LCX-20H High-Temperature China EDI Stacks A Complete Guide to Parameters Cases and Maintenance

Recently, many customers in the pharmaceutical, electronics, and vehicle urea purification industries have asked me: what EDI stacks should I choose for high-temperature scenarios? Today, I will focus on a highly practical one - the LCX-20H high-temperature China EDI stacks, which has performed beyond expectations in scenarios requiring frequent high-temperature disinfection.

Let me start with a real case: a biopharmaceutical factory previously used ordinary EDI membrane stacks. Every time it conducted 85°C high-temperature disinfection in accordance with GMP requirements, either the quality of the produced water fluctuated or the service life of the membrane stacks was drastically reduced. It had to replace the membrane stacks twice a year, resulting in extremely high costs. Later, it switched to the LCX-20H China EDI stacks. After 18 consecutive months of use and more than 160 disinfections, the resistivity of the produced water remained stable at 12-15 MΩ·CM, fully meeting the requirements for water for injection, and the maintenance cost was reduced by nearly 40%.

Why is it so durable? The core lies in its design specifically for high-temperature scenarios. It can withstand inlet water at 60°C for a long time and also resist high-frequency disinfection at 85°C. In industries with high hygiene requirements such as pharmaceuticals and food, it is simply a "must-have" EDI stacks.

No matter which EDI stacks you choose, parameters are hard indicators. I have compiled the high-temperature inlet water requirements and operation parameters of LCX-20H into tables for your easier reference:

| Item | Requirement Standard | Remarks |

|---|

| Inlet Water Source | Reverse Osmosis (RO) Product Water | Non-RO product water will severely damage the membrane stack |

| Inlet Water Conductivity | ≤10μs/cm (including CO₂ and silicon) | It is recommended to be ≤5μs/cm for longer service life |

| Temperature | 5-60°C | Exceeding the range will trigger protective shutdown |

| Inlet Water Pressure | 0.1-0.3MPa | Unstable pressure will affect ion migration efficiency |

| Maximum Total Chlorine (Cl₂) | <0.02ppm | Chlorine will oxidize ion exchange resins |

| Iron (Fe)/Manganese (Mn) | Each <0.01ppm | Exceeding the standard will form precipitates and block the membrane |

| Sulfide (S²⁻) | <0.01ppm | To avoid reaction with resins |

| pH Value | 7-8 | Deviation will reduce desalination efficiency |

| Total Hardness (calculated as CaCO₃) | <0.5ppm | To prevent scaling and blocking the fresh water chamber |

| Dissolved Organic Matter (TOC) | <0.5ppm (calculated as C) | To avoid organic matter contaminating the membrane and resins |

| Silicon (calculated as SiO₂) | <0.5ppm | Silicon is prone to precipitation at high temperatures, affecting produced water |

| Oxidizing Substances/Oil/Fat | Not Detected | Any residue will damage the membrane structure |

| Item | Parameter Value | Description |

|---|

| Flow Range | 1.8-2.3m³/h | Can be fine-tuned according to water demand, not less than 1.8m³/h |

| Operating Current | 2.5A (0-6A adjustable) | Stable current ensures more uniform desalination efficiency |

| Operating Voltage | 0-340VDC | Automatically adapts to inlet water quality without manual adjustment |

| Maximum Power | 2KW/H | Saves about 15% energy compared with ordinary high-temperature EDI |

| Recovery Rate | 85-95% | Concentrated water can be reused for RO inlet to save water |

| Maximum Inlet Water Temperature | 60°C | Stable threshold for long-term operation |

| Disinfection Temperature | 85°C | Disinfection frequency ≥150 times, no membrane replacement required |

| Produced Water Quality | ≥10MΩ·CM | Usually 12-18 MΩ·CM in actual operation |

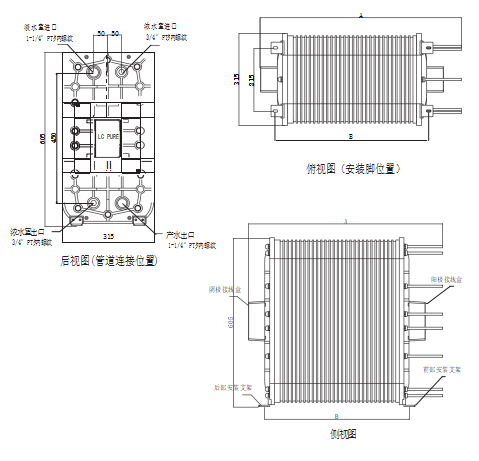

| Overall Dimensions (Height × Width × Total Length) | 605mm×315mm×560mm | Small floor space, can be installed in the corner of the workshop |

| Inlet/Outlet Connections | Fresh water: 1-1/4″PT internal thread; Concentrated water: 3/4″PT internal thread | Compatible with common industrial pipelines for easy installation |

Many customers say "EDI stacks are difficult to maintain", but in fact, they just haven't found the right method. For the LCX-20H China EDI stacks, I have summarized 5 simple maintenance tips that electricians can master after reading once:

Monitor pressure and flow regularly: Use a pressure gauge to check the pressure at the fresh water inlet and outlet, which should be about 0.15MPa higher than that at the concentrated water inlet and outlet; use a flowmeter to monitor the fresh water flow, which should not be lower than 1.8m³/h. If there is a deviation, adjust the control valve to prevent the membrane stack from "underload" or "overload".

Never stop water quality monitoring: Check the inlet water with a conductivity meter every day (only qualified if ≤5μs/cm) and the produced water with a resistance meter (shut down if lower than 10MΩ·CM). If the standard is exceeded, first check the RO system to prevent bad water from entering the membrane stack.

Inspect after high-temperature disinfection: After each 85°C disinfection, cool down to below 50°C before starting the machine. At the same time, check if the membrane stack has leakage and if the anode/cathode junction boxes are damp to avoid short circuits.

Tips for reusing concentrated water: Do not discharge concentrated water directly; instead, reuse it in the RO inlet tank. However, a 5μm filter should be added to prevent impurities from blocking the membrane.

Do not ignore power maintenance: It is recommended to use "one-to-one" DC power control. In case of alarms such as low flow or high pressure, cut off the power first and then troubleshoot, and do not operate with faults.

Q1: Can the LCX-20H China EDI stacks be used in parallel with other types of EDI?

A1: Absolutely! For example, two LCX-20H units in parallel can produce 3.6-4.6m³/h of water, meeting higher water demand. However, it is important to use the automatic control mode to ensure uniform inlet water flow and pressure for each membrane stack, avoiding overload of some membrane stacks.

Q2: If the inlet water conductivity occasionally exceeds 5μs/cm, will it break immediately?

A2: An occasional exceedance is not a big problem, but it should not last more than 30 minutes! Long-term exceedance of 10μs/cm will cause "overload" of ion exchange resins, reduce desalination efficiency, and shorten the service life of the membrane stack. Therefore, you must keep a close eye on the quality of RO product water.

Q3: Is the after-sales response for LCX-20H fast?

A3: The after-sales service of the manufacturer is very timely. If you have any problems, call +86-13646187144 or send an email to [email protected]. Generally, a solution will be provided within 2 hours. For example, a customer once had a pressure alarm, and the engineer solved it in 10 minutes through remote guidance.

Engineer Wang (Water Treatment Supervisor of an Electronics Factory): "We use it for semiconductor wafer cleaning, which requires high-temperature pure water. The LCX-20H EDI stacks is so worry-free. It can resume water production soon after high-temperature disinfection, and the water quality is stable. It is nearly half cheaper than the imported membrane stacks we used before, with excellent cost-effectiveness!"

Manager Liu (Vehicle Urea Purification Factory): "I was worried that the purity of the produced water would be insufficient at high temperatures. But after using the LCX-20H, I found that not only does the purity meet the standard, but also the reused concentrated water saves a lot of water. We saved more than 20,000 yuan in water fees a year. This China EDI stacks is a perfect choice!"

In addition to the LCX-20H, LC PURE has many EDI stacks suitable for different scenarios. You can choose according to water consumption and temperature requirements:

LCX Series (Industrial General-Purpose): LCX-05T, LCX-10T, LCX-20T, LCX-30T, LCX-38T, LCX-45T, LCX-50T, LCX-55T (Water production: 0.4-7.3m³/h)

LCM Series (Industrial General-Purpose): LCM-3T, LCM-5T (Water production: 2.8-5.3m³/h)

MINI Series (Laboratory-Specific): MINI-20, MINI-60, MINI-100, MINI-150, MINI-200, MINI-250, MINI-300 (Water production: 15-320L/h)

LC Classic Series (Industrial General-Purpose): LC-300, LC-500, LC-1000, LC-2000, LC-3000, LC-4000, LC-5000 (Water production: 0.2-5.2m³/h)

LCX-H Series (High-Temperature Type): LCX-05H, LCX-10H, LCX-20H, LCX-30H, LCX-38H, LCX-45H (Water production: 0.4-5.3m³/h, resistant to 85°C disinfection)

For more models, please click: https://www.fgwater.com/China-EDI-stacks/587.html