MBR PTFE Flat Sheet Membrane for Sewage Treatment Plant

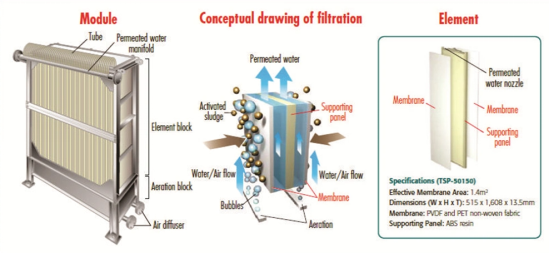

Membrane Bioreactor (MBR) is a new type of wastewater treatment technology that combines high-efficiency membrane separation technology with biochemical technology. The membrane module directly performs solid-liquid separation in the biochemical pool, replacing the secondary sedimentation tank in the activated sludge method, and effectively achieves the purpose of muddy water separation. The high-efficiency retention effect of the membrane allows the nitrifying bacteria to be completely retained in the bioreactor, so that the nitrification reaction can be smoothly carried out, the ammonia nitrogen can be effectively removed, the sludge can be avoided, and the macromolecular organic matter which is difficult to degrade can be retained at the same time, and the The residence time of the reactor is maximized. After applying MBR technology, the main pollution removal rate can reach: COD≥93%, the suspended solids and turbidity are close to zero, the water quality is good and stable, and it can be directly reused to realize the sewage resource.

Specification:

Membrane Bioreactor MBR sheet (pcs.)

Parameters | FN90 | FN150 |

Effective membrane area (m2) | 0.9 | 1.5 |

Overall size(L*B*H)(mm) | 1030*510*6 | 1650*510*6 |

Membrane pore size(μm) | 0.2~0.4 |

Membrane material | PTFE/PVDF |

Water yield (L/pcs·day) | 450~630 | 750~1050 |

Effluent turbidity (NTU) | <1.0 |

Suspended solids in effluent (SS,mg/L) | <1.0 |

Model (All customized models are available by online inquiry)

Parameters | FN90-100 | FN90-150 | FN150-100 | FN150-150 |

Number of membrane elements (pcs.) | 100 | 150 | 100 | 150 |

Effective membrane area (m2) | 90 | 135 | 150 | 225 |

Treatment capacity (m3/d) | 45 | 67.5 | 75 | 112.5 |

Aeration capacity(m3/min) | 1~1.2 | 1.5~1.8 | 1.5~2 | 2.25~3 |

Frame material | Stainless steel 304 |

Diffuser pipe material | Stainless steel 304/UPVC/ABS |

Collection pipe material | UPVC |

Advantage

1. High strength.

2. Good anti-pollution performance.

3. Super-large flux.

4. Good retention performance.

5. The cleaning flux recovery is good.

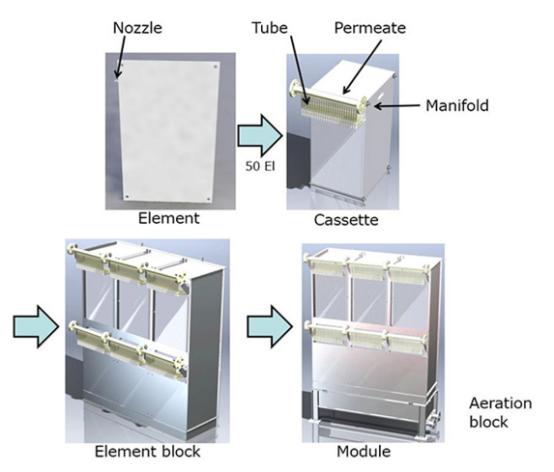

6. The reinforced composite PVDF membrane module can be modularized, compact in structure, small in footprint, and easy to use in combination.

7. Reinforced composite PVDF sewage treatment special diaphragm has a long service life, generally can reach 3-5 years.

8. The composite PVDF membrane has good chemical stability, acid and alkali resistance, bacterial corrosion resistance and good oxidation resistance.

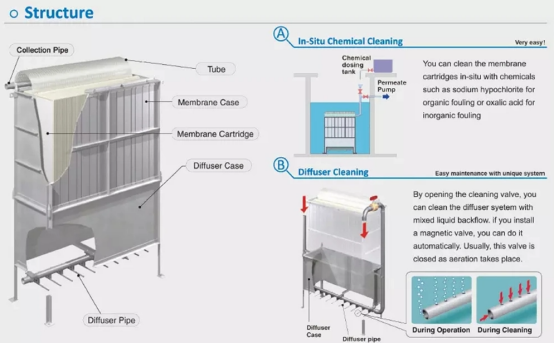

9. The membrane module is provided with an aeration tube to wash the membrane wire with water and water to maintain the flux of the membrane. The surface of the membrane fiber can also be cleaned by the aeration process of the biochemical pool to maintain a stable water production.

Applications

Municipal water supply

Industrial water purification

Boiler feed water, cooling water

Pharmaceutical manufacturing

Municipal waste water treatment

Reclaimed water reuse

Local sewage plants

Water processing and recycling facilities

Pretreatment process for drinking water

Pretreatment process for RO system

Landfill leachate advanced treatment