DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin

HPR4200 Cl Ion Exchange Resin In the field of industrial water treatment, ion exchange resin is a core material that realizes deep purification of water quality, especially in demineralization scenarios. Among the many ion exchange resins, DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin stands out with its high performance, cost-effectiveness, and wide compatibility. It becomes an ideal choice for enterprises pursuing efficient and economical water treatment. This article will first elaborate on the important role of ion exchange resin in water treatment, then systematically introduce the product characteristics, application scenarios, technical parameters, and safe operation guidelines of DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin based on its official product data sheet (IER-AmberLite-HPR4200-Cl-PDS-45-D01229-en.pdf), providing a comprehensive reference for industrial users.

Ion exchange resins achieve water purification by exchanging ions with impurities in water, and they are mainly divided into cation exchange resins, anion exchange resins, and mixed bed ion exchange resins according to their functions, each playing a unique role:

Cation Exchange Resins: Focus on removing positively charged ions (cations) in water, such as calcium, magnesium, and sodium ions. They are widely used in water softening to prevent scaling of industrial equipment and ensure the normal operation of production processes.

Anion Exchange Resins: Specialize in adsorbing and exchanging negatively charged ions (anions) in water, including chloride, sulfate, and silica. DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin, as a high-quality strong base anion exchange resin, is excellent at removing these anions, especially silica which is difficult to handle, and plays a crucial role in deep demineralization.

Mixed Bed Ion Exchange Resins: A physical mixture of cation and anion exchange resins. It can simultaneously remove cations and anions in water in a single treatment process, significantly improving water purification efficiency and purity. It is suitable for scenarios requiring ultra-pure water, such as electronic manufacturing and pharmaceutical production.

In industrial demineralization systems, the combination of cation and anion exchange resins (like DuPont™ AmberLite™ HPR4200 Cl paired with cation resins) forms a efficient purification system, ensuring that the treated water meets the strict water quality standards of various industries.

DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin is a uniform particle size, gel-type strong base anion exchange resin, specially designed for industrial demineralization applications. It balances excellent operating capacity and low pressure drop through optimized chemical properties and particle size, while reducing the consumption of chemical regenerants and rinse water, achieving both high efficiency and cost-effectiveness.

Historically, this resin was sold under the name DOWEX MARATHON™ 4200 Cl Ion Exchange Resin. With its stable performance and reliable quality, it has accumulated a good reputation in the industry and become a trusted choice for many enterprises.

Wide System Compatibility: The resin is compatible with all system technologies and bed configurations, including mixed beds, packed beds, layered beds, counter-current/hold-down systems, and co-current systems. This strong compatibility allows it to be seamlessly integrated into various existing or newly-built water treatment systems, eliminating the need for expensive system transformation and reducing the difficulty and cost of application.

Flexible Application Modes: It can be used in lead single anion beds, layered anion beds, and mixed bed polishers. Enterprises only need to stock this one strong base anion resin to meet their different demineralization needs, simplifying inventory management and reducing inventory costs. In mixed bed applications, its light color design enables easy visual distinction from dark-colored cation resins after backwash separation, facilitating operators to check the separation effect and ensure the stable operation of the system.

Excellent Performance & Cost-Effectiveness: While having excellent operating capacity, the resin maintains a low pressure drop, ensuring stable water flow in the system and reducing energy consumption. At the same time, it reduces the usage of chemical regenerants and rinse water, lowering the daily operating costs of the water treatment system, which is of great significance for long-term large-scale industrial applications.

The excellent performance of DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin is supported by its superior technical parameters. The following table sorts out the key indicators from the official product data sheet for users' reference:

| Parameter Category | Specific Indicators |

|---|

| Basic Properties | - Type: Strong base anion exchange resin

- Matrix: Gel

- Copolymer: Styrene-divinylbenzene

- Physical Form: Light-colored spherical beads (facilitating distinction from dark cation resins)

- Ionic Form (as Shipped): Cl⁻ |

| Chemical Properties | - Total Exchange Capacity: ≥ 1.30 eq/L (Cl⁻ form)

- Water Retention Capacity: 49.0 – 55.0% (Cl⁻ form)

- Swelling (Cl⁻ → OH⁻): 20% |

| Particle Size | - Particle Diameter: 650 ± 50 μm

- Uniformity Coefficient: ≤ 1.25

- Content of Particles < 300 μm: ≤ 0.3%

- Content of Particles > 850 μm: ≤ 5.0% |

| Stability | - Whole Uncracked Beads: ≥ 90%

- Particle Density: 1.07 g/mL |

| Operating Range | - Temperature Range (Service): 5 – 60°C (41 – 140°F); (Maximum Tolerance): 5 – 100°C (41 – 212°F) [Note: Operating above 60 – 70°C may affect resin life]

- pH Range (Service Cycle): 1 – 14; (Stable): 0 – 14 |

These parameters comprehensively reflect the resin's ion exchange capacity, physical stability, and adaptability to operating environments, providing a solid technical basis for its application in industrial demineralization.

Based on its performance characteristics and official positioning, DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin is mainly applied in the following core scenarios:

This is the main application field of the resin. It is particularly suitable for treating water with a high percentage of silica. In industrial production processes such as chemical engineering, electronics, and power generation, the content of silica and strong/weak acids in water has a significant impact on product quality and equipment safety. This resin can efficiently remove strong and weak acids in water and minimize silica leakage, ensuring that the treated water meets the demineralization requirements of industrial production. For example, in chemical production, it can prevent the interference of anionic impurities on chemical reactions, improving product yield and purity; in electronic manufacturing, it can provide high-purity water to ensure the normal operation of chip production processes.

In mixed bed water treatment systems, the resin can be used for polishing treatment. When users prefer the chloride-form resin, it can replace the recommended AmberLite™ HPR4200 OH Ion Exchange Resin in mixed bed applications. It works with cation exchange resins to further improve water purity, making the water quality meet the higher standards required by precision industries.

To give full play to the performance of DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin and achieve the best demineralization effect, the official product data sheet provides clear pairing recommendations for different application scenarios:

AmberLite™ HPR1200 H Ion Exchange Resin (Gel Type): This pairing is suitable for mixed bed demineralization systems that pursue high efficiency and cost-effectiveness. The two resins complement each other in performance, enabling efficient removal of cations and anions in water and ensuring excellent water purification quality.

AmberLite™ HPR1300 H Ion Exchange Resin (Gel Type): As another recommended mixed bed pairing option, it can adapt to different water quality conditions and system design requirements, providing flexibility for users' choices.

AmberLite™ HPR9500 Ion Exchange Resin (Macroporous Type): This macroporous resin is suitable for layered bed systems. It has strong adsorption capacity for specific impurities and can cooperate with DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin to achieve layered purification of water, improving the overall demineralization efficiency of the system.

AmberLite™ HPR9600 Ion Exchange Resin (Macroporous Type): Another ideal pairing for layered bed systems. Its unique macroporous structure is conducive to the adsorption and exchange of impurities, and it can form a efficient layered bed purification system with the resin, meeting the demineralization needs of complex water quality.

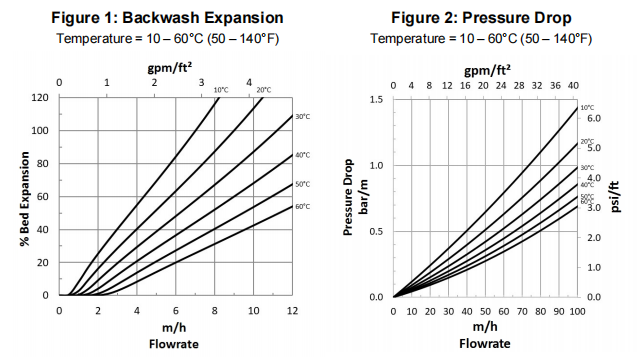

The hydraulic characteristics of the resin directly affect the operation efficiency and stability of the water treatment system. The official product data sheet provides two key hydraulic parameters:

Backwash Expansion: The estimated bed expansion of DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin varies with backwash flow rate and temperature (10 – 60°C / 50 – 140°F), as shown in Figure 1 of the data sheet. Proper backwash expansion (generally 40% – 80%) is conducive to removing impurities trapped in the resin bed and regenerating the resin's adsorption capacity. Operators can adjust the backwash flow rate according to the actual temperature and impurity content to ensure the backwash effect.

Pressure Drop: The estimated pressure drop of the resin changes with the service flow rate and temperature (10 – 60°C / 50 – 140°F), as shown in Figure 2 of the data sheet. The pressure drop data is valid when clean water is used at the start of the service run. Excessive pressure drop will increase the energy consumption of the system and may damage the resin or equipment; too low pressure drop may indicate insufficient contact between water and resin, affecting the ion exchange effect. Operators need to monitor the system pressure in real time and adjust the flow rate within a reasonable range.

Temperature Control: The recommended service temperature range of the resin is 5 – 60°C (41 – 140°F). Although it can tolerate a maximum temperature of 5 – 100°C (41 – 212°F), operating at elevated temperatures (such as above 60 – 70°C / 140 – 158°F) may affect the service life of the resin. Therefore, when operating at high temperatures, it is necessary to consult DuPont's technical representatives in advance to obtain professional guidance and ensure the stable operation of the resin.

pH Adaptability: The resin has good stability in the pH range of 0 – 14 and can operate normally in the pH range of 1 – 14 during the service cycle. This wide pH adaptability allows it to cope with various acidic and alkaline water sources in industrial production without additional pH adjustment steps, simplifying the operation process.

Additional Guidance: For parameters such as the recommended minimum bed depth of the resin, specific operating conditions, and regeneration conditions in mixed beds or separate beds, please refer to DuPont's technical documents (Form No. 45-D01127-en for mixed beds and Form No. 45-D01131-en for separate beds). These documents provide detailed operational guidelines to help users optimize the water treatment system.

When using DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin, safety must be the top priority. The official product data sheet emphasizes the following key warnings:

WARNING: Oxidizing agents such as nitric acid may attack organic ion exchange resins under certain conditions. This can lead to slight resin degradation (such as reduced exchange capacity) or even violent exothermic reactions (including explosions) in severe cases. Before using strong oxidizing agents in the water treatment system (such as disinfection with high-concentration oxidants), it is necessary to consult professionals familiar with the handling of such materials, formulate scientific operating procedures, and conduct pre-tests to ensure that the resin and oxidizing agents are compatible under the current conditions.

In addition, when replacing or regenerating the resin, operators should wear appropriate protective equipment (such as chemical-resistant gloves, goggles, and overalls) to avoid direct contact with the resin or regeneration chemicals. At the same time, ensure good ventilation in the operation area to prevent the accumulation of harmful gases and avoid potential safety hazards.

If you are interested in DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin or need customized industrial water treatment solutions (including matching cation resins, system design, and technical support), you can purchase and consult through FG Water Technologies. As a professional enterprise focusing on water treatment, FG Water Technologies provides one-stop services from product supply to technical guidance, ensuring that your water treatment needs are fully met.

Official Website: Visit https://www.fgwater.com/Ion-Exchange-and-Adsorption-Resin/ to browse detailed product information, technical documents, and successful case studies of water treatment systems.

Telephone Contact:

Mobile: +86-13646187144 (available 24/7 for urgent consultations and technical inquiries)

Office: +86-510-85163211 (weekday business hours for project quotes, order placement, and in-depth technical communication)

Email Consultation: Send your specific needs (such as application scenario, water volume, water quality indicators, and expected treatment effect) to [email protected]. The professional technical team of FG Water Technologies will reply to you within 24 hours, provide tailored solutions and accurate quotations, and assist you in solving water treatment problems.

FG Water Technologies not only provides genuine DuPont ion exchange resins but also offers a full range of water treatment equipment and services, including containerized water purification systems, reverse osmosis systems, and ultrafiltration membrane modules. It can customize the most suitable water treatment solutions according to the actual needs of enterprises, helping enterprises achieve efficient, economical, and stable water treatment operations.