DuPont™ AmberLite™ HPR650 H Ion Exchange Resin

In the field of water treatment, ion exchange resins are core materials that realize high-purity water purification. Among them, DuPont™ AmberLite™ HPR650 H Ion Exchange Resin stands out with its premium quality, high capacity, and uniform particle size, becoming a key choice for condensate polishing in the power industry and mixed bed demineralization scenarios. This article will deeply explore the role of ion exchange resins in water treatment, and comprehensively introduce the product characteristics, application scenarios, technical parameters, and safe operation guidelines of DuPont™ AmberLite™ HPR650 H Ion Exchange Resin based on its official product data sheet (IER-AmberLite-HPR650-H-PDS-45-D01193-en.pdf).

Ion exchange resins are mainly divided into three categories: cation exchange resins, anion exchange resins, and mixed bed ion exchange resins, each undertaking unique water purification tasks to meet the diverse needs of industrial and domestic water treatment.

Cation Exchange Resins: Focus on exchanging cations in water. For example, they can replace calcium, magnesium, and other hardness-causing cations with sodium ions, effectively reducing water hardness and preventing scaling in pipelines and equipment. This is crucial for protecting boilers, heat exchangers, and other industrial equipment.

Anion Exchange Resins: Target anionic impurities in water. They can exchange harmful anions such as chloride, arsenic, and nitrate with harmless anions (like hydroxide ions), reducing the content of toxic and harmful substances in water and improving water safety.

Mixed Bed Ion Exchange Resins: A physical mixture of cation and anion exchange resins. It can simultaneously remove cations and anions in water in a single treatment process, avoiding the need for multiple separate treatment steps. This not only simplifies the water treatment process but also significantly improves water purity, making it suitable for scenarios requiring ultra-pure water, such as semiconductor manufacturing and pharmaceutical production.

DuPont™ AmberLite™ HPR650 H Ion Exchange Resin, as a high-performance strong acid cation exchange resin, plays a vital role in the mixed bed water treatment system. It cooperates with matching anion exchange resins to achieve efficient and deep purification of water quality.

DuPont™ AmberLite™ HPR650 H Ion Exchange Resin is a premium-quality, high-capacity strong acid cation exchange resin with a gel matrix and uniform particle size. It is specifically designed for nuclear condensate polishing mixed beds where the highest resin purity and water quality are non-negotiable.

Historically, this resin was sold under the name DOWEX MONOSPHERE™ 650C (H) Ion Exchange Resin, and its long-term application in the industry has established a good reputation for reliability and stability. Its core advantages are reflected in two key aspects:

Excellent Mechanical Strength & Oxidative Stability: It can withstand the high flow rate requirements of condensate polishing systems in power plants without bead breakage or performance degradation due to mechanical wear. At the same time, it has strong resistance to oxidation, reducing the risk of resin degradation caused by oxidizing substances in water and extending the service life.

Optimized Matching with Anion Resins: The resin has uniform bead size and a dark amber color, which is precisely tailored to match DuPont’s AmberLite™ HPR550 OH Ion Exchange Resin (a smaller, less dense gel-type anion resin). The obvious color difference between the two resins allows operators to easily visually confirm the separation effect of the resins after backwashing, ensuring the stable operation of the mixed bed system. In addition, for systems requiring exceptional resistance to surface fouling, it can also be paired with macroporous AmberLite™ HPR9000 OH Ion Exchange Resin to further enhance the anti-fouling performance of the system.

The excellent performance of DuPont™ AmberLite™ HPR650 H Ion Exchange Resin is supported by its superior physical, chemical, and stability parameters. The following table extracts key indicators from the official product data sheet for detailed explanation:

| Parameter Category | Specific Indicators | Significance |

|---|

| Physical Properties | - Copolymer: Styrene-divinylbenzene

- Matrix: Gel

- Type: Strong acid cation

- Functional Group: Sulfonic acid

- Physical Form: Dark amber, translucent, spherical beads

- Particle Diameter: 650 ± 50 µm

- Uniformity Coefficient: ≤ 1.10

- Particles < 300 µm: ≤ 0.5%; Particles > 850 µm: ≤ 5.0% | - Styrene-divinylbenzene copolymer ensures resin stability; gel matrix provides efficient ion exchange channels.

- Uniform particle size (uniformity coefficient ≤ 1.10) ensures stable water flow, avoids uneven flow caused by particle size differences, and improves ion exchange efficiency. |

| Chemical Properties | - Ionic Form (Shipped): H⁺

- Total Exchange Capacity: ≥ 2.0 eq/L (H⁺ form)

- Water Retention Capacity: 46.0 – 52.0% (H⁺ form)

- Ionic Conversion: H⁺ ≥ 99% | - High total exchange capacity (≥ 2.0 eq/L) means strong ion adsorption capacity, which can handle more ion-containing water per unit volume of resin.

- H⁺ conversion rate ≥ 99% ensures that the resin is in an active state when shipped, and can quickly start ion exchange work without additional activation steps. |

| Purity | - Metals (Dry Basis): Na ≤ 50 mg/kg; Fe ≤ 50 mg/kg; Cu ≤ 10 mg/kg; Al ≤ 50 mg/kg; Heavy Metals (as Pb) ≤ 10 mg/kg | Ultra-low impurity content avoids secondary pollution of water during the ion exchange process, which is crucial for scenarios with strict water quality requirements (such as nuclear power plant condensate polishing). |

| Stability | - Whole Uncracked Beads: ≥ 95%

- Friability: Average ≥ 500 g/bead; > 200 g/bead ≥ 95%

- Swelling (Na⁺ → H⁺): 7%

- Particle Density: 1.22 g/mL; Shipping Weight: 785 g/L | - High proportion of whole uncracked beads and strong friability (average ≥ 500 g/bead) ensure that the resin is not easily broken during backwashing and regeneration, reducing resin loss and system maintenance costs.

- Low swelling rate (only 7%) avoids equipment damage caused by excessive volume expansion of the resin, ensuring the stable operation of the water treatment system. |

These parameters collectively form the "performance guarantee" of DuPont™ AmberLite™ HPR650 H Ion Exchange Resin, making it capable of meeting the strict requirements of high-purity water treatment.

The performance of mixed bed water treatment systems depends not only on the quality of a single resin but also on the synergy between cation and anion resins. For DuPont™ AmberLite™ HPR650 H Ion Exchange Resin, the official product data sheet provides clear pairing recommendations to adapt to different application scenarios:

AmberLite™ HPR550 OH Ion Exchange Resin (Gel Type): This is the classic "premium pairing" recognized in the industry. The two resins complement each other in particle size (HPR650 H: 650 ± 50 µm; HPR550 OH: 590 ± 50 µm) and density (HPR650 H: 1.22 g/mL; HPR550 OH: 1.08 g/mL), and the obvious color difference (dark amber vs. light color) allows easy visual confirmation of separation after backwashing. Together, they can achieve exceptional separation efficiency and water purification quality, which is widely used in nuclear power plants and fossil power plants.

AmberLite™ HPR9000 OH Ion Exchange Resin (Macroporous Type): Recommended for systems requiring strong surface fouling resistance. The macroporous structure of HPR9000 OH Ion Exchange Resin can effectively trap colloidal substances and organic impurities in water, preventing fouling on the resin surface. When paired with HPR650 H Ion Exchange Resin, it is suitable for water treatment scenarios with high organic matter content or severe fouling risks.

AmberLite™ HPR550 Cl Ion Exchange Resin (Gel Type): It can be used as an alternative to HPR550 OH Ion Exchange Resin in specific chloride-containing water environments, expanding the application scope of the system.

AmberLite™ HPR9000 SO₄²⁻ Ion Exchange Resin (Macroporous Type): For water bodies with high sulfate content, this pairing can efficiently remove sulfate ions while ensuring the purification effect of cations, making the water quality meet the required standards.

DuPont™ AmberLite™ HPR650 H Ion Exchange Resin is designed for scenarios requiring ultra-pure water, and its application scope is clearly defined in the official product data sheet, mainly covering the following fields:

PWR Nuclear Power Plants: In pressurized water reactor (PWR) nuclear power plants, the purity of condensate directly affects the safety of the reactor core and the service life of key equipment. This resin can deeply remove trace cations (such as sodium, iron, and copper) in the condensate, avoiding corrosion of the reactor coolant system and ensuring the stable operation of the nuclear power plant.

Fossil Power Plants: For thermal power plants using coal, oil, or natural gas as fuel, the quality of boiler feedwater is crucial for preventing scaling and corrosion of boilers and turbines. DuPont™ AmberLite™ HPR650 H Ion Exchange Resin, when paired with anion resins, can effectively reduce the hardness and cation content of condensate, ensuring that the feedwater meets the strict standards of power plant boilers and improving the thermal efficiency of the power plant.

In industrial production processes that require high-purity water (such as chemical synthesis, electronic chip manufacturing, and pharmaceutical preparation), mixed bed demineralization systems using this resin can achieve the following effects:

Remove various cations in water (such as calcium, magnesium, potassium, and sodium) to avoid the impact of cation impurities on product quality.

Cooperate with anion resins to realize the deep removal of strong and weak acids, ensuring that the conductivity of the treated water is significantly reduced and meeting the ultra-pure water requirements of industrial processes.

The hydraulic characteristics of ion exchange resins (including backwash expansion and pressure drop) are key factors affecting the design and operation of water treatment systems. The official product data sheet of DuPont™ AmberLite™ HPR650 H Ion Exchange Resin provides two core figures to guide practical applications:

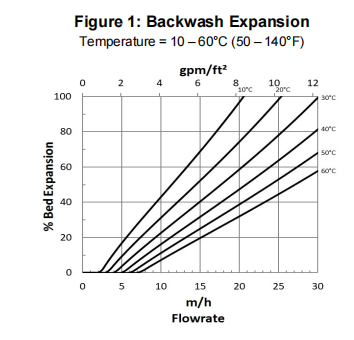

This figure shows the estimated bed expansion rate of the resin as a function of backwash flow rate (unit: m/h) and temperature (10 – 60°C / 50 – 140°F). Backwashing is a critical step in the resin regeneration process, which can remove impurities trapped between resin beads and restore the ion exchange capacity of the resin.

Key Significance: Proper bed expansion (usually 50% – 80%) ensures that impurities are fully washed away without excessive expansion leading to resin loss or insufficient expansion resulting in incomplete impurity removal. For example, at a temperature of 25°C, when the backwash flow rate is 10 m/h, the bed expansion rate of the resin is about 40%; when the flow rate is increased to 20 m/h, the expansion rate can reach 80%, which can be adjusted according to the actual impurity content in water.

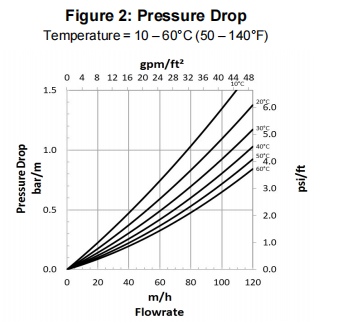

This figure reflects the estimated pressure drop of the resin bed as a function of service flow rate (unit: m/h or gpm/ft²) and temperature (10 – 60°C / 50 – 140°F). The pressure drop data is valid when clean water is used at the start of the service cycle.

Key Significance: Excessive pressure drop will increase the energy consumption of the water treatment system and may cause damage to the resin bed; too low pressure drop may indicate insufficient contact between water and resin, affecting the ion exchange effect. For example, at a temperature of 20°C and a service flow rate of 20 m/h, the pressure drop of the resin bed is about 2.0 kPa/m, which is within the reasonable operation range of most water treatment systems.

To give full play to the performance of DuPont™ AmberLite™ HPR650 H Ion Exchange Resin and extend its service life, the official product data sheet specifies the following operating parameters:

The applicable temperature range of the resin in the H⁺ form is 5 – 150°C (41 – 302°F), which is wider than that of many similar cation exchange resins. This advantage allows it to adapt to high-temperature water treatment scenarios, such as high-temperature condensate polishing in power plants. However, it should be noted that when operating at temperatures close to the upper limit (above 120°C), it is recommended to consult DuPont technical representatives to adjust the system parameters according to the actual water quality, to avoid excessive temperature affecting the resin's long-term stability.

The resin has excellent stability in the pH range of 0 – 14, which means it can work normally in both strongly acidic and strongly alkaline water environments. This adaptability is particularly important for industrial wastewater treatment or mixed bed systems that require acid-base regeneration, as it avoids the need for additional pH adjustment steps and simplifies the system process.

For key parameters such as the recommended minimum bed depth of the resin, specific operating conditions (such as flow rate control), and regeneration conditions (such as acid concentration and dosage) in mixed beds or separate beds, please refer to DuPont’s special technical documents:

These documents provide detailed operational guidelines to help users optimize the water treatment system and achieve the best purification effect.

When using DuPont™ AmberLite™ HPR650 H Ion Exchange Resin, safety must be the top priority. The official product data sheet emphasizes the following key warnings:

WARNING: Oxidizing agents such as nitric acid may attack organic ion exchange resins under certain conditions. This can lead to slight resin degradation (such as reduced exchange capacity) or even violent exothermic reactions (including explosions) in severe cases. Before using strong oxidizing agents in the water treatment system (such as disinfection with high-concentration oxidants), it is necessary to consult professionals familiar with the handling of such materials, formulate scientific operating procedures, and conduct pre-tests to ensure that the resin and oxidizing agents are compatible under the current conditions.

In addition, when replacing or regenerating the resin, operators should wear appropriate protective equipment (such as gloves, goggles, and overalls) to avoid direct contact with the resin or regeneration chemicals, and ensure good ventilation in the operation area to prevent the accumulation of harmful gases.

If you are interested in DuPont™ AmberLite™ HPR650 H Ion Exchange Resin or need a complete set of water treatment solutions (including matching anion resins, system equipment, etc.), you can purchase and consult through FG Water Technologies. As a high-tech enterprise integrating water treatment equipment design, manufacturing, trade, and transportation, FG Water Technologies can provide professional technical support and customized solutions to meet your diverse water treatment needs.

Official Website: Visit https://www.fgwater.com/Ion-Exchange-and-Adsorption-Resin/ to view detailed product information, technical documents, and case studies of water treatment systems.

Telephone Contact:

Mobile: +86-13646187144

Office: +86-510-85163211

Email Consultation: Send your needs (such as product specifications, purchase quantity, and application scenarios) to [email protected], and the professional team of FG Water Technologies will reply to you within 24 hours to provide quotations and technical advice.

Company Address: 511#, BLOCK B, NATIONAL INDUSTRIAL DESIGN PARK, DICUI ROAD 100, BINHU DISTRICT, WUXI, JIANGSU, China

In addition to DuPont ion exchange resins, FG Water Technologies also provides a full range of water treatment equipment, including containerized water purification systems, seawater reverse osmosis (SWRO) systems, brackish water reverse osmosis (BWRO) systems, ultrafiltration membrane