Chemical Pickling Filter Tank 4096 18-25T/H 6'' Flange Multi-Filter Functions

Chemical pickling filter tank is a versatile player in the industrial water treatment field. It integrates multiple filtering functions, can accurately deal with complex water quality, and provides stable pretreatment support for pickling processes in chemical, metallurgical, electroplating and other industries, ensuring the efficient operation of subsequent production links.

Core Parameter Analysis

This chemical pickling filter tank has an imperial size of 4096, with a tank diameter and height of φ1000×2400mm. It adopts a Top&Bottom Opening 6" Flange design, which is convenient for filling and replacing large filter materials and has excellent sealing performance. Its Design Flow Rate is 18.0~25.0T/H, which can meet the continuous water demand of medium and large industrial production lines.

Size(inch) | Diam&Height(mm) | Opening(inch) | Design Flow Rate(T/H) |

4096 | φ1000×2400 | Top&Bottom Opening 6" Flange | 18.0~25.0 |

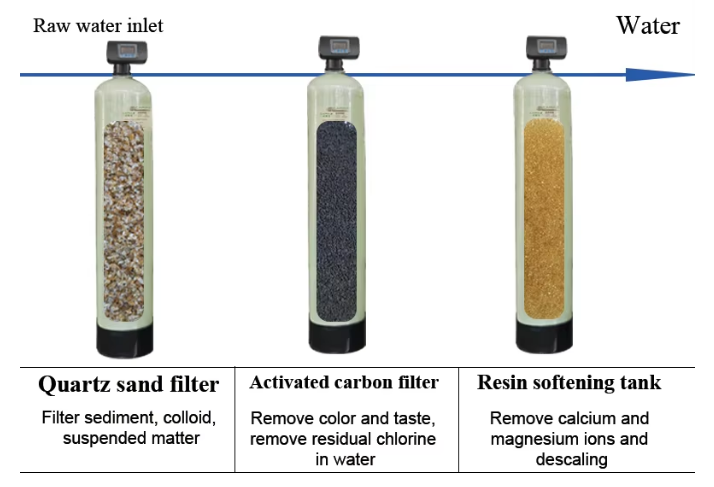

Core Filtering Functions of the Product

Quartz sand filter: As the first line of defense in pretreatment, it can efficiently remove solid particles, suspended solids, colloids and sediments in water, significantly reducing the turbidity of water and laying a foundation for subsequent filtration.

Activated carbon filter: Focuses on removing color, odor and residual chlorine in water. After treatment, the residual chlorine content in water can be reduced to ≤0.1PPM. It also adsorbs organic matter and colloids, reducing pollution to subsequent systems (such as reverse osmosis, ultrafiltration, etc.).

Manganese sand filter: Has a long service life, is efficient and energy-saving, and is specially designed to remove iron, manganese ions and yellowing in well water and river water, avoiding corrosion to equipment and impact on human health caused by long-term use of water with excessive iron and manganese.

Resin softening tank: With the help of ion exchange resin, it removes harmful substances such as hardness ions and metal ions in water, softens water quality, improves the overall water treatment efficiency, and protects subsequent equipment from scaling.

Industrial Application Case

A large electroplating factory's pickling process once had frequent failure of the solution in the pickling tank due to excessive impurities in raw water, with monthly solution replacement cost exceeding 100,000 yuan, and the product qualification rate was only 85%. After introducing the chemical pickling filter tank, through the synergistic effect of four-stage filtration, the turbidity of raw water decreased from 20NTU to below 1NTU, residual chlorine was completely removed, and iron and manganese contents met the standards. The treated water is used in the pickling process, the service life of the solution is extended to 3 months, saving 70,000 yuan per month. The product qualification rate is increased to 98%, with annual income increasing by 5 million yuan.