R8040-600PSI RO FRP Pressure Vessel - High Temperature Resistant Multi-Field Use

Wuxi Fenigal Science and Technology Co., Ltd. has been supplying RO FRP pressure vessels for water industry products since 2010. After over ten years of development, the factory owns self-developed multi-axis rotating wire winding machines, which greatly enhance product strength and surface flatness, and has established five self-developed curing, grinding and pressure testing systems. Currently, it produces 100,000 FRP membrane shells annually, satisfying domestic and foreign customers with reliable products and perfect services.

Our Mission

Provide high-quality products to meet the personalized needs of customers

To guarantee product quality, a scientific and perfect quality assurance system has been set up; from design and development to after-sales service, quality assurance is integrated into every process with a rigorous professional attitude, offering customers products with reliable performance and superior quality.

Standard production procedure of RO pressure vessel: Winding → Sanding → Lathing → Drilling → Hydro test → Painting → Package

Standard inspection and test plan of RO pressure vessel: The pressure vessels are inspected in line with industrial standards. The main inspection contents in production include:

Production raw materials:

Fiberglass

Epoxy Resin

Anhydride

Production process test

Hydro-static pressure test (every vessel): Increase pressure at a constant speed, maintain for 3 minutes at 1.1 times working pressure, ensuring no leakage and the pressure gauge remains at the original pressure

Final Inspection

Application fields: Electronics, electricity, metallurgy, chemical industry, medicine, food and beverage, industrial sewage and wastewater, water reuse, brackish water, sub-seawater, seawater desalination and other fields.

Product features:

●Sulfuric acid resistance: 25%

●Hydrofluoric acid resistance: 10%

●High temperature resistance: 60/90°℃

●Fully adaptable to special media environments like strong acid, strong alkali, electroplating solution, chlor-alkali solution, concentrated solution, garbage leachate, etc.

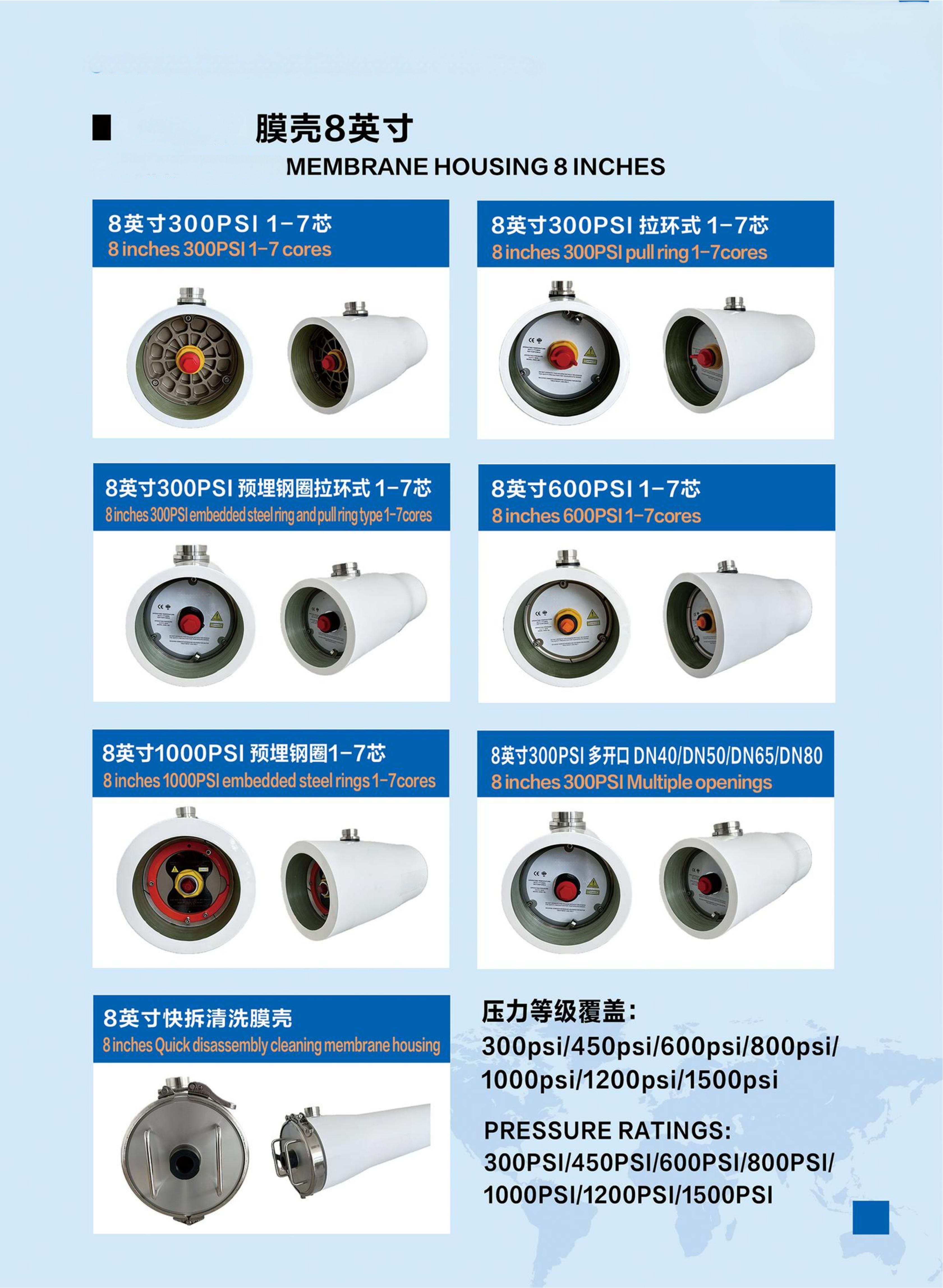

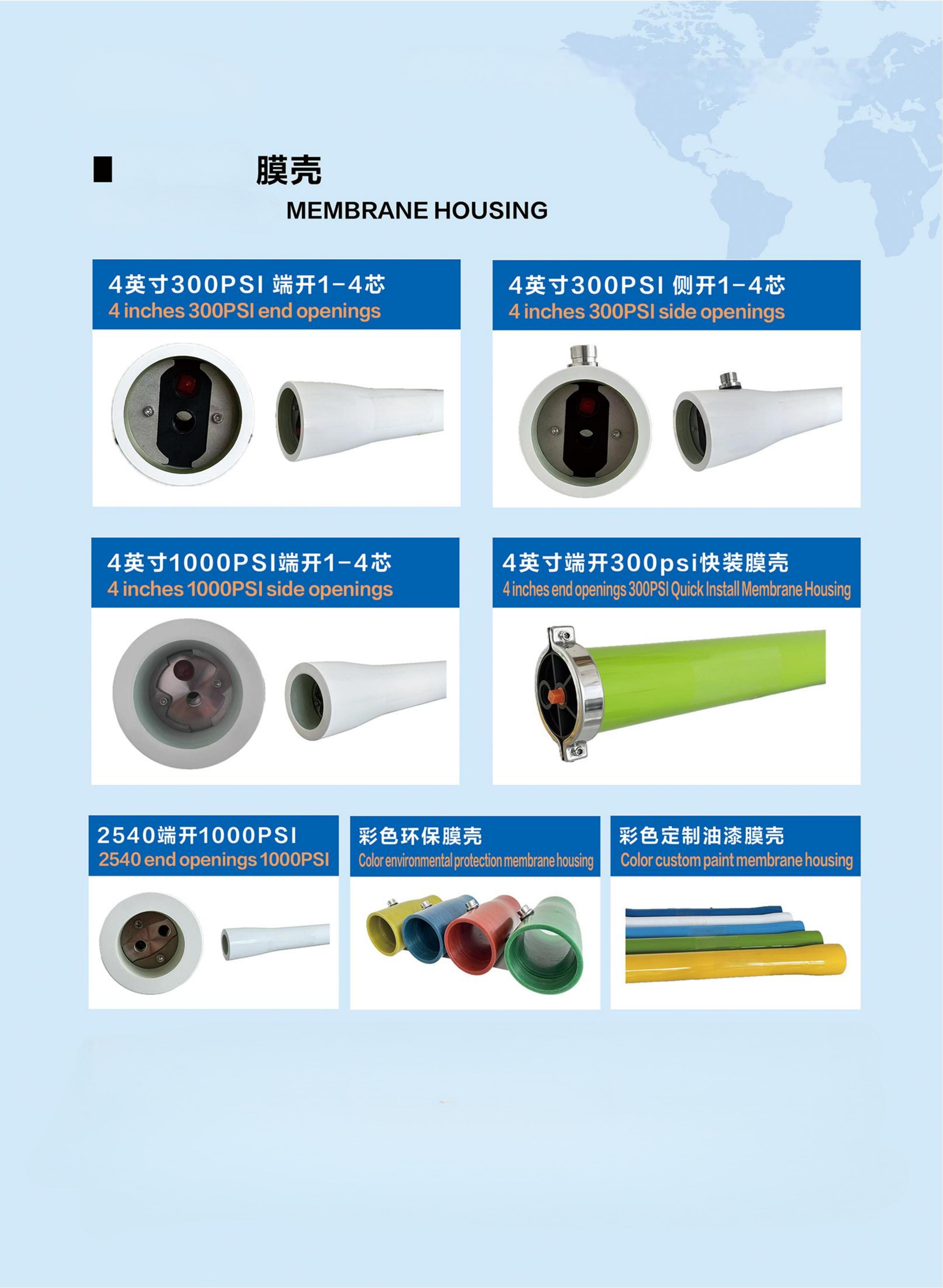

Pressure level coverage: 300psi/450psi/600psi/800psi/1000psi/1200psi/1500psi

PRESSURE RATINGS: 300PSI/450PSI/600PSI/800PSI/1000PSI/1200PSI/1500PSI

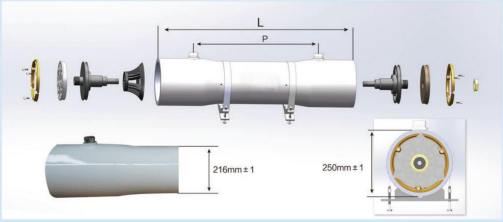

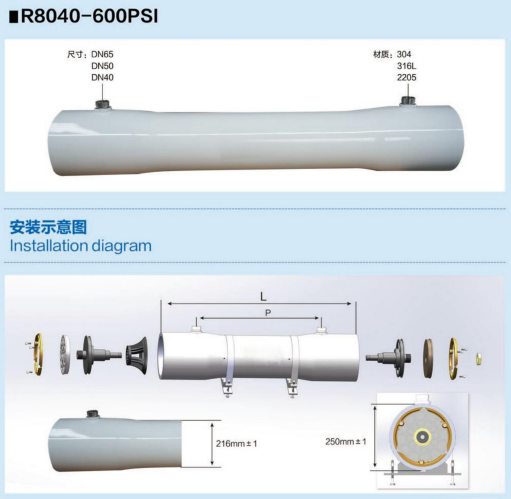

R8040-600PSI

Main installation dimensions

Working Pressure | Element(s) | L(mm) | P(mm) |

600PSI | 1 | 1459 | 1139 |

600PSI | 2 | 2475 | 2155 |

600PSI | 3 | 3491 | 3171 |

600PSI | 4 | 4510 | 4190 |

600PSI | 5 | 5526 | 5206 |

600PSI | 6 | 6542 | 6222 |

600PSI | 7 | 7558 | 7238 |