LC PURE Laboratory MINI-300 EDI Module A Powerful Ultra-pure Water Supply Unit for Large-scale Experimental Scenarios

In the high-intensity experimental operations of large laboratories, the continuous and stable supply of ultra-pure water is a core element to ensure experimental efficiency and result accuracy. The LC PURE Laboratory MINI-300 EDI module, with its strong water production capacity and reliable performance, has become a capable assistant in such scenarios.

The core operation mechanism of the MINI-300 EDI module is the synergy of electrodialysis and ion exchange technologies. The internal mixed ion exchange resins are responsible for adsorbing cations and anions in water, while the electrodes at both ends of the module provide a transverse DC electric field, driving the adsorbed ions through the corresponding anion and cation exchange membranes.

A fresh water chamber is formed between the anion exchange membrane facing the positive electrode and the cation exchange membrane facing the negative electrode, and a concentrated water chamber is formed between the anion membrane facing the negative electrode and the cation membrane facing the positive electrode. When water flows through these chambers, ions in the fresh water chamber are continuously removed, gradually improving the water purity, and the concentrated water chamber collects and discharges the removed ions. Through the efficient combination of 10 membrane pairs, the MINI-300 realizes the continuous production of ultra-pure water, meeting the high water demand of large-scale experimental scenarios.

| Parameter Category | Specific Value |

|---|

| Standard water production flow (L/h) | 300 |

| Maximum water production flow (L/h) | 320 |

| Minimum water production flow (L/h) | 280 |

| Operating voltage (VDC) | 0-80 |

| Operating current (0-6A) | 2.5 |

| Number of membrane pairs | 10 |

| Operating net weight (KG) | 14 |

| Maximum power (KW/H) | 0.5 |

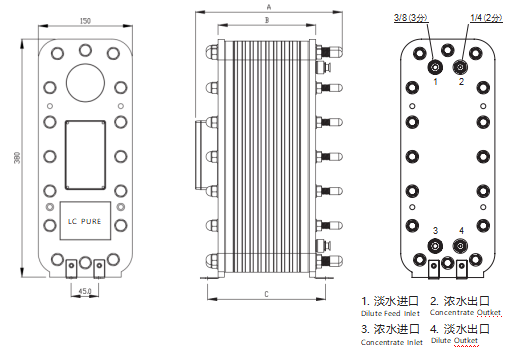

| Fresh water inlet/outlet | 3/8" PE pipe |

| Concentrated water inlet/outlet | 1/4" PE pipe |

| Center length A (mm) | 253 |

| Total length B (mm) | 183 |

| Front-back positioning length C (mm) | 218 |

| Overall height (mm) | 380 |

| Overall width (mm) | 150 |

| Left-right positioning (mm) | 45 |

To ensure the stable operation and prolong the service life of the MINI-300, the inlet water must meet the following conditions:

It must be reverse osmosis (RO) product water, with an inlet conductivity of less than 10μs/cm (including CO₂ and silicon). Controlling it within 5μs/cm can further reduce losses.

The temperature should be maintained at 5-30℃, and the inlet water pressure should be kept at 0.1-0.3MPa.

The maximum total chlorine content (Cl₂) is <0.02ppm, and iron (Fe), manganese (Mn), and sulfide (S⁻) are all <0.01ppm.

The pH value is between 7-8, and the total hardness (calculated as CaCO₃), dissolved organic matter (TOC, calculated as C), and silicon (calculated as SiSO₂) are all <0.5ppm.

Oxidizing substances and oil/grease must not be detected.

A laboratory of an environmental monitoring center needs to conduct a large number of water quality sample analyses every day, requiring 280L of ultra-pure water and a resistivity of ≥15MΩ·cm. The previously used equipment often had supply interruptions during peak water production, and water quality fluctuations led to poor repeatability of some testing items.

After introducing the MINI-300, the laboratory has achieved:

A stable daily water production of 300L, ensuring supply even during peak hours of experimental water use, completely solving the problem of supply interruptions.

The water resistivity is stable at 17-18MΩ·cm, and the relative standard deviation (RSD) of test data has decreased from 8% to 3%, significantly improving the reliability of results.

No manual acid-base regeneration is needed, only 1 simple inspection per month, saving the operation and maintenance time of 2 technical personnel.

The concentrated water is recycled for laboratory floor cleaning and equipment cooling, saving about 4 tons of water per month.

High water production capacity: The standard water production flow of 300L/h is suitable for the high water demand of large laboratories, and can be maximally increased to 320L/h to cope with temporary water peaks.

Stability and reliability: The configuration of 10 membrane pairs ensures stable water production quality, reducing experimental errors caused by water quality fluctuations.

Space-saving: With a width of 150mm, it does not occupy too much laboratory space while providing large water production.

Economic and environmental protection: No need to treat acid and alkali wastewater, and concentrated water can be reused, reducing operating costs and environmental burdens.

With its strong water production capacity and stable performance, the LC PURE Laboratory MINI-300 EDI module provides an efficient and reliable ultra-pure water solution for large-scale experimental scenarios, facilitating the efficient progress of experimental work.