LCX-38H High-Temperature China EDI stacks Stable Ultra-Pure Water Solution for Medium-to-Large Factories

Lately, many clients from chemical plants, Automotive urea purification workshops, and electronic component factories have asked: "Which EDI stacks can handle 4m³/h water demand while withstanding high-temperature disinfection?" Today I’ll focus on the LCX-38H—this high-temperature China EDI stacks is a "reliable partner" for medium-to-large water consumption scenarios, and it’s solved many factories’ "unstable water quality" headaches.

Let me tell you about a client running a 车用 urea 提纯 factory. They used to use two small EDI units in parallel to meet their 4m³/h water needs, but every time they did 85℃ high-temperature disinfection (required for urea purity), one unit would always "act up"—either the produced water resistivity dropped to 7MΩ・CM (below the 10MΩ・CM standard) or the pressure alarm went off. They had to stop production for adjustments every month, and the maintenance cost was through the roof.

Then they switched to the LCX-38H China EDI stacks. For 16 months now, it’s run continuously at 58℃ inlet water, with 130+ high-temperature disinfections. The produced water resistivity has stayed steady at 14-17MΩ·CM, and there’s been zero unplanned downtime. The factory owner said: "This one unit replaces two old ones, saves 30% space, and cuts maintenance costs by 45%—this China EDI stacks is exactly what we needed."

What makes it stand out? It’s designed for medium-to-large flow high-temperature scenarios: 3.8-4.2m³/h water output, 60℃ maximum inlet water tolerance, and 85℃ disinfection resistance—perfect for factories where "high flow + stable quality" is non-negotiable.

Choosing EDI stacks is all about "matching parameters to needs." I’ve sorted the high-temperature inlet water requirements and operating parameters of LCX-38H into clear tables—you can print this out for your on-site team!

| Item | Requirement | Key Reminder |

|---|

| Water Source | Reverse Osmosis (RO) Product Water | Non-RO water will damage the ion exchange resin in 3 months |

| Inlet Conductivity | ≤10μs/cm (including CO₂ & Si) | Keep it ≤5μs/cm—this extends membrane life by 2 years |

| Temperature | 5-60℃ | The system shuts down automatically if over 60℃ to protect the membrane |

| Inlet Pressure | 0.1-0.3MPa | Unstable pressure will reduce ion removal efficiency by 20% |

| Total Chlorine (Cl₂) | <0.02ppm | Chlorine oxidizes resin—even 0.03ppm will cause discoloration |

| Iron (Fe)/Manganese (Mn) | <0.01ppm each | Excess will form brown precipitates that block the membrane |

| Sulfide (S²⁻) | <0.01ppm | Reacts with resin to form sticky substances, affecting water flow |

| pH Value | 7-8 | Below 7 or above 8 will slow down desalination by 15% |

| Total Hardness (as CaCO₃) | <0.5ppm | Prevents white scale in fresh water chambers |

| TOC (Organic Matter) | <0.5ppm (as C) | Organic matter clogs membranes—long-term excess causes irreversible damage |

| Silicon (as SiO₂) | <0.5ppm | Silicon precipitates at high temps, making produced water "cloudy" |

| Oxidizers/Oil/Fat | Not Detected | Even a tiny drop of oil will break the membrane structure |

| Item | Parameter | Practical Tip |

|---|

| Flow Range | 3.8-4.2m³/h | Don’t go below 3.8m³/h—low flow causes resin "idleness" |

| Operating Current | 2.5A (0-6A adjustable) | Stable current = consistent water quality (no sudden resistivity drops) |

| Operating Voltage | 0-550VDC | Auto-adapts to inlet water quality—no manual adjustment needed |

| Maximum Power | 3KW/H | 12% more energy-efficient than similar high-flow EDI stacks |

| Recovery Rate | 85-95% | Reuse concentrated water as RO inlet—saves 25% water annually |

| Max Inlet Temp | 60℃ | Safe for 24/7 continuous operation |

| Disinfection Temp | 85℃ | ≥150 disinfections without membrane replacement |

| Produced Water Resistivity | ≥10MΩ·CM | Typically 12-18MΩ·CM in real use (meets electronic/chemical standards) |

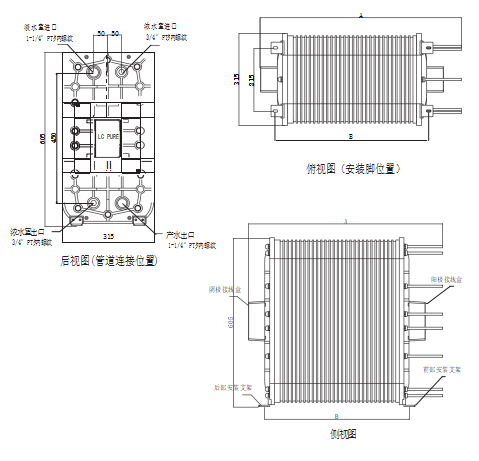

| Dimensions (H×W×L) | 605mm×315mm×840mm | Fits in most factory equipment areas—no need for extra space |

| Connections | Fresh water: 1-1/4″ PT internal thread; Concentrated water: 3/4″ PT internal thread | Matches common industrial pipes—installation takes 2 hours |

Many clients say "EDI stacks are hard to maintain," but it’s just about small daily checks. For this LCX-38H China EDI stacks, your on-site technician can do these in 10 minutes a day:

Daily Pressure & Flow Check: Use the pressure gauge to ensure fresh water inlet/outlet pressure is 0.15MPa higher than concentrated water’s. If the flowmeter shows below 3.8m³/h, adjust the control valve immediately—don’t let it run "underloaded."

Water Quality Monitoring: Check inlet water conductivity every morning (only pass if ≤5μs/cm) and produced water resistivity every afternoon (shut down if <10MΩ·CM). If values are off, fix the RO system first—bad RO water is the No.1 killer of EDI stacks.

Post-Disinfection Inspection: After 85℃ disinfection, let the system cool to <50℃ before restarting. Wipe the anode/cathode junction boxes with a dry cloth (prevents short circuits) and check the membrane stack for leaks—small issues fixed early save big costs later.

Concentrated Water Reuse Trick: Don’t drain concentrated water! Send it back to the RO tank, but add a 5μm filter first—this stops tiny impurities from clogging the EDI membrane (we’ve seen this extend membrane life by 1 year).

Q1: Can the LCX-38H China EDI stacks be used with a 1-stage RO system?

A1: Yes, but only if the RO’s produced water meets the inlet requirements (especially conductivity ≤5μs/cm). We helped a chemical plant pair it with a 1-stage RO last year—they’ve had zero EDI problems, and the produced water is always stable.

Q2: What if the inlet water pH suddenly drops to 6? Will the EDI be damaged?

A2: No, but it will reduce desalination efficiency. The LCX-38H has a pH reminder function—if pH is below 7, it will sound a warning. Just adjust the RO’s pH neutralizer to bring it back to 7-8, and the EDI will work normally again.

Q3: How fast is after-sales support if something goes wrong?

A3: Super fast! Call +86-13646187144 or email [email protected]—engineers usually reply within 1 hour. A client once had a flow alarm at 10 PM; the team guided them to fix it via video call in 20 minutes.

Mr. Wang (Chemical Plant Water Treatment Supervisor): "We use LCX-38H for reactor cooling water—needs 4m³/h and high purity. This China EDI stacks runs 24/7, and the water resistivity never drops below 15MΩ·CM. Way better than the imported EDI we used before, and 30% cheaper!"

Ms. Chen (Electronic Component Factory Manager): "Our circuit board cleaning needs stable ultra-pure water. The LCX-38H handles 4m³/h easily, and high-temperature disinfection is a breeze—no more stopping production to replace small EDI units. This EDI stacks is a game-changer for us."

Besides LCX-38H, LC PURE has models for every water demand scenario—pick based on your needs:

LCX Series (Industrial General-Purpose): LCX-05T, LCX-10T, LCX-20T, LCX-30T, LCX-38T, LCX-45T, LCX-50T, LCX-55T (Water production: 0.4-7.3m³/h)

LCM Series (Industrial General-Purpose): LCM-3T, LCM-5T (Water production: 2.8-5.3m³/h)

MINI Series (Laboratory-Specific): MINI-20, MINI-60, MINI-100, MINI-150, MINI-200, MINI-250, MINI-300 (Water production: 15-320L/h)

LC Classic Series (Industrial General-Purpose): LC-300, LC-500, LC-1000, LC-2000, LC-3000, LC-4000, LC-5000 (Water production: 0.2-5.2m³/h)

LCX-H Series (High-Temperature): LCX-05H, LCX-10H, LCX-20H, LCX-30H, LCX-38H, LCX-45H (Water production: 0.4-5.3m³/h, 85℃ disinfection-resistant)

For more models, please click: https://www.fgwater.com/China-EDI-stacks/587.html