Instructions for MBR - AO Underground Integrated Biochemical Sewage Treatment Equipment

1. Overview

The MBR - AO integrated sewage treatment technology is an efficient biochemical water treatment technology that combines biotechnology and membrane technology. It is an efficient sewage treatment technology that integrates biofilm and traditional activated sludge method. Due to the filtration effect of the biofilm, microorganisms are retained in the bioreactor, realizing the complete separation of hydraulic retention time and sludge age, and maintaining a high MLSS (Mixed Liquor Suspended Solids) in the bioreactor. It has strong nitrification capacity and high pollutant removal rate.

The application of MBR membrane treatment replaces the secondary sedimentation tank in the activated sludge method for solid - liquid separation, effectively achieving the purpose of sludge - water separation. By making full use of the efficient interception function of the biofilm, nitrifying bacteria can be effectively intercepted and completely retained in the bioreactor, ensuring the smooth progress of the nitrification reaction, effectively removing ammonia nitrogen, avoiding the loss of sludge, and also intercepting macromolecular organic substances that are difficult to degrade temporarily, extending their residence time in the reactor to achieve maximum decomposition. After applying the integrated sewage treatment technology, the removal rate of major pollutants can reach: COD ≥ 93%, SS = 99%. The suspended solids and turbidity in the effluent are almost zero, and the treated water quality is good and stable, realizing the recycling of sewage.

2. Advantages

The MBR - AO integrated equipment is an integrated equipment that uses biological film formation for sewage treatment and reuse. It has all the advantages of membrane bioreactors: good effluent quality, low operating cost, strong system impact resistance, small amount of sludge, and high degree of automation. In addition, as an integrated equipment, it occupies a small area and is easy to integrate. It can be used as a small - scale sewage reuse equipment or as the core treatment unit of a larger - scale sewage treatment plant. It is one of the research hotspots in the field of sewage treatment at present and has broad application prospects.

3. Application Fields

It is suitable for domestic sewage from residential quarters, office buildings, shopping malls, hotels, restaurants, government agencies, schools, military units and other places, as well as similar industrial organic wastewater, such as organic sewage treatment in industries such as textiles, beer, papermaking, leather making, food, machinery, breeding, slaughtering, and chemical industry.

4. Effluent Quality of MBR - AO Integrated Equipment for Domestic Sewage Treatment (for Reference Only)

Category | Raw Water Quality (mg/L) | Treated Water Quality (mg/L) | National First - level Discharge Standard (GB18918 - 2002) | Domestic Reclaimed Water Quality Standard (CJ25.1 - 89) | Domestic Reclaimed Water Quality Standard (CJ25.1 - 89) |

|

|

|

| Toilet Flushing, Greening | Car Washing, Cleaning |

BOD (mg/L) | 150 - 250 | < 10 | 20 | 10 | 10 |

COD (mg/L) | 200 - 400 | < 50 | 60 | 50 | 50 |

SS (mg/L) | 150 - 250 | < 10 | 20 | 10 | 5 |

Ammonia Nitrogen (mg/L) | 10 - 35 | < 5 | (8) 15 | 20 | 10 |

Note: This equipment can be customized according to customer requirements.

5. Process Characteristics

• Good Effluent Quality: The advanced membrane bioreactor technology is adopted, so that the effluent quality of the system is better than that of traditional sewage treatment equipment in all aspects. The effluent quality is close to that of tap water in terms of sense and can be used as reclaimed water for reuse.

• Small Occupied Area: Due to the efficient separation effect of the membrane, there is no need to set up solid - liquid separation equipment such as sedimentation and filtration, no backwashing is required, and the concentration of suspended solids in the effluent is much lower than that of traditional solid - liquid separation equipment. This makes the entire system process simple, easy to integrate, and the occupied area of the system is greatly reduced.

• Reduced Operating Costs: The membrane bioreactor can filter out harmful substances such as bacteria and viruses, which can reduce the disinfection device and daily dosage, making management and operation more convenient.

• Strong System Impact Resistance and Wide Adaptability: It prevents the loss of various microbial communities, which is beneficial to the growth of bacteria with slow reproduction speed (such as nitrifying bacteria), and prolongs the residence time of some macromolecular refractory organic substances, which is conducive to their decomposition, so that various metabolic processes in the system can proceed smoothly.

• High Degree of Automation: Due to the adoption of membrane technology, the MBR - AO greatly shortens the process flow. Through advanced control technology, the equipment is highly integrated and intelligent, and it is one of the reclaimed water reuse equipment with a high degree of automation in China so far.

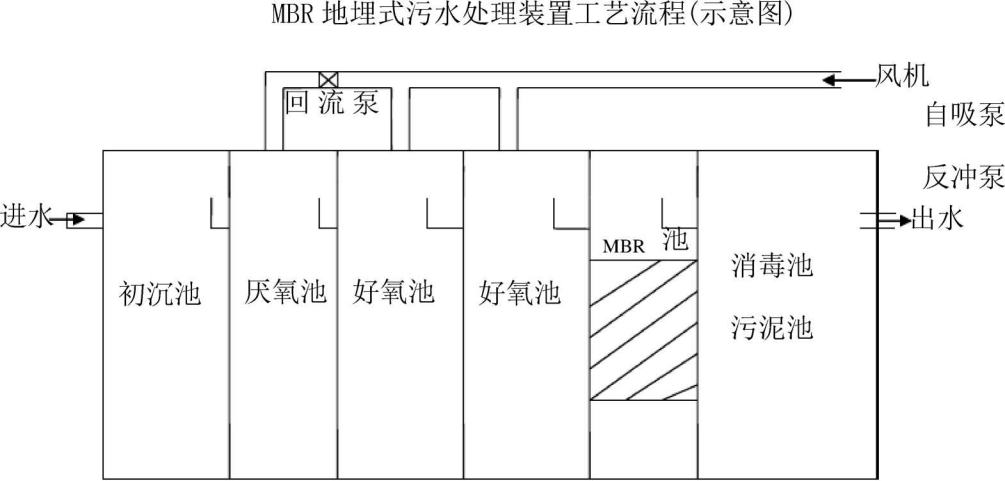

6. Process Flow of Underground Sewage Treatment Device (the Product Shall Be Based on the Actual One)

The above diagram is for reference only, and the specific design shall be based on the actual situation.

Explanation of the Process Flow

Production wastewater passes through a mechanical grid (optional, this equipment is installed separately if needed) to remove large floating objects and suspended solids, and then enters the regulating tank. The wastewater in the regulating tank is pumped to the primary sedimentation tank, and then flows into the hydrolysis acidification tank by gravity. In the hydrolysis acidification tank, macromolecular organic substances are decomposed into small molecular organic substances, and insoluble organic substances are converted into soluble organic substances. When entering the aerobic tank, the biodegradability of the sewage is improved, and the oxygen utilization efficiency is enhanced.

The water from the acidification tank flows into the aerobic aeration tank by gravity. The biochemical tank is equipped with hollow fiber fillers, which have good elasticity and corrosion resistance, and are suitable for the needs of microbial film formation. The biochemical tank can be equipped with a first - stage biochemical tank, a second - stage biochemical tank, or even a multi - stage biochemical tank according to needs. The water from the biochemical tank flows into the MBR membrane tank by gravity. At this time, the sewage completes the sludge - water separation in the MBR membrane tank. The effluent enters the clear water tank (if disinfection is needed, the user can carry out disinfection treatment in this unit), and the sludge enters the sludge tank. A part of the sludge can be returned to the acidification tank or aerobic tank according to needs, or can be pumped out. The blower, self - priming pump, and backwash pump are generally outside the equipment.

Note: Picture source: Original document "Instructions for MBR Underground Domestic Sewage Treatment Equipment"

7. Main Technical Parameters

Main Technical Parameters (for Reference Only, Customizable)

Model/Item | WSZ 0.5 | WSZ 0.5 | WSZ 1 | WSZ 1 | WSZ 3 | WSZ 3 | WSZ 5 | WSZ 10 | WSZ 10 | WSZ 20 | WSZ 20 | WSZ 30 |

Treatment Capacity (m³/h) | 0.5 | 0.5 | 1 | 1 | 3 | 3 | 5 | 10 | 10 | 20 | 20 | 30 |

Blower - Model | HB - 0.75 | HB - 0.75 | HB - 0.75 | HB - 0.75 | HB - 1.1 | HB - 1.1 | HB - 2.2 | HB - 4.4 | HB - 4.4 | HB - 8.8 | HB - 8.8 | HB - 11.5 |

Blower - Power (KW) | 0.75 | 0.75 | 0.75 | 0.75 | 1.1 | 1.1 | 1.2 | 4.4 | 4.4 | 4.4×2 | 4.4×2 | 11.5 |

Water Pump - Model | 40QW7 - 10 - 0.75 | 40QW7 - 10 - 0.75 | 40QW7 - 10 - 0.75 | 40QW7 - 10 - 0.75 | 40QW10 - 7 - 0.75 | 40QW10 - 7 - 0.75 | 40QW10 - 7 - 0.75 | 50QW10 - 10 - 1.1 | 50QW10 - 10 - 1.1 | 50QW25 - 7 - 1.5 | 50QW25 - 7 - 1.5 | 50QW42 - 9 - 2.2 |

Water Pump - Power (KW) | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 0.75 - 1.1 | 1.5 | 1.5 | 2.2 |

Inlet Water - BOD5 (mg/L) | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 | 150 - 400 |

Effluent - BOD5 (mg/L) | - | - | - | - | - | - | - | - | - | - | - | - |

Occupied Area (m²) | 4.5 | 6.5 | 6.5 | 12 | 12 | 15 | 15 | 35 | 51 | 51 | 76 | 76 |

8. The Advantages of MBR - AO Integrated Equipment Are Mainly Reflected in the Following Aspects

1. It has a high removal rate of pollutants, strong resistance to sludge bulking, stable and reliable effluent quality, and almost no suspended solids in the effluent.

2. It has a high degree of automation, which can realize the conversion between automatic and manual control. The operation is simple, the management is convenient, the effluent quality is stable and can be directly reused. The amount of sludge is small, which reduces the cost of excess sludge treatment.

3. The process flow is simple, the structure is compact, and under high volume load, the residence time is short and the occupied area is small.

4. It can remove organic substances and ammonia nitrogen, and improve the load impact resistance of the system.

5. The operation cost is low, and there is no secondary pollution.

6. It can be buried underground according to the site arrangement, and parking or greening can be done on it, which greatly reduces the investment.

(Note: The above instructions are a general version, and the specific data shall be based on the actual situation.)

9. Equipment Maintenance

A regular maintenance system should be established for the integrated domestic sewage treatment equipment. The main vulnerable parts are the blower and the water pump.

Regularly check the tightness of the screws of various parts of the blower and the water pump, the tightness of the packing box, the temperature of the bearings, and the quality and quantity of the lubricating oil to ensure that all parts are in normal condition. The blower and the water pump must be maintained and repaired every 5000 - 8000 hours of operation.

10. Operation Process and Common Fault Inspection

Operation Process

1. Start the lift pump. If it fails to start normally, check whether the float is working properly.

2. Start the aeration blower and check the oil level regularly to see if there is a lack of oil.

3. Regularly check whether the aeration volume is normal.

(II) Common Fault Inspection

1. Abnormal Effluent:

Check whether the connecting pipes of the anaerobic tank, aerobic tank, sludge tank, and clear water tank are blocked (the blockage is generally the fallen biofilm).

2. Uneven Aeration in the Contact Oxidation Tank:

Check whether the outlet valve of the aeration blower is in the normal position and whether the aeration head is damaged.

3. Unobvious Contact Effect of Biological Film Formation:

Check whether the aeration in the contact oxidation tank is uniform. If the above situation is normal, add an appropriate amount of nutrients (sugar, urea, etc.) to the tank.

4. Effluent Quality Not Meeting the Standard:

• The inlet water volume is too large.

• The aeration in the contact oxidation tank is uneven or the tank is out of service for a long time (in this case, the biofilm must be re - cultivated).

• There is too much sludge in the sedimentation tank (the sludge must be completely removed).

• Check whether the supporting lift pump and aeration blower are damaged (in this case, the current may be too large, and the short - circuit switch will automatically disconnect).

(Note: The above instructions are a general version, and the specific data shall be based on the actual situation.)

Cultivation Method and Precautions of MBR Membrane Underground Biological Bacteria

The bacterial species are the activated sludge from the sewage treatment plant, and the added amount is about 1/5 of the total volume of the equipment. Before adding, the anaerobic tank and the aerobic tank should be filled with no less than 2/3 of sewage (if clear water is added, a small amount of urea should be added to supplement ammonia nitrogen), and the blower should be turned on. When adding the sludge, the blower should be kept on. (Generally, after carefully removing the outer packaging plastic bag of the MBR membrane, first add clear water to the MBR membrane tank until it submerges the MBR membrane at least, then add sewage to the anaerobic tank and the aerobic tank, turn on the blower, adjust the aeration in the aerobic tank and the MBR membrane tank to be uniform through the PVC ball valve of the MBR membrane tank, and then add the sludge.)

The biological bacteria cultivation requires that the water pH is between 6 and 9, and the temperature is between 0 and 30 degrees. If the activated sludge fails to dissolve in time when added, wait for a few minutes and add it again. Note that when adding sludge to the MBR membrane tank, do not hit the membrane, and the added amount should not be too much. The method for determining the amount of sludge added: turn on the blower, take a bottle of sewage from the aerobic tank, let it settle, and check the proportion of the sludge. Generally, it should be between 1/5 and 1/4.

During the sludge cultivation, it is required to add a small amount of sewage every two days. Therefore, the liquid level lines of the regulating tank and the MBR membrane tank can be removed and connected again after the biological bacteria are cultivated. (Disconnect the wire of the sludge return pump) and reconnect it after the biological bacteria are cultivated.

After adding the sludge, set the electric control box to the automatic mode. The blower will operate intermittently automatically according to the time set by the time relay. Cultivate continuously for 3 - 5 days (in cold areas such as the three northeastern provinces and Inner Mongolia, it usually takes 5 - 7 days), and observe the color change of the sludge. Generally, the best color is tawny or grayish brown, and a large amount of sludge is attached to the elastic filler.

After 3 - 5 days of continuous cultivation, add a small amount of sewage to the equipment every two days, and the amount of sewage added each time is slightly more than that of the previous time. Aerate for two days / add a small amount of sewage / aerate for another two days / add a small amount of sewage again... and so on for about 20 days to one month (it usually takes 2 - 3 months in cold weather). The biological bacteria will be cultivated well depending on the specific situation. Note that during the cultivation of biological bacteria, the sewage in the MBR membrane tank should be discharged in time (manually turn on the drainage pump to drain water), and the water level after discharge should not be lower than the MBR membrane.

After the biological bacteria are cultivated, set the time of the time relay in the electric control box, adjust the liquid level line, set the electric control box to the automatic state, and the equipment will operate automatically without the need for special personnel to manage it.

The waterproof maintenance of various motors and electric control boxes of the equipment and the thermal insulation of the pipelines shall be handled by yourself.

If the equipment does not treat sewage for a long time (usually during holidays) for more than one month, add a small amount (must be a small amount) of urea or starch to the anaerobic tank and aerobic tank of the equipment every week to supplement ammonia nitrogen. In addition, the electric control box of the equipment shall not be powered off and shall be kept in the automatic state all the time.

Setting of the Time Relay in the Electric Control Box

1. The blower operates for 60 minutes and pauses for 15 minutes.

2. The sludge return valve of the sludge return pump is opened once a month to pump sludge into the sludge tank for 2 minutes. When the sludge tank is full of sludge, pump the sludge out of the tank.

High and Low Pressure Range of the Electric Contact Pressure Gauge

• 0.02 — — 0.08 Mp