DHP 19 Axial Piston Pumps(High Pressure Pump For Industrial Reverse Osmosis)

The DHP 19 Axial Piston Pump is a High Pressure Pump For Industrial Reverse Osmosis developed by Wuxi Fenigal Science and Technology Co., Ltd. in collaboration with its OEM partner, Shenzhen CW Environment Technology. Specifically designed for conveying high-pressure, large-flow, low-viscosity corrosive fluids in industrial reverse osmosis systems, it serves as a core power equipment for medium-to-large-scale scenarios such as seawater desalination, industrial wastewater zero-liquid discharge, and high-purity raw material liquid concentration.

As a key member of Fenigal’s DHP series, the DHP 19 inherits the brand’s core positioning of "breaking foreign technological monopolies and realizing domestic substitution" since it launched the R&D of high-pressure plunger pumps in 1990. Since the initial R&D stage, Fenigal has aimed to address pain points of traditional plunger pumps such as "oil leakage pollution, poor corrosion resistance, and high operation & maintenance costs", and the DHP 19 has achieved comprehensive optimizations in these aspects: Based on the axial piston principle, it realizes high-pressure fluid conveyance through the reciprocating motion of plungers parallel to the drive shaft within plunger bores, which creates volume changes. Its core technical highlight lies in the "fluid self-lubrication design"—using the conveyed liquid as the lubricating medium, it completely eliminates the lubricating oil tank of traditional plunger pumps, fundamentally preventing oil leakage from contaminating reverse osmosis media. This makes it particularly suitable for membrane concentration processes in the food and pharmaceutical industries that have strict requirements on medium purity (such as juice concentration and purification of traditional Chinese medicine extracts). Meanwhile, the DHP 19 is integrated with a flush check valve, which forces one-way fluid flow when the pump is stopped, preventing medium backflow from damaging pump body seals and reverse osmosis membrane elements, and greatly improving the operational safety of the system.

In terms of materials and performance, the key components of the DHP 19 are made of 2205 duplex stainless steel (SAF 2205 / EN 1.4462 / UNS 31803), providing excellent resistance to high salt and strong corrosion. It can withstand corrosive fluids such as seawater, desulfurization wastewater from coal-fired power plants, and high-salt chemical wastewater for a long time. During operation, through the optimized arrangement of multiple plungers, the pulsation amplitude is controlled to be much lower than that of centrifugal pumps, with noise ≤85 dB(A), making it suitable for scenarios sensitive to operating noise such as municipal water supply stations and food workshops. Its compact structure allows direct installation on motors or internal combustion engines without occupying additional large space, making it applicable to space-constrained scenarios such as coastal factories and island desalination stations.

In terms of application scenarios, as a High Pressure Pump For Industrial Reverse Osmosis, the DHP 19 is widely used in three core fields: (1) Large-scale seawater and brackish water desalination systems in coastal cities and industrial parks, providing stable high-pressure power for municipal water supply and industrial production; (2) Industrial wastewater zero-liquid discharge treatment, such as desalination and salt concentration of printing and dyeing, chemical wastewater, helping enterprises achieve water resource recycling and environmental compliance; (3) Membrane concentration processes for raw material liquids in the food and pharmaceutical industries, meeting high hygiene standards and medium purity requirements. Its technical level and product quality have reached the world’s advanced level, and it can stably meet the long-term operation needs of various medium-to-large-scale industrial reverse osmosis systems.

The technical parameters of the DHP 19 high-pressure plunger pump cover key indicators such as geometric displacement, flow rate, pressure, rotation speed, power, and temperature adaptability, which are the core basis for system selection, equipment matching, and energy consumption calculation. The specific parameters are shown in the table below:

| Technical Parameter Item | Value/Specification |

|---|

| Product Model | DHP 19 |

| Geometric Displacement | 219 cm³/rev |

| Flow Rate at Rated Speed (1500 rpm) | 18.8 m³/h |

| Minimum Outlet Pressure | 20 Bar (Contact the manufacturer for adjustment if needed) |

| Maximum Continuous Outlet Pressure | 80 Bar |

| Minimum Inlet Pressure | 2 Bar |

| Maximum Continuous Inlet Pressure | 5 Bar |

| Maximum Continuous Rotation Speed | 1500 rpm |

| Minimum Continuous Rotation Speed | 700 rpm |

| Noise Level (per EN ISO 3744-2010) | ≤85 dB(A) (Measured at maximum pressure and rotation speed of the entire pump unit) |

| Power at 1500 rpm and 80 Bar | 55 kW |

| Medium Temperature | 2~50℃ (Depends on NaCl concentration) |

| Ambient Temperature | 0~50℃ |

| Equipment Weight | 78 kg |

| Integrated Function | Flush Check Valve (Standard) |

As a fixed-displacement axial piston pump, the flow rate of the DHP 19 has a strictly proportional relationship with the input shaft rotation speed (the flow rate/rotation speed ratio is fixed). The flow rate required by the system under different working conditions can be flexibly matched by adjusting the motor rotation speed. If the actual flow rate required by the system is known, the corresponding motor rotation speed can be accurately calculated using the following formula to maximize the pump operation efficiency:

Selected Motor Rotation Speed (r/min) = (Required Flow Rate (m³/h) × Rated Rotation Speed (1500 r/min)) / Rated Flow Rate (18.8 m³/h)

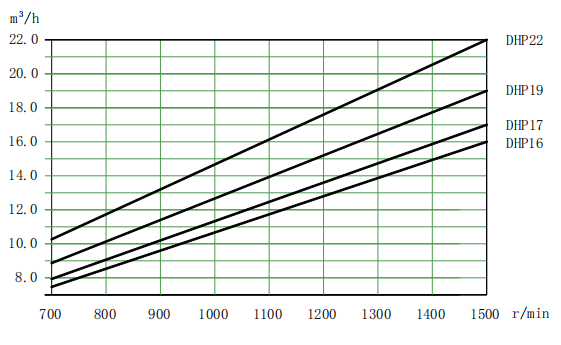

The figure below shows the flow rate-rotation speed curve of the DHP 19 at 80 Bar pressure, which allows for an intuitive view of the actual flow rate corresponding to different rotation speeds (e.g., approximately 8.8 m³/h at 700 rpm, approximately 15.0 m³/h at 1200 rpm, and the rated 18.8 m³/h at 1500 rpm). It provides a visual reference for system rotation speed matching, frequency conversion motor selection, and flow rate adjustment:

As a High Pressure Pump For Industrial Reverse Osmosis, the DHP 19 must be installed and operated in strict accordance with specifications to ensure stable system operation, extend the pump’s service life, and avoid safety risks. The core points are as follows:

Filtration Requirements: Since reverse osmosis media (such as seawater and high-salt wastewater) may contain tiny particle impurities, a depth filter with an accuracy of 10 μm (absolute accuracy) must be installed at the inlet of the DHP 19. It is required to have a filtration efficiency of 99.98% for particles larger than 10 μm (β10>5000). The precision clearance between the plunger and plunger sleeve inside the pump is extremely small (to control internal leakage and improve operation efficiency); if particles enter, they will cause rapid component wear, seal failure, and even pump body failure. The use of bag filters with only 90% efficiency is prohibited; spiral-wound filter elements are recommended to ensure filtration effectiveness.

Pressure Control: A low-pressure control switch (set to 1 Bar) must be installed at the inlet to automatically shut down the pump when the inlet pressure is lower than 1 Bar, preventing cavitation from damaging the plunger and seals. A high-pressure control switch (set to 70 Bar) must be installed between the outlet and the reverse osmosis membrane to shut down the pump immediately when the pressure exceeds the limit. At the same time, a safety valve conforming to the specifications in Chapter 10 of the document must be installed to avoid damage to membrane elements or pipelines caused by instantaneous high pressure after the pump starts.

Pre-Startup Preparation: Before startup, thoroughly flush the pipelines and system to remove residual welding slag, debris, etc.; discharge the air from the pump and system through the pump body exhaust valve to prevent cavitation; confirm that the pump rotation direction is consistent with the arrow on the pump body. Starting the pump with the outlet valve closed is strictly prohibited (as it may cause frequent operation of the safety valve, pump body overpressure, or pipeline burst).

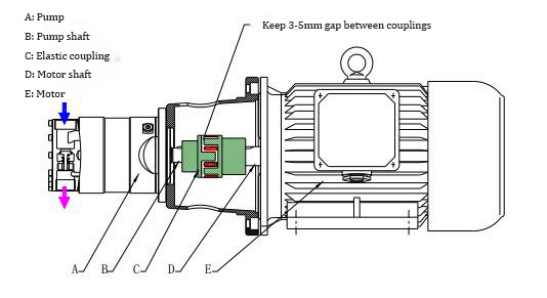

The figure below shows the standard connection method between the DHP series high-pressure pump and the motor. When installing the DHP 19, ensure that the coupling clearance is at least 3-5 mm and that there is no axial/radial load on the pump shaft to avoid bearing wear, seal leakage, or motor overload caused by misalignment:

The power consumption of the DHP 19 changes with the operating pressure. The power values at different typical pressures directly affect motor selection and system energy consumption calculation. The table below shows the power parameters of the DHP 19 at different pressures, which can be used as the core basis for motor matching (e.g., matching a 55 kW motor can meet the rated operation requirements at 80 Bar and avoid faults caused by motor overload):

| Pump Model | Rated Flow Rate (L/min) | Rated Flow Rate (m³/h) | Power at 60 Bar | Power at 70 Bar | Power at 80 Bar | Rated Rotation Speed (rpm) |

|---|

| DHP 19 | 313 | 18.8 | 45 kW | 45 kW | 55 kW | 1500 |

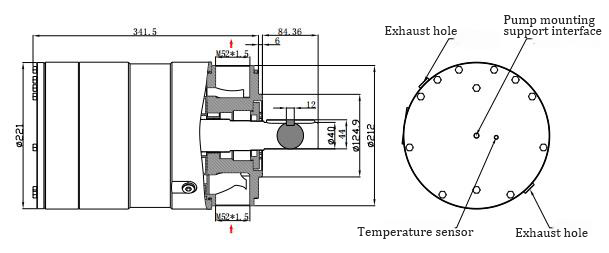

The outline dimensions of the DHP 19 (especially the inlet and outlet interface dimensions) and the installation dimensions of the complete equipment (including the frequency conversion motor) are the key basis for pipeline connection design, on-site layout planning, and equipment foundation construction. The details are as follows:

Interface Dimensions: Both the inlet and outlet of the DHP 19 feature M52×1.5 threads with a depth of 21 mm. High-pressure pipe fittings of the corresponding specifications (refer to the "High-Pressure Hose Connector" specifications in Chapter 11 of the document) must be matched to ensure the sealing performance of the interface and avoid safety risks and efficiency losses caused by high-pressure fluid leakage.

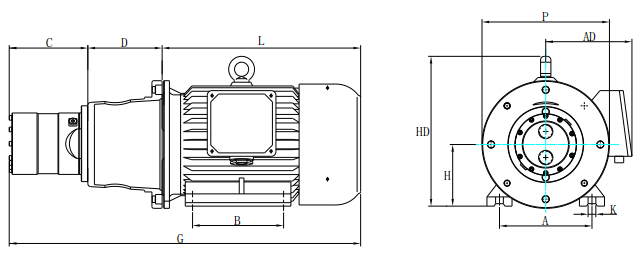

Complete Equipment Dimensions: When the DHP 19 is equipped with an independent fan motor (frequency conversion motor), the installation dimensions corresponding to motors of different powers are shown in the table below (Unit: mm), which can be used for on-site space planning, equipment fixing design, and surrounding pipeline arrangement:

| Pump Model | A | B | H | K | P | AD | HD | C | D | L | G | IEC Motor |

|---|

| DHP 19 | 318 | 305 | 200 | 19 | 400 | 305 | 505 | 342 | 234 | 760 | 1336 | 37 kW -4P |

| DHP 19 | 356 | 286 | 225 | 19 | 450 | 325 | 550 | 342 | 234 | 785 | 1136 | 45 kW -4P |

| DHP 19 | 356 | 311 | 225 | 19 | 450 | 325 | 550 | 342 | 275 | 865 | 1482 | 55 kW -4P |

| DHP 19 | 406 | 349 | 250 | 24 | 550 | 380 | 630 | 342 | 275 | 945 | 1521 | 75 kW -4P |

The figure below is the outline structure diagram of the DHP 19, clearly marking the positions of key components such as the inlet, outlet, installation interface, exhaust hole, and temperature sensor interface, facilitating quick positioning and pipeline connection by on-site installers:

Although the DHP 19 adopts a self-lubricating design (no lubricating oil required), proper maintenance can significantly extend the equipment’s service life (designed for over 8000 hours of operation) and reduce operation & maintenance costs. The core maintenance points are as follows:

Daily Maintenance: During operation, real-time monitoring of the pump’s noise, vibration, and inlet/outlet pressure is required. If there is a sudden increase in noise, intensified vibration, or abnormal pressure fluctuations, the pump must be shut down immediately for inspection to check for plunger wear, seal aging, or inlet filter blockage. When operating in a high-salt environment (such as seawater desalination), the pump cavity must be flushed with fresh water after each shutdown to discharge residual concentrated brine and prevent salt crystallization from damaging the plunger and seals—during flushing, the pump can be started briefly (10-20 seconds) to ensure complete discharge of residual brine in the pump cavity.

Shutdown Maintenance: For short-term shutdowns (≤3 days), no flushing is required; the pump only needs to be kept filled with the medium. For medium-term shutdowns (3~15 days), the pump cavity and inlet/outlet pipelines must be thoroughly flushed with fresh water. For long-term shutdowns (>15 days), the pump must be flushed with fresh water containing food-grade bactericide to prevent microbial growth from causing component corrosion. After flushing, the pump inlet and outlet must be sealed to prevent impurities from entering.

Regular Inspection: A comprehensive disassembly and inspection is recommended after 8000 hours of operation. Worn parts (such as seal plates, plunger sleeves, and springs) should be replaced. At the same time, check the tightness of the check valve and the wear of the inlet/outlet interface threads, and replace the sealing gasket in a timely manner to ensure no internal leakage or high-pressure leakage risks.

Fenigal provides comprehensive warranty and maintenance services for the DHP 19, covering the full-life-cycle usage needs of the equipment. The specific service contents are shown in the table below:

| Service Type | Service Content | Remarks |

|---|

| Free Warranty | 1-year free maintenance from the date of ex-factory (excluding damage caused by human error or improper use); 8000-hour maintenance-free warranty (not exceeding 18 months from the production date) | It is required to meet the conditions of "specified filtration accuracy (10 μm), operating pressure (≤80 Bar), and rotation speed (≤1500 rpm)" |

| Fault Handling | Axial piston pump fault detection, on-site maintenance (such as seal replacement and pressure switch debugging), and factory repair (such as plunger repair and pump cavity cleaning) | A response will be provided within 24 hours after receiving a fault report, prioritizing the resolution of shutdown issues in industrial reverse osmosis systems to reduce production losses |

| Spare Parts and Customization Services | Provision of original spare parts (such as M52 interface check valves, 2205 stainless steel plungers, and seal plates); customization of corrosion-resistant components according to customers' special medium requirements | Spare parts are made of the same materials as the original to ensure full compatibility with the DHP 19, and no system re-commissioning is required after replacement |

| Maintenance for Similar Pumps | Provision of maintenance services for axial piston high-pressure pumps of other domestic and international brands | Covering common high-pressure pump models in the industrial reverse osmosis field, reducing the maintenance cost and management difficulty of customers' multi-brand equipment |

For maintenance or warranty inquiries, please contact Wuxi Fenigal Science and Technology for professional support: