Activated Carbon Filter Tank 4074 17-23T/H Industrial RO System for Food/Beverage Conductivity <10us/cm@25℃

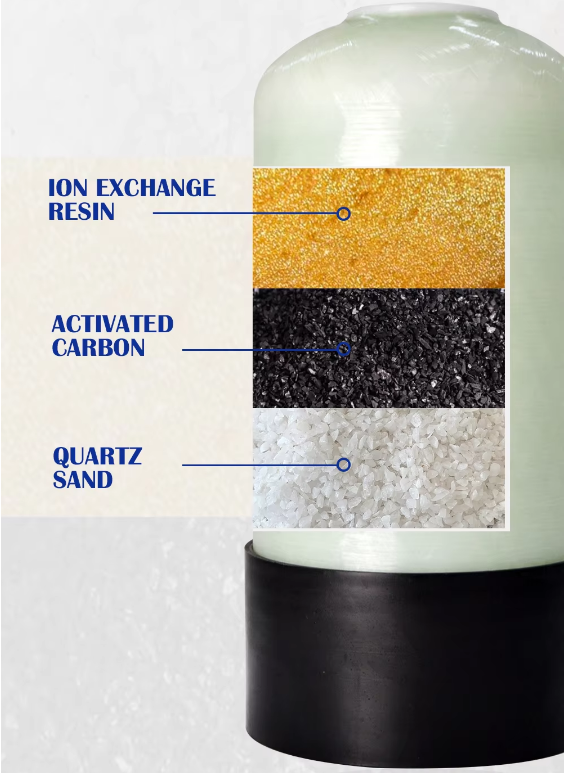

In the field of industrial water treatment, the activated carbon filter tank, as a core component of the industrial reverse osmosis (RO) system, has become the ideal choice for mineral water, direct drinking water, beverage, and food processing industries due to its excellent adsorption performance and stable operation efficiency.

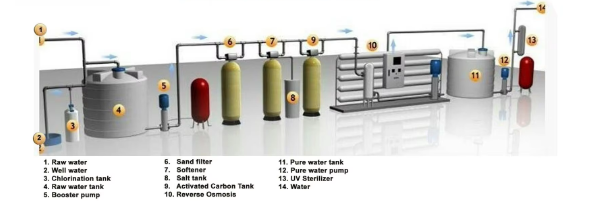

The system adopts a scientific process design: The raw water pump provides power, and the water flows through the sand filter to remove large particles of impurities, then enters the activated carbon filter tank for deep purification. Through the porous structure of activated carbon, it efficiently adsorbs organic matter, odors, residual chlorine, etc., laying a solid foundation for subsequent treatment. Subsequently, the water softener reduces water hardness, the cartridge filter intercepts tiny particles, and finally, the high-pressure pump delivers the water to the reverse osmosis membrane module to achieve deep purification of water quality.

The core parameters of the activated carbon filter tank highlight its industrial-grade strength: It has an imperial size of 4074, a tank diameter and height of φ1000×1900mm, and a top opening with 4" thread for easy maintenance. The design flow rate is stable at 17.0~23.0T/H, and with the system's production capacity of 25m³/h, it can meet the needs of medium and large-scale industrial production. The effluent water quality meets strict standards: the conductivity is <10us/cm at 25℃, and it supports parameter customization to meet different needs.

Industrial application case: A large juice processing plant once faced the problem that the odor of raw water affected product flavor. After introducing this system, the activated carbon filter tank efficiently removed phenolic substances and odors in the water. Combined with the deep purification of the reverse osmosis system, the effluent water quality was stably up to standard. The taste of the produced juice was improved by 30%, and due to the stable operation of the system, the equipment failure rate was reduced by 25%, with the annual production capacity increased to 90,000 tons, significantly reducing production costs.

Whether it is the standard production capacity of 25m³/h or the customizable effluent index (conductivity <10us/cm@25℃), this system can accurately match the diversified needs of industrial production. Choose this activated carbon filter tank to inject stable and efficient water treatment power into your production process.

Size(inch) | Diam&Height(mm) | Opening(inch) | Design Flow Rate(T/H) |

4074 | φ1000×1900 | Top Opening 4" Thread | 17.0~23.0 |