DuPont Resins AmberLite HPR550 OH Ion Exchange Resin

In the water treatment industry, ion exchange resins are indispensable core materials, especially in scenarios requiring high-purity water. Among them, DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin stands out for its premium quality and outstanding performance, making it a key choice for power industry condensate polishing and mixed bed demineralization. This article will comprehensively introduce the product characteristics, application scenarios, technical parameters, and safe operation guidelines of this resin based on its official product data sheet (IER-AmberLite-HPR550-OH-PDS-45-D01191-en.pdf).

DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin is a premium-quality, high-capacity strong base anion exchange resin with a gel matrix, specifically designed for nuclear condensate polishing mixed beds where the highest resin purity and water quality are non-negotiable . Historically, this resin was sold under the name DOWEX MONOSPHERE™ 550A (OH) Ion Exchange Resin, a legacy that speaks to its long-standing reputation in the industry.

One of its core advantages lies in its exceptional bead integrity and rapid exchange kinetics, attributed to its small average particle size. This feature makes it perfectly suited to the high flowrate demands commonly encountered in power plant condensate polishing systems. Additionally, its light color and uniform bead size are tailored to complement DuPont’s AmberLite™ HPR650 H Ion Exchange Resin (a larger, denser cationic gel resin) — the color distinction between the two allows for easy visual confirmation of separation after backwashing, ensuring reliable mixed bed operation.

To understand the performance of DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin, its physical, chemical, and stability parameters (extracted from the product data sheet) are critical references:

| Parameter Category | Specific Indicators |

|

|---|

| Physical Properties | - Copolymer: Styrene-divinylbenzene

- Matrix: Gel

- Type: Strong base anion

- Functional Group: Trimethylammonium

- Physical Form: White to yellow, translucent, spherical beads

- Particle Diameter: 590 ± 50 µm

- Uniformity Coefficient: ≤ 1.10

- Particles < 300 µm: ≤ 0.5%; Particles > 850 µm: ≤ 1.0% |

|

| Chemical Properties | - Ionic Form (Shipped): OH⁻

- Total Exchange Capacity: ≥ 1.1 eq/L (OH⁻ form)

- Water Retention Capacity: 55.0 – 65.0% (OH⁻ form)

- Ionic Conversion: OH⁻ ≥ 95%; CO₃²⁻ ≤ 5%; Cl⁻ ≤ 0.5% |

|

| Purity | - Metals (Dry Basis): Na, K, Fe, Ca, Mg, Al ≤ 50 mg/kg; Cu ≤ 10 mg/kg; Heavy Metals (as Pb) ≤ 10 mg/kg |

|

| Stability | - Whole Uncracked Beads: ≥ 95%

- Friability: Average ≥ 350 g/bead; > 200 g/bead ≥ 95%

- Swelling (Cl⁻ → OH⁻): ≤ 25%

- Particle Density: 1.08 g/mL; Shipping Weight: 660 g/L |

|

These parameters collectively guarantee the resin’s low impurity content (avoiding secondary water pollution), high ion exchange efficiency, and long service life — essential for meeting strict water quality standards in industrial applications.

Mixed bed demineralization relies on the synergy between cation and anion exchange resins. For DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin, the product data sheet specifies the following pairings to maximize separation efficiency and water quality:

Recommended Pairing: AmberLite™ HPR650 H Ion Exchange Resin (gel type). This combination is industry-recognized as a premium mixed bed pairing, thanks to their complementary particle size, density, and color — ensuring easy separation and exceptional water purification results.

Additional Options:

AmberLite™ HPR1600 H Ion Exchange Resin (gel type) for flexible system adaptation.

AmberLite™ HPR2000 H Ion Exchange Resin (macroporous type), specifically designed for external regeneration systems.

DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin is engineered for scenarios requiring ultra-pure water, with key applications outlined in the product data sheet:

PWR Nuclear Power Plants: Critical for maintaining the purity of condensate in pressurized water reactor (PWR) systems, where even trace impurities can corrode equipment or compromise reactor safety.

Fossil Power Plants: Ensures condensate meets boiler feedwater standards, reducing scaling and corrosion in turbines and boilers.

Ideal for mixed bed polishing in industrial settings, particularly when:

Treating water with a high percentage of silica (a common contaminant that’s difficult to remove).

The treatment goal is to remove strong/weak acids or achieve lowest silica leakage (critical for industries like electronics and pharmaceuticals) .

Single bed industrial demineralization requires high water purity .

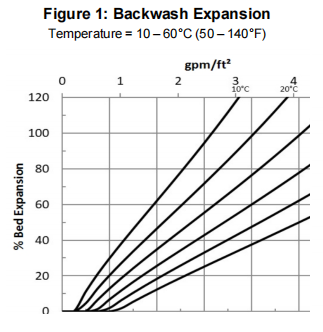

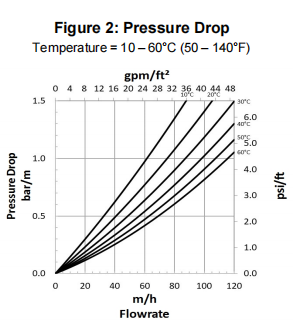

The product data sheet includes two key figures to guide system design: backwash expansion and pressure drop (critical for optimizing flow rates and avoiding resin damage).

This figure illustrates the estimated bed expansion of DuPont™ AmberLite™ HPR550 OH Ion Exchange Resin as a function of backwash flow rate (gpm/ft²) and temperature (10 – 60°C / 50 – 140°F) . Proper backwash expansion ensures resin regeneration and removes trapped impurities without excessive bead breakage.

This figure shows the estimated pressure drop of the resin as a function of service flow rate (gpm/ft² or m/h) and temperature (10 – 60°C / 50 – 140°F). The pressure drop values are valid at the start of the service run with clean water . Understanding this helps avoid excessive system pressure and ensures stable flow.

To ensure optimal performance and longevity, the product data sheet specifies the following operating parameters:

Temperature Range (OH⁻ Form): 5 – 100°C (41 – 212°F). Note that operating above 60 – 70°C (140 – 158°F) may impact loop purity and resin life — consult DuPont technical representatives for high-temperature guidance .

pH Range (Stable): 0 – 14, allowing adaptability to diverse water sources (e.g., acidic industrial wastewater or alkaline condensate) .

Additional Guidance: For minimum bed depth, regeneration conditions for mixed beds (Form No. 45-D01127-en) or separate beds (Form No. 45-D01131-en), refer to DuPont’s Tech Facts documents .

A critical safety note from the product data sheet: oxidizing agents (e.g., nitric acid) can attack organic ion exchange resins under certain conditions, leading to resin degradation or even violent exothermic reactions (explosions) . Always consult experts in handling oxidizing agents before use, and follow DuPont’s safety data sheets (available upon request) for full risk mitigation guidelines .

We prioritize the safety of those involved in the manufacture, distribution, and use of our products, as well as the protection of the environment, through our product stewardship philosophy. This includes providing technical support, safety data sheets, and guidance to ensure our resins are used as intended. We encourage customers to review their production processes for compliance with health and environmental requirements, and our staff are always available to answer any questions.

Website: You can visit the official website https://www.fgwater.com/Ion-Exchange-and-Adsorption-Resin/ to learn more about product information and solutions.

Tel: +86-13646187144 or +86-510-85163211

Email: [email protected] to consult product details, obtain quotations, and carry out purchase negotiations.

Address: 511#, BLOCK B, NATIONAL INDUSTRIAL DESIGN PARK, DICUI ROAD 100, BINHU DISTRICT, WUXI, JIANGSU, China