Ultrafiltration System Brief

UF is a method that physically removes particles of a certain size using the porous material. In the UF process the solution is pushed through the semipermeable membrane with a pore size of 0.005-0.1μm. Large particles and contaminants with high molecular weight are retained. At the same time, water and solutes with low molecular weight pass through the membrane. Thus, UF can be used not only for purification and concentration, but also for separation purposes. UF is just a physical process, it doesn’t cause any chemical changes in water. It also doesn’t form any byproducts. Because UF operates at a room temperature, it can be used for separation or filtration of heat-sensitive components. UF filtration can be used at water temperatures below 600C and with pH level of 2-11 in a 24-hours regime, providing convenient and reliable treatment.

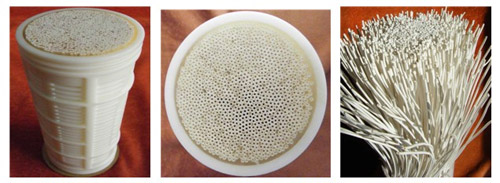

MEMBRANE TYPES

There are four main basic membrane configurations: plate and frame, tubular, spiral wound, and hollow fiber. The hollow fiber configuration is widely used because of its ability to be backwashed, self-supporting structure, and good recovery rate. Each hollow fiber tube has a diameter 0.4-2.0mm and has porous fiber walls with a molecular weight cut off (MWCO) numbers from tens to hundreds thousands Da. Feed water can flow in the tubes with permeate collected on the outside (inside-out), but the reverse connection is also possible(outside-in). The UF ability to be backwashed helps to prevent clogging of the membrane surface and provide long-term continuous operation.

Advantages

UF membranes are usually made of high-quality Polyvinylidiene Аlouride (PVDF), Polyvinyl chloride (PVC) or polysulfone (PSU) polymeric materials with high strength, flexibility, and chemical resistance to guarantee long lasting performance

UF doesn’t chemically modify water or create the byproducts

Low energy consumption, short treatment time and low operating cost, comparing to conventional treatment methods, can significantly reduce the production cost for the company

Monitoring system based on the individual needs and goals, combined with the advanced control software allows fully automatic operation and monitoring of critical process parameters. The alarm and shut-down options help to prevent equipment malfunction

Applications

Obtaining pure and ultrapure water

Food, beverage, and dairy production plants

Industrial separation, concentration and purification

Wastewater recycling

Industrial waste water treatment