DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin

In the field of water treatment, ion exchange resins are essential for achieving efficient purification and meeting diverse water quality demands—from industrial softening to high-purity water production. Among these resins, DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin stands out as a high-performance solution tailored for industrial softening and demineralization scenarios. This article will systematically introduce the classification and role of ion exchange resins in water treatment, then dive into the technical characteristics, application scenarios, and safe operation guidelines of DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin (based on its official product data sheet: IER-AmberLite-HPR1200-Na-PDS-45-D01222-en.pdf), providing a comprehensive reference for industries seeking reliable water treatment materials.

Ion exchange resins realize water purification by exchanging harmful ions in water with harmless ones, and they are mainly divided into three categories according to their functional properties, each undertaking unique purification tasks:

Cation Exchange Resins: Specialized in removing positively charged ions (cations) such as calcium (Ca²⁺), magnesium (Mg²⁺), and sodium (Na⁺) from water. They are widely used in water softening processes—by replacing hardness-causing cations (Ca²⁺, Mg²⁺) with sodium ions (Na⁺), they prevent scaling in industrial equipment like boilers, heat exchangers, and pipelines, thus extending equipment service life and reducing maintenance costs.

Anion Exchange Resins: Target negatively charged ions (anions) including chloride (Cl⁻), sulfate (SO₄²⁻), and silica (SiO₂). They are critical for deep demineralization, especially in scenarios requiring ultra-pure water (e.g., semiconductor manufacturing, pharmaceutical production), where even trace anionic impurities can compromise product quality or system safety.

Mixed Bed Ion Exchange Resins: A physical mixture of cation and anion resins that can simultaneously remove both cations and anions in a single treatment step. This type of resin simplifies the water treatment process and significantly improves water purity, making it suitable for high-end applications like laboratory ultra-pure water preparation and nuclear power plant condensate polishing.

DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin, as a high-quality strong acid cation resin, plays a key role in the above systems—especially in industrial softening, where its optimized performance ensures efficient and cost-effective water treatment.

DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin is a uniform particle size, gel-type strong acid cation exchange resin designed for industrial softening and demineralization applications that demand high performance and cost efficiency. Historically, this resin was sold under the well-regarded brand name DOWEX MARATHON™ 1200 Na, a legacy that reflects its long-standing reliability and market recognition in the water treatment industry.

The resin’s excellent performance is supported by its superior physical and chemical properties, which bring tangible benefits to practical applications:

Optimized Operating Capacity & Rinse Characteristics: Its chemical composition and particle size have been precisely adjusted to deliver high operating capacity—meaning it can adsorb more cations per unit volume, reducing resin dosage and equipment footprint. Additionally, it exhibits excellent rinse performance, requiring less rinse water to remove residual regenerants, thus lowering water and chemical consumption costs.

Broad System Compatibility: The resin is compatible with all common water treatment system technologies, including co-current, counter-current/hold-down, packed beds, and mixed beds. This versatility allows it to be seamlessly integrated into existing or new water treatment systems, eliminating the need for expensive system modifications.

Ultra-Low Fine Particle Content: The particle size distribution is strictly controlled—particles smaller than 300 μm account for ≤ 0.1%, and those larger than 850 μm for ≤ 3.0%. This minimizes the risk of system clogging, ensures stable water flow through the resin bed, and avoids uneven flow (channeling) that reduces ion exchange efficiency.

The following table summarizes the typical properties of DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin (extracted from its official product data sheet), providing a clear technical reference for users:

| Property Category | Specific Indicators |

|---|

| Physical Properties | - Copolymer: Styrene-divinylbenzene

- Matrix: Gel

- Type: Strong acid cation

- Functional Group: Sulfonic acid

- Physical Form: Dark brown, translucent, spherical beads

- Particle Diameter: 585 ± 50 μm

- Uniformity Coefficient: ≤ 1.10 |

| Chemical Properties | - Ionic Form (as shipped): Na⁺

- Total Exchange Capacity: ≥ 2.0 eq/L (Na⁺ form)

- Water Retention Capacity: 43.0 – 50.0% (Na⁺ form) |

| Stability | - Whole Uncracked Beads: ≥ 95%

- Swelling (Ca²⁺ → Na⁺): 5%; (Na⁺ → H⁺): 8%

- Particle Density: 1.29 g/mL

- Shipping Weight: 820 g/L |

| Operating Range | - Temperature Range (Na⁺ form): 5 – 150°C (41 – 302°F)

- pH Range (Service Cycle): 1 – 14; (Stable): 0 – 14 |

These properties collectively ensure the resin’s high efficiency, durability, and adaptability to diverse operating environments—critical for meeting the rigorous demands of industrial water treatment.

Based on its performance characteristics and official positioning, DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin is mainly applied in two core scenarios:

This is the resin’s primary application field. In industries such as power generation, chemical processing, and food and beverage production, hard water (rich in Ca²⁺, Mg²⁺) can cause scaling in boilers, heat exchangers, and pipelines—reducing heat transfer efficiency and increasing the risk of equipment corrosion or failure. DuPont™ AmberLite™ HPR1200 Na effectively replaces Ca²⁺ and Mg²⁺ in water with Na⁺, softening the water and preventing scaling. Its high operating capacity and low rinse water requirement make it a cost-effective choice for large-scale industrial softening systems.

When users prefer the sodium-form resin for demineralization processes (e.g., in certain chemical production lines where trace H⁺ may affect product stability), DuPont™ AmberLite™ HPR1200 Na is an ideal option. It works with anion exchange resins to remove cations in water, laying the foundation for deep demineralization. For detailed application guidelines in demineralization, users can refer to the product data sheet of AmberLite™ HPR1200 H Ion Exchange Resin (the hydrogen-form counterpart of this resin).

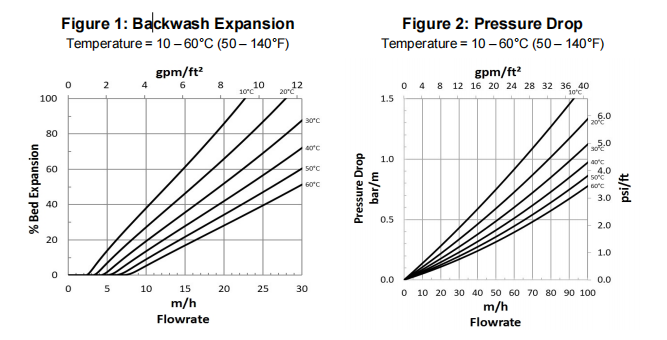

The hydraulic characteristics of ion exchange resins—including backwash expansion and pressure drop—are critical for optimizing system design and ensuring stable operation. The official product data sheet of DuPont™ AmberLite™ HPR1200 Na provides key guidance in this regard:

Backwashing is essential for removing trapped impurities (e.g., suspended solids) from the resin bed and regenerating the resin’s adsorption capacity. The estimated bed expansion of DuPont™ AmberLite™ HPR1200 Na varies with backwash flow rate and temperature (10 – 60°C / 50 – 140°F), as shown in Figure 1 of the product data sheet. Proper backwash expansion (typically 50% – 80%) ensures thorough impurity removal without excessive resin loss—operators can refer to the figure to determine the optimal backwash flow rate for their specific temperature conditions.

Pressure drop reflects the resistance of the resin bed to water flow. Excessive pressure drop increases energy consumption and may damage the resin or equipment, while too low a pressure drop may indicate insufficient contact between water and resin. The estimated pressure drop of DuPont™ AmberLite™ HPR1200 Na is a function of service flow rate and temperature (10 – 60°C / 50 – 140°F), as shown in Figure 2 of the product data sheet. These pressure drop values are valid at the start of the service run with clean water, providing a baseline for system pressure monitoring and flow rate adjustment.

To maximize the performance and lifespan of DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin, it is critical to follow official operating guidelines and safety requirements:

Minimum Bed Depth & Regeneration Conditions: For detailed parameters such as recommended minimum bed depth, operating flow rates, and regeneration chemical dosage (for mixed beds or separate beds), users should refer to DuPont’s Tech Facts documents—specifically Form No. 45-D01127-en (mixed beds) and Form No. 45-D01131-en (separate beds). These documents provide scenario-specific guidance to ensure optimal resin performance.

Temperature & pH Control: The resin operates effectively within a temperature range of 5 – 150°C (41 – 302°F) in the Na⁺ form. However, prolonged operation at temperatures near the upper limit (e.g., above 120°C) may accelerate resin aging, so it is recommended to consult DuPont technical representatives for high-temperature application adjustments. In terms of pH, it maintains stability across 0 – 14 and performs well in the 1 – 14 range during service cycles, adapting to most industrial water sources without additional pH adjustment.

WARNING: Oxidizing agents (e.g., nitric acid) can attack organic ion exchange resins under certain conditions—this may result in slight resin degradation (reduced capacity) or even violent exothermic reactions (explosions) in severe cases. Before using strong oxidizing agents in the water treatment system, users must consult professionals with expertise in handling such materials and strictly follow safety operating procedures.

Additionally, operators should wear appropriate personal protective equipment (e.g., chemical-resistant gloves, goggles, and overalls) when handling the resin or regeneration chemicals. They should also review DuPont’s Safety Data Sheets (SDS) for the resin prior to use—current SDS documents are available upon request from DuPont.

If you are interested in DuPont™ AmberLite™ HPR1200 Na Ion Exchange Resin or need other water treatment equipment and solutions, you can purchase and consult through FG Water Technologies—a high-tech enterprise integrating water treatment equipment design, manufacturing, trade, and shipment, and a trusted partner for industrial water treatment needs.

Official Website: Visit https://www.fgwater.com/International-Brand-Resins/ to browse detailed product information, technical documents, and case studies of water treatment systems.

Telephone Contact:

Email Consultation: Send your requirements (e.g., application scenario, water volume, expected water quality) to [email protected], and FG Water Technologies’ professional technical team will provide a tailored solution and quotation within 24 hours.

In addition to DuPont ion exchange resins, FG Water Technologies also offers a full range of water treatment equipment, including containerized water purification systems, seawater reverse osmosis (SWRO) systems, brackish water reverse osmosis (BWRO) systems, and ultrafiltration membrane modules. It can provide customized water treatment solutions according to your specific needs, ensuring that your water treatment processes are efficient, stable, and cost-effective.