmosis system:

• Core equipment is integrated into a membrane rack made of SUS316L material; the high-pressure pipeline is made of duplex 2205 stainless steel (corrosion-resistant and high-pressure-resistant), and the low-pressure pipeline is made of UPVC (Unplasticized Polyvinyl Chloride), making it suitable for harsh industrial environments;

• The size of a single container is 12000 mm × 2300 mm × 2900 mm, containing 30 reverse osmosis membrane vessels (pressure rating: 300-1000 PSI). Each membrane vessel is equipped with 6 membrane elements, and the total number of membrane elements in a single container is 180. The salt removal rate is as high as 99%, and a multi-stage system can further improve the desalination rate.

The parameters of commonly used seawater desalination reverse osmosis membrane elements are shown in the table below (Test conditions: operating pressure 800 psi (5.52 MPa), 32000 mg/L NaCl solution, 25°C, pH=8, recovery rate 8%):

| Model | Water Production Flow (GPD) | Water Production Flow (m³/d) |

|---|

| SW8040XHR-440 | 6600 | 25.0 |

| SW8040FR-400 | 8200 | 31.0 |

| SW8040HR-440 | 9000 | 34.0 |

| SW8040LE-440 | 9500 | 35.9 |

| Model | Rejection Rate (%) | Membrane Area (ft²) | Membrane Area (m²) |

|---|

| SW8040XHR-440 | 99.85 | 440 | 40.9 |

| SW8040FR-400 | 99.8 | 400 | 37.2 |

| SW8040HR-440 | 99.8 | 440 | 40.9 |

| SW8040LE-440 | 99.8 | 440 | 40.9 |

Operating Limits: Maximum operating pressure 1200 psi (8.28 MPa), maximum raw water flow 75 GMP (17 m³/h), maximum temperature 45°C, maximum raw water SDI₁₅ (Silt Density Index) 5, maximum free chlorine concentration < 0.1 mg/L, maximum pressure drop per membrane element 15 psi (0.1 MPa), pH range for chemical cleaning 1-13, pH range for raw water during operation 2-11.

4. Disinfection: Ensuring the Safety of End Water Quality

As the final link in the treatment process, precise addition of disinfectants not only ensures that there are no pathogenic microorganisms in the produced water but also inhibits the secondary growth of bacteria and viruses in industrial water supply pipelines. It is suitable for industries with extremely high requirements for water quality safety, such as food and pharmaceuticals.

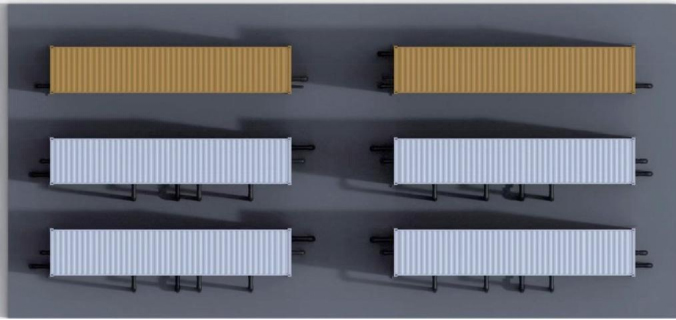

III. Flexible Model Configuration: Matching Diverse Needs of Mid-to-High-End Industry

AAIWTP takes a 40-foot standard container (12.0 m × 2.4 m × 2.4 m) as the basic unit, and is divided into Series F (for freshwater treatment) and Series S (for seawater treatment) according to the type of raw water. The number and functions of containers can be flexibly adjusted according to project scale and water quality characteristics (such as adding a raw water supply system, clean water tank, or dedicated treatment process for unconventional pollutants).

| Model | Pre-treatment | Ultrafiltration | Dosing System | Auxiliary System | Total | Daily Treatment Capacity |

|---|

| GAAIWTPF-2500 | 1 | 1 | 1 | 1 | 4 | 2500 tons |

| GAAIWTPF-5000 | 2 | 2 | 1 | 1 | 6 | 5000 tons |

| GAAIWTPF-7500 | 3 | 3 | 1 | 3 | 10 | 7500 tons |

| GAAIWTPF-10000 | 4 | 4 | 1 | 3 | 12 | 10000 tons |

| GAAIWTPF-15000 | 6 | 6 | 1 | 3 | 16 | 15000 tons |

| GAAIWTPF-20000 | 8 | 8 | 1 | 3 | 20 | 20000 tons |

| GAAIWTPF-25000 | 10 | 10 | 1 | 3 | 24 | 25000 tons |

| GAAIWTPF-30000 | 12 | 12 | 1 | 5 | 30 | 30000 tons |

| Model | Pre-treatment | Ultrafiltration | Reverse Osmosis System | Dosing System |

|---|

| GAAIWTPS-2500 | 1 | 1 | 1 | 1 |

| GAAIWTPS-5000 | 2 | 2 | 2 | 1 |

| GAAIWTPS-7500 | 3 | 3 | 3 | 1 |

| GAAIWTPS-10000 | 4 | 4 | 4 | 1 |

| GAAIWTPS-15000 | 6 | 6 | 6 | 1 |

| GAAIWTPS-20000 | 8 | 8 | 8 | 1 |

| GAAIWTPS-25000 | 10 | 10 | 10 | 1 |

| GAAIWTPS-30000 | 12 | 12 | 12 | 2 |

| Model | Auxiliary System | Total | Daily Treatment Capacity |

|---|

| GAAIWTPS-2500 | 1 | 5 | 2500 tons |

| GAAIWTPS-5000 | 1 | 8 | 5000 tons |

| GAAIWTPS-7500 | 1 | 10 | 7500 tons |

| GAAIWTPS-10000 | 2 | 15 | 10000 tons |

| GAAIWTPS-15000 | 3 | 22 | 15000 tons |

| GAAIWTPS-20000 | 4 | 29 | 20000 tons |

| GAAIWTPS-25000 | 4 | 35 | 25000 tons |

| GAAIWTPS-30000 | 5 | 43 | 30000 tons |

IV. System Layout and Intelligent Operation: Reducing Costs and Increasing Efficiency to Adapt to Mid-to-High-End O&M Standards

1. Compact Layout for Optimal Space Utilization

AAIWTP adopts a double-layer container layout design, further reducing the occupied area through vertical space utilization. The estimated occupied area of each model is shown in the table below, and its space utilization is far superior to that of traditional water plants:

| Model | Number of Containers | Occupied Area (m²) |

|---|

| GAAIWTPF-2500 | 3 | 80 |

| GAAIWTPF-5000 | 5 | 100 |

| GAAIWTPF-7500 | 7 | 210 |

| GAAIWTPF-10000 | 12 | 300 |

| GAAIWTPF-15000 | 15 | 400 |

| GAAIWTPF-20000 | 20 | 500 |

| GAAIWTPF-25000 | 24 | 600 |

| GAAIWTPF-30000 | 29 | 700 |

| Model | Number of Containers | Occupied Area (m²) |

|---|

| GAAIWTPS-2500 | 5 | 100 |

| GAAIWTPS-5000 | 8 | 240 |

| GAAIWTPS-7500 | 12 | 300 |

| GAAIWTPS-10000 | 15 | 400 |

| GAAIWTPS-15000 | 22 | 550 |

| GAAIWTPS-20000 | 29 | 700 |

| GAAIWTPS-25000 | 35 | 800 |

| GAAIWTPS-30000 | 43 | 1100 |

2. Intelligent Operation to Reduce O&M Costs

Through fully automated and remote monitoring design, AAIWTP significantly reduces the O&M difficulty and costs of mid-to-high-end industrial projects:

• 100% Fully Automated Operation: All models do not require daily manual maintenance, and only need manual intervention when chemicals are insufficient or equipment malfunctions, reducing labor input and operational errors;

• Remote SCADA System: Operational parameters (such as water production volume, water quality indicators, and energy consumption) can be obtained in real-time through a remote PC or smartphone, supporting remote adjustment; users can customize data reports, and the system automatically sends and stores data in the local cloud, facilitating compliance management and data analysis;

• Transparent Operation Costs: Costs only include electricity fees (estimated at 0.1 USD/kWh) and chemical fees, excluding labor costs: freshwater treatment costs approximately 0.015 USD/m³ (0.1 CNY/ton of water), and seawater treatment costs 0.5-0.8 USD/m³ (4-6 CNY/ton of water), with strong cost controllability.

V. Application Scenarios of the Solution: Focusing on Core Needs of Mid-to-High-End Industry

With its compact, efficient, and intelligent features, AAIWTP can be widely applied in water purification and wastewater treatment scenarios in the mid-to-high-end industrial field:

• High-End Manufacturing Parks: Providing high-purity production water for industries such as electronics, semiconductors, and precision machinery to meet the strict water quality requirements for product quality;

• Coastal Energy Bases: Treating seawater or brackish water to provide stable industrial water for energy projects such as petrochemicals and nuclear power, solving the problem of freshwater scarcity in coastal areas;

• Island Industrial Projects: Adapting to the characteristics of tight land and scarce freshwater on islands, providing water quality assurance for island tourism development, marine engineering, and other projects;

• Emergency Industrial Support: It can be quickly deployed to sudden water pollution incidents or temporary industrial projects, and put into production within 3-6 months to ensure the continuity of industrial production.

Centered on "standardized modules + customized design", HAFE-FG Water Technologies' AAIWTP redefines the mid-to-high-end industrial water purification and wastewater treatment model. It not only meets strict water quality and efficiency requirements but also helps enterprises save space, time, and O&M costs, making it the preferred solution for mid-to-high-end industrial water purification and wastewater treatment.

For custom requirements, please contact us:

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:All-Process All-Container Integrated Water Treatment Plant