Desalt R Sea Water Reverse Osmosis (SWRO)

Desalt R series Sea Water Reverse Osmosis (SWRO) machine is a small all-in-1 system, with most parts installed in 1 skid.

It is suitable for municipal use of small island, hotel, warship and other high-reliability applications. The fresh water capacity is 270 to 1,080 liter/hour (1.2-4.8 USgpm).

1 Description

iDesalt R series watermaker is designed to produce high quality portable water from sea water or high salinity brackish water. R series watermaker produce pure potable water from 6,000 to 55,000 litres (1,600-14,500 gallon) per day.

Together with 2 pass RO system and EDI system provided by QT, the watermaker could make ultra-pure water, which is used for chemistry, pharmaceutical or electronic industries. For more details, please contact us.

iDesalt R series watermaker is a small desalination system based on reverse osmosis principle which is the most popular water treatment technology in the world.

2 type is available for iDesalt R series:

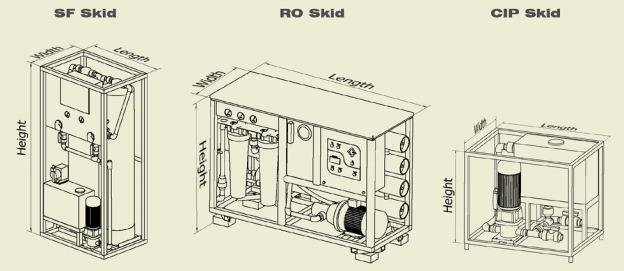

Modular: using R-xx(xx is normally the capacity of the system) as type name. The pretreatment unit (which is normally sand filter here), SWRO unit and chemical clean unit are designed as separated skids. It will be more flexible to choose modular design when the entrance or the space is limited, or there is no crane available.

All-in-1: using R-xxA as type name. The pretreatment unit, SWRO unit and chemical clean unit are carefully designed to be put into 1 skid. All-in-1 design could save installation time on site.

Note: The image shown here is indicative only. The actual product may differ.

R series watermaker is user friendly and could be operated and maintained like a washing machine. Cage design protects the watermaker from damage during operating and transportation.

To ensure the reliability of the watermaker, the core parts from the well-known manufacturers in water treatment area, such as Danfoss, Pentair, Dow, Wika, Toray, Schneider, etc. are adopted and the system is optimized with experienced engineers who have more than 20-year experience.

iDesalt watermaker are designed and manufactured on the basis of the industrial standard: ASME, ASTM, IEC, etc.

iDesalt R series watermaker is CE approved.

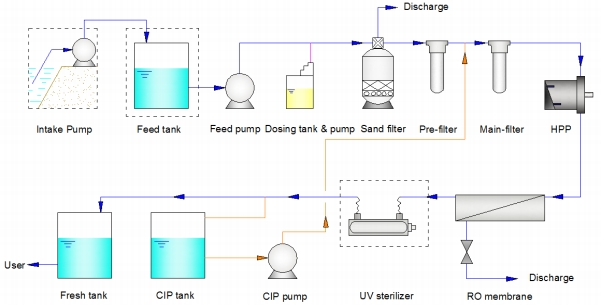

2 Process

The seawater is taken by an intake pump and sent to a feed tank (if seawater is taken from a very close place and the water turbidity is quite low, seawater could be sent directly to the Watermaker). Seawater from feed tank is boosted by feed pump and is sent to sand filter to remove particles. After too pass cartridge filter, seawater is pressurized by high pressure pump and sent to membrane. Thus we got fresh water, while the same time the concentrated water is discharged directly. Please refer the following process flow diagram for more details.

Note: the equipment marked by dashed box are optional.

3 Features

Modular design increase the flexibility for application and installation, eg. Really good feed water could save pretreatment unit.

All-in-1 design minimize the site installation.

Simple process, feed pump is used as backwash pump for sand filter.

Absolute filter element ensure the safe operation of high pressure pump and RO membrane. Super duplex high pressure pump using axial piston principle from Danfoss, higher efficient,

lighter, more compact than common plunger pump, and the service life is up to 3 year.

High pressure hose lower the vibration and noise level, simplify the pipe connection. Non-welding duplex pipe and fittings, long life and highly corrosion resistant.

High salt rejection RO membrane from Toray, low fouling technology.

SS304 frame with 3 layers of paint avoid the corrosion from salt fog and leaking.

“Cage design” protects the watermaker from damage during operation and transportation. User friendly, operated and maintained like a washing machine, could add biocides(non-oxidative biocides) to keep the membrane at good condition.

IP54 protection level for control panel, and using Schneider or Omron parts to ensure the reliability of the control system.

CIP pump is used as a spare pump for feed pump.

Optional UV kit (Ultraviolet sterilizer), which ensure the safety of the product water.

Optional SF auto kit, which could regenerate SF automatically.

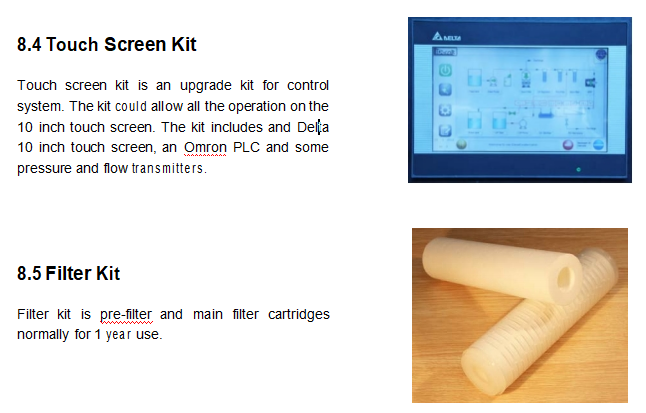

Optional touch screen system, which is more user friendly.

Optional ERD (energy recovery device) kit, which could save energy consumption up to 45%.

4 Application

Island residential, remote coast area.

Hotels, resorts.

Fishing boat, yacht.

Cruise ships, warships, public service vessels. Lighthouse.

Offshore oil rigs

High salinity underground water

5 Specification

5.1 Feed water requirement

Salinity (TDS) | 20,000-45,000 mg/L |

Temperature | 5-40 °C |

Turbidity | < 5 NTU |

COD | < 10 mg/L |

Ferrous (Fe2+) | < 0.1 mg/L |

Manganese (Mn2+) | < 0.1 mg/L |

Note: if the feed water is worse than above, extra pretreatment might be needed. Please contact us for solutions. |

5.2 Product water quality

Standard 1) | acceptable drinking water quality for WHO (2012) |

Conductivity (online monitoring) 2) | < 1000 μS/cm |

Note: 1) If the source water is natural seawater (or salt water). 2) If the water is for clean or irrigating, higher conductivity might be acceptable. |

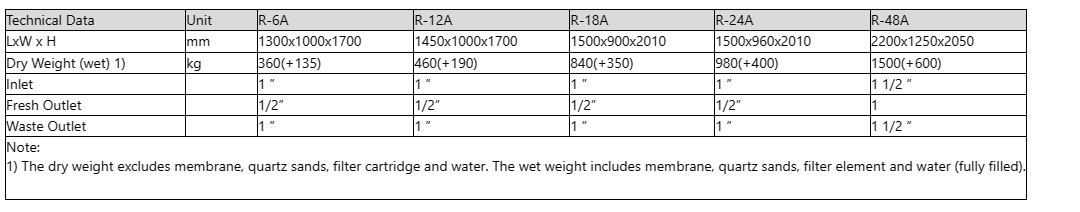

5.3 Technical Data

Technical Data | Unit | R-6(A) | R-12(A) | R-18(A) | R-24(A) | R-48(A) |

Rated Product Flow 1) | L/H GPH | 300 80 | 550 150 | 850 220 | 1100 290 | 2300 610 |

Rated Recovery Rate 1) | % | 30 | 34 | 34 | 34 | 34 |

Min. Feed-in Pressure | barg | 0 | 0 | 0 | 0 | 0 |

Max. Feed-in Pressure | barg | 2 | 2 | 2 | 2 | 2 |

Min System Pressure 2) | barg | 20 | 20 | 20 | 20 | 20 |

Max System Pressure | barg | 70 | 70 | 70 | 70 | 70 |

RO Membrane Spec. | inch | 4040 | 4040 | 4040 | 4040 | 8040 |

RO Membrane Qty. | pcs | 2 | 4 | 6 | 8 | 4 |

Power |

Rated Power 3) | kW | 3.8 | 5.2 | 7.7 | 10.2 | 18.5 |

Input 4) |

| 3PH, 380 AC±10%, 50Hz |

Note: 1) The rated product flow and rated recovery rate are based on the design feed (35,000 ppm, 20°C standard seawater). If the feed TDS is lower, higher product flow and higher recovery rate could be available; If the feed TDS is higher, product flow and recovery rate might be lower to avoid over pressure or scaling, contact us for details. 2) The normal system operating pressure shall be above the minimum pressure, and shall not exceed the maximum pressure. For higher system pressure, please contact us. 3) The maximum power at 70bar. 4) For other input voltage and frequency, please inform us while placing the order. |

Note: The image shown here is indicative only. The actual product may differ.

Technical Data | Unit | R-6 | R-12 | R-18 | R-24 | R-48 |

SF Skid, L x W x H | mm | 660x650x1540 | 860x650x1540 | 990x710x2000 | 1090x760x2000 | 1290x850x2000 |

SF Skid Dry Weight (wet) | kg | 160(+80) | 280(+120) | 520(+220) | 700(+260) | 890(+350) |

Feed Inlet |

| 1 ” | 1 ” | 1 1/4 ” | 1 1/4 ” | 1 1/2 ” |

Filtrate Outlet |

| 1/2” | 1 ” | 1 1/4 ” | 1 1/4 ” | 1 1/2 ” |

Waste Outlet |

| 1 ” | 1 ” | 1 1/4 ” | 1 1/4 ” | 1 1/2 ” |

RO Skid, L x W x H | mm | 1410x470x940 | 1600x600x1020 | 1600x760x1020 | 1600x760x1020 | 1750x830x1550 |

RO Skid Dry Weight (wet) 1) | kg | 160(+15) | 310(+30) | 350(+50) | 420(+60) | 700(+100) |

Feed Inlet |

| 1/2” | 1 ” | 1 ” | 1 1/4 ” | 1 1/2 ” |

Product Outlet |

| 1/2” | 1/2” | 1/2” | 3/4” | 1 ” |

Concentrate Outlet |

| 1/2” | 1/2” | 1/2” | 1/2” | 1 ” |

CIP Forward (RO) |

| 1/2” | 1/2” | 3/4” | 3/4” | 1 1/4 ” |

CIP Backward (RO) |

| 1/2” | 1/2” | 3/4” | 3/4” | 1 1/4 ” |

CIP Skid, L x W x H | mm | 600x500x630 | 600x500x630 | 700x400x1000 | 700x400x900 | 850x620x1000 |

CIP Skid Dry Weight (wet) | kg | 30(+40) | 30(+40) | 50(+80) | 50(+80) | 65(+150) |

CIP Forward |

| 1/2” | 1/2” | 3/4” | 3/4” | 1 1/4 ” |

CIP Backward |

| 1/2” | 1/2” | 3/4” | 3/4” | 1 1/4 ” |

Drain |

| 1/2” | 1/2” | 3/4” | 3/4” | 1 1/4 ” |

Note: 1) The dry weight excludes membrane, quartz sands, filter cartridge and water. The wet weight includes membrane, quartz sands, filter element and water (fully filled). |

5.4 Dimensions and weight

R series size

Note: The image shown here is indicative only. The actual product may differ.

6 Installation

6.1 Water Intake

iDesalt R series watermaker is designed for taking clean seawater or brackish water.

If possible, beach well intake or buried perforated pipe intake is preferred to acquire better source water.

If there are a lot of sands or silts in the source water from open intake, enhanced pretreatment like clarifier or slow sand filter is strongly recommended. Otherwise, the life of filter cartridge and regeneration period of sand filter will be shortened.

A dosing unit is equipped on R series. Dosing coagulant like FeCl3 or PAC might be another choice if the feed turbidity is high.

For more intake details, please contact us.

If the water is from open intake (water taken directly from sea), a feed tank is recommended. Feed tank would help to settle the sands down and provide a buffer of feed water. If there is a feed tank, a low level switch shall be installed to avoid dry-running of the feed pump.

Submersible pump or jet pump (self-priming pump) made from plastic, SS316L or better is recommended as intake pump.

For long distance water transportation, a boost pump might be needed to provide enough flow. HDPE pipe is recommended for long distance water supply.

6.2 Watermaker

Sand filter

3 step filtering is used in iDesalt R series.

The first step is sand filter. The sand filter remove most of particles above 100 micron.

The sand filter shall be regenerated periodically to recover its performance. The period is depending on the feed water turbidity. Normally we recommend regenerating the sand filter every 7 days or the ΔP is over 0.8 bar.

The feed water from feed tank or intake pump is boosted by feed pump and then sent to sand filter. The feed pump is also used as the backwash pump of sand filter.

Normally the quartz sands are not filled to avoid the possible damage during transportation. Fill the sands before commissioning.

Cartridge filter

The second step is pre-filter. 3 micron nominal deep filtering cartridge(s) (melt-blown cartridges, 85%) or better is installed to remove the particles passed sand filter.

The third step is main filter. 10 micron absolute cartridge(s) (pleated cartridges, 99.9%) or better is installed to ensure the safety operating of high pressure pump and RO membrane.

Using the right filter cartridges is the key to keep the high pressure pump and RO membrane running well.

Installed the filter cartridges before the system is started.

Note: QT recommends strongly to use the original service kit from QT.

RO

The filtered water is pressurized to 50-60 bar and sent to RO membrane by an axial piston pump. The high pressure pump is positive displacement pump, therefore, the feed flow is constant while

operating. The generated pressure depends on the feed salinity and temperature.

To avoid membrane damage, ΔP between permeate side and feed side shall never exceed 0.5 bar.

The membranes are not installed to avoid drying or bio-fouling due to long time transportation and site construction.

Install the membranes before the system is started.

The product flow and recovery rate of the system could be adjusted by the pressure adjusting valve on the concentrate pipeline. For the watermaker with ERD kit, the recovery rate is fixed and the flow could be adjusted by change the frequency of VFD.

CIP

CIP pump is used as flushing pump and chemical cleaning pump, and is also a spare pump for feed pump. When the feed pump is out of work, replace it with the CIP pump for a temporary solution.

6.3 Water tank

If there is a feed tank, at least a low level switch shall be installed to avoid the dry running of the feed pump.

Install a high level switch and low level switch on the product tank and connect them to the control cabinet, then you could run the system automatically according to water level, i.e. automatically ON when low level trigger, automatically OFF when high level trigger.

If the product tank is very large, keep the water in the tank away from sunshine, add some calcium hypochlorite or sodium hypochlorite if the water is kept for a time longer than 3 days.

If the product tank is an elevated tank, install a non-return valve on the fresh water pipeline to avoid higher back pressure on the membrane.

7 Storage, Service and Warranty

7.1 Storage

iDesalt R series are designed for indoor use. The units should be put or stored on a flat, dry and well ventilated place if possible.

Ambient temperature during operating: +2°C to +50°C

Storage temperature: -5°C to +60°C – provided that:

The system is drained of water ;

The system is stored “plugged”;

The membranes and filter cartridges are taken out and stored separately.

Do not install membranes and filter cartridges until the system will be started.

Note: The RO membranes should be stored in a dry and well ventilated place without sunshine, and the storage temperature is: 5-35 °C.

7.2 Maintenance

Good maintenance prolong the system life.

For short term stop

After the system is stopped, the CIP pump will automatically flush the RO system with product water. Cleaning chemical or biocides could be added in the CIP tank, the system will maintain the RO

membrane automatically after stop.

Note: ONLY NON-OXIDATIVE biocides (like NaOH, Na4EDTA, DBNPA, etc.) could be added, otherwise the RO membrane will be damaged.

Normally for short term stop like less than 3 days, it will be OK for the system with NO flushing.

For long term stop

If the system will be standstill for more than 3 days, the system shall be started for 15min every 3 days, and flushed with RO product water. The sand filter shall be backwashed at the same time.

If the system will be standstill for more than 3 months, the system shall be flushed with RO product water (with reserving chemical inside) thoroughly. And the system shall be started for short time every 7-10 days, and flushed with RO product water (with reserving chemical inside). The sand filter shall be backwashed at the same time to avoid biofouling.

If the system will be standstill for a long time, a chemical cleaning shall be done for membrane. Taking the membrane out and store the membrane separately in a reserving solution is recommended.

Routine maintenance

1. Regenerate the sand filter periodically, we recommend backwash and rinse sand filter every 7 days or ΔP between inlet and outlet is above 0.8 bar.

2. Change the filter cartridge periodically, we recommend a replacement every 30 days or ΔP between inlet and outlet is above 1 bar (1 bar for pre-filter and 1 bar for main filter).

Note: life of the cartridge in pre-filter may be shorter than the one in main filter.

Note: QT recommends putting 3 micron nominal filter cartridge (normally melt-blown cartridge, 85%) or better in pre-filter. QT recommends putting 10 micron absolute filter cartridge (normally pleated cartridge, 99.9%) or better in main filter.

3. Maintain the RO membrane with chemicals (like non-oxidative biocides or NaOH) periodically to keep the performance of membrane.

4. Regular cleaning to remove the dust or salty dirt from the system.

5. Online chemical cleaning, we recommend a chemical cleaning for membrane every 6 months. Look for the manual for how to clean the membrane.

Warning: Chemical cleaning must be done by authorized service staff or especially qualified and trained personnel.

7.3 Service

In case of irregular function of iDesalt, please contact QT.

7.4 Guarantee

Provided that the equipment has been running according to the QT’s specifications, QT provides 12 months guarantee from date of commissioning, however, max. 18 months from date of production.

8 Optional parts and ordering information

8.1 Intake pump

![1687139956602641.png {YA6G9K]JX589B6}]_L$VJS.png](/static/upload/image/20230619/1687139956602641.png)

8.7 Ordering information

Item | Type | Description | Code No | Manufacturer |

iDesalt R Series | R-6 | Modular design, cage protection | 101A003 | iDesalt |

R-12 | Modular design, cage protection | 101A004 | iDesalt |

R-18 | Modular design, cage protection | 101A006 | iDesalt |

R-24 | Modular design, cage protection | 101A007 | iDesalt |

R-48 | Modular design, cage protection | 101A009 | iDesalt |

R-6A | all-in-one design, cage protection | 102A003 | iDesalt |

R-12A | all-in-one design, cage protection | 102A004 | iDesalt |

R-18A | all-in-one design, cage protection | 102A006 | iDesalt |

R-24A | all-in-one design, cage protection | 102A007 | iDesalt |

R-48A | all-in-one design, cage protection | 102A009 | iDesalt |

Intake pump | Jet-35 | for R-6(A)/12(A), self-priming, SS316L | 111P003 | CNP |

Jet-45 | for R-18(A)/24(A), Self-priming, SS316L | 111P006 | CNP |

SP8A | for R-48(A), submersible, SS904L | 111P009 | Grundfos |

Feed pump | CDLF2-4 | for R-6(A), SS316L, 1PH 220V, 50Hz | 112P003 | CNP |

CDLF2-5 | for R-12(A), SS316L, 1PH 220V, 50Hz | 112P004 | CNP |

CDLF4-4 | for R-18(A), SS316L, 3PH 380V, 50Hz | 112P006 | CNP |

CDLF4-5 | for R-24(A), SS316L, 3PH 380V, 50Hz | 112P007 | CNP |

CDLF8-4 | for R-48(A), SS316L, 3PH 380V, 50Hz | 112P009 | CNP |

SF Auto kit |

| for R-6(A), automate SF | 113P003 | iDesalt |

| for R-12(A)/18(A), automate SF | 113P004 | iDesalt |

| for R-24(A)/48(A), automate SF | 113P007 | iDesalt |

ERD kit |

| for R-6(A), SS2507, save energy | 114P003 | iDesalt |

| for R-12(A), SS2507, save energy | 114P004 | iDesalt |

| for R-18(A), SS2507, save energy | 114P006 | iDesalt |

| for R-24(A), SS2507, save energy | 114P007 | iDesalt |

Touch screen kit |

| for R series, with SCADA | 115P001 | iDesalt |

UV kit |

| for R-6(A) and R-12(A) , SS304 | 117P003 | Wonder |

| for R-18(A) and R-24(A) , SS304 | 117P006 | Wonder |

| for R-48(A), SS304 | 117P009 | Wonder |

Filter kit |

| for R-6(A), for 1 year | 116P003 | iDesalt |

| for R-12(A), for 1 year | 116P004 | iDesalt |

| for R-18(A)/24(A), for 1 year | 116P006 | iDesalt |

| for R-48(A), for 1 year | 116P009 | iDesalt |

Extensive applications

System characteristics

Stability and reliability: We have nearly 30 years of experience in the design of desalination systems

Quick installation and commissioning: Most of the installation is completed before delivery. Better filtration: 3 steps filtering process including sand filter, pre-filter and main filter to ensure better protection for high pressure pump, energy recovery device and RO membrane

Long life: Using Sch40 duplex (EN1.4462/UNS S32205) high pressure pipe and fittings, SS304 frames and heavy duty powder coating

Low energy consumption: Using high-efficiency high pressure pump (super duplex pump based on axial piston principle) and low energy-consumption RO membrane

Low noise & vibration level: Using high pressure hose and vibration damper

Fast restoring: In case of malfunction, the whole system can be restored quickly by using standard parts

3 types: Manual, Auto and Turbo