Electrodeionization (EDI) Stack Modules: Essential for Water Treatment Systems

Now, let’s shift gears to the fascinating world of water treatment with Electrodeionization (EDI) Stack Modules. These devices are critical for producing high-purity water in various industries, including pharmaceuticals, power plants, and semiconductor manufacturing.

EDI systems are designed to efficiently remove ions from water, replacing traditional ion-exchange processes with a continuous method that eliminates the need for chemical regeneration. This makes them highly efficient and environmentally friendly.

Types of EDI Modules

EDI modules are available in two main structural forms: Plate-Frame and Spiral-Wound. Both designs serve distinct purposes in water treatment, based on the needs of the operation.

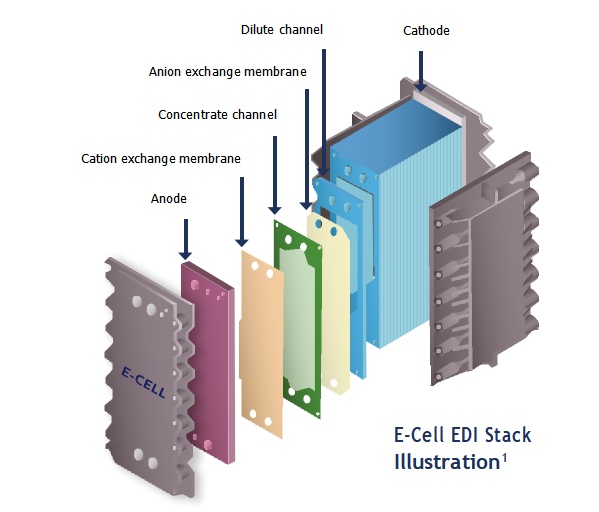

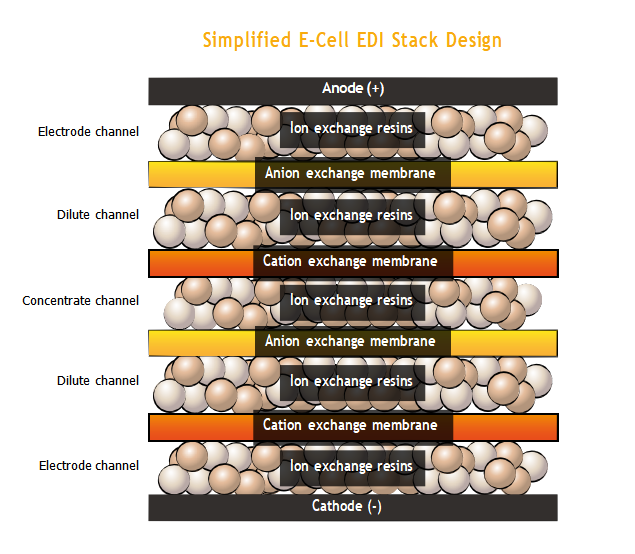

1. Plate-Frame EDI Modules

These modules are composed of positive and negative electrode plates, ion-exchange membranes, and baffles. They are typically rectangular or circular and come in different sizes, depending on the required water production volume.

Advantages:

Robust and durable design.

Easy to repair or replace individual modules.

Scalable to meet growing production needs.

2. Spiral-Wound EDI Modules

Spiral EDI modules feature a roll configuration, where layers of positive and negative membranes, freshwater baffles, and concentrated water baffles are stacked and then rolled into a spiral shape. The concentrated water distribution pipe also functions as the negative electrode in this design.

Advantages:

Compact and efficient design.

Higher efficiency due to reduced resistance.

Suitable for high-volume applications.

Operation Modes of EDI Modules

EDI modules come with two primary modes of operation: Concentrate Direct Discharge and Concentrate Circulation. The choice of mode impacts the system's energy efficiency and its ability to handle varying water quality.

1. Concentrate Direct Discharge EDI Module

In this mode, the concentrate chamber and the pole water chamber are filled with conductive materials like ion-exchange resin, which negates the need for a concentrate circulation system. This approach offers the following benefits:

Improved Energy Efficiency: Larger currents are achieved without increasing salt content, reducing the need for excessive power.

Adaptability: Can handle variations in inlet water quality without significant performance drops.

2. Concentrate Circulation EDI Module

This system circulates concentrate water through the module to optimize the desalination process. It continuously reintroduces concentrate into the system to maintain high current levels and reduce the risk of scaling.

Advantages:

Enhanced Efficiency: Higher current levels are sustained, improving water purification rates.

Reduced Scaling: Circulating concentrate helps avoid the buildup of salts and minerals on the membranes.

Increased Durability: Continuous circulation keeps the membranes cleaner for longer periods.

Advantages of EDI Modules in Industrial Water Treatment

Higher Purity Water Production: EDI modules provide a continuous method of deionization, producing ultra-pure water without the need for chemicals.

Environmentally Friendly: Unlike traditional methods that require chemical regeneration, EDI systems eliminate chemical waste, making them a greener option.

Cost-Effective: The reduction in chemical usage, along with the long lifespan of EDI modules, results in lower operational costs.

Modular Design: EDI systems can be scaled to meet varying water production needs, making them suitable for a wide range of industries.

Why Choose Our Electrodeionization EDI Stack Modules?

FG Water Technologies offers high-quality Electrodeionization EDI Stack Modules with a focus on long-lasting performance, efficiency, and environmental sustainability. Whether you’re in the pharmaceutical, power, or semiconductor industry, our EDI systems will meet your water treatment requirements.

Key Features:

Low energy consumption.

High desalination efficiency.

Modular design for easy repair and scalability.

Available in both Plate-Frame and Spiral-Wound types.

For more information, visit our product page: Electrodeionization EDI Stack Module

Contact Us

Ready to take your event to the next level with Inflatable Arches and Advertising Inflatables or interested in learning more about EDI Stack Modules? Reach out to us today!

Contact Us: Contact Page

Email: [email protected]

Our team is ready to assist you with all your inquiries and provide expert advice on choosing the right solution for your needs.