Introduction of Linear Reinforced Polyvinylidene Fluoride Hollow Fiber Membrane Module (MBR Membrane)

Enhanced polyvinylidene fluoride hollow fiber membrane module (MBR membrane)

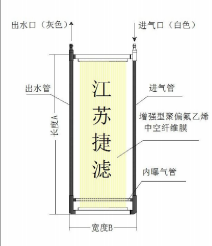

Lined reinforced polyvinylidene fluoride hollow fiber membrane curtain modules (MBR membranes) are the membrane separation components and core components of membrane bioreactors (MBRs). Our company's lined reinforced polyvinylidene fluoride hollow fiber membrane curtain modules (MBR membranes) feature advanced structure and excellent performance, and have been patented (Patent No.: ZL201120106252.4). They primarily consist of reinforced polyvinylidene fluoride hollow fiber membranes, an air inlet pipe, an internal aeration pipe, and an outlet pipe.

The water outlet is a thickened polyvinyl chloride (UPVC) lining of a reinforced polyvinylidene fluoride (PVDF) hollow fiber membrane curtain module (MBR membrane). During installation, the outlet is connected to the water collection pipe via a quick-release connector and a transparent hose. The water inlet is the through-hole of the reinforced polyvinylidene fluoride hollow fiber membrane curtain module (MBR membrane). During installation, the airport connects to the internal aeration main via a quick-release connector and a transparent hose.

Enhanced polyvinylidene fluoride hollow fiber membrane module (MBR membrane)

The water outlet is a thickened polyvinyl chloride (UPVC) lining of a reinforced polyvinylidene fluoride (PVDF) hollow fiber membrane curtain module (MBR membrane). During installation, the outlet is connected to the water collection pipe via a quick-release connector and a transparent hose. The water inlet is the through-hole of the reinforced polyvinylidene fluoride hollow fiber membrane curtain module (MBR membrane). During installation, the airport connects to the internal aeration main via a quick-release connector and a transparent hose.

Lined reinforced polyvinylidene fluoride hollow fiber membrane module (MBR membrane) has unique internal air flow structure (patented technology)

The PVDF curtain wall membrane produced by Fenigal features an internal lining consisting of an air inlet duct, a drain duct, an internal vent duct, and a reinforced inner lining. Composed of PVDF hollow fiber membranes, the internal vent duct significantly improves the membrane's air cleaning performance and promotes stable operation.

Ultra-high strength

The lined reinforced PVDF hollow fiber membrane utilizes a unique support layer manufacturing technology. The membrane's tensile and compressive strengths are significantly higher than those of PVDF hollow fiber membranes produced using NIPS (non-solvent phase separation) and TIPS (thermal phase separation). This is more vividly described as a "damage-free hollow fiber membrane." Most importantly, Fenigal's lined PVDF hollow fiber membrane eliminates the problem of membrane surface shedding.

Good anti-pollution and antioxidant properties

This patented membrane manufacturing technology results in an extremely smooth surface for the hollow fiber membrane, significantly improving its anti-fouling properties. The highly crystalline polyvinylidene fluoride used in the membrane manufacturing process significantly improves the membrane's antioxidant properties and cleaning recovery capabilities.

Permanent hydrophilicity

The ribbed reinforced polyvinylidene fluoride (PVDF) hollow fiber membrane produced by "Fenigal" is added with a hydrophilic polymer substance with excellent compatibility and unique cross-linking technology, so that the hydrophilic properties of the membrane can be permanently retained and the flow rate of the membrane is more stable.

Reinforced polyvinylidene fluoride hollow fiber membrane module (MBR membrane) with liner

ModelName:JL-MBR-N-CO-PVDF

JL——Fenigal Membrane Code

N——membrane area

CO-PVDF——Reinforced PVDF with lining Material

Example:Example:JL-MBR-10-CO-PVDF:Fenigal-10 square meters of PVDF - lined MBR membrane

Performance parameters of reinforced polyvinylidene fluoride hollow fiber curtain membrane module (MBR membrane) with lining

| Membrane module model | JL-MBR-8-CO-PVDF | JL-MBR-10-CO-PVDF | JL-MBR-15-CO-PVDF |

| Component parameters | PVDF material (woven fiber lining reinforcement) - NIPS process |

|

| Effective membrane area (㎡) | 8 | 10 | 15 |

| Average pore size (μm) | 0.05

|

| Patented component design | In-membrane flotation anti-fouling enhanced design |

| Component size | Total length × total width (mm) | 1050 X 645 | 1550 X 645 | 1550 X645 |

| Number of membrane filaments | Number of roots | 1600 | 1200 | 1800 |

| Interface size | Two-terminal socket (DN) | 32

|

| Component Connection | PE hose(mm) | 14

|

| Conditions of Use | Filter method | Negative pressure suction filtration |

| Maximum transmembrane pressure difference(MPa) | -0.08

|

| Applicable temperature range(℃) | 5~45 |

| Long-term tolerancepH range | 2~13 |

| Average ventilation volume of the component (Nm³/h) | 3-5

| 4-6 | 6-9 |

| Recommended sludge concentration (MLSS) | 6,000 to10,000 |

| Design flux at 25℃(L/㎡·h) | 14~22 |

| Recommended component operation cycle | Produces water for 8 minutes,stops for 2 minutes |

1. All technical parameters in the table are factory inspection values under standard testing conditions. 2. The water production flow rate in the table refers to the actual water production design flow rate when the product is used for MBR technology to treat sewage. |

|

(MBR membrane) liner-packed reinforced polyvinylidene fluoride hollow fiber curtain membrane module

Inner packaging

Every two linear reinforced polyvinylidene fluoride hollow fiber membrane curtain modules (MBR membranes) are wrapped and sealed with plastic bags.

outer packaging

Every two linear reinforced polyvinylidene fluoride hollow fiber curtain membrane modules (MBR membranes) are packed in a corrugated carton.

Transport linear reinforced polyvinylidene fluoride hollow fiber membrane curtain module (MBR membrane)

Note! (1) The polyvinylidene fluoride hollow fiber curtain membrane assembly (MBR membrane) and its lining should be protected from collision, extrusion, rain and sunlight exposure, freezing and mechanical damage.

Note! (2) During transportation, the maximum number of stacking reinforced polyvinylidene fluoride hollow fiber membrane modules (MBR membranes) is 10. Excessive stacking will cause irreparable damage to the MBR membranes.

Note! (3) During transportation, it is strictly prohibited to stack heavy objects on the reinforced polyvinylidene fluoride hollow fiber membrane assembly (MBR membrane) to avoid causing irreparable damage to the reinforced polyvinylidene fluoride hollow fiber membrane assembly (MBR membrane).

Storage linear reinforced polyvinylidene fluoride hollow fiber membrane module (MBR membrane)

The wire-reinforced polyvinylidene fluoride hollow fiber membrane module (MBR membrane) should be stored indoors or in a sheltered location without corrosive gas.

Cable reinforced polyvinylidene fluoride hollow fiber membrane modules (MBR membranes) should be stored within the temperature range of 5-40°C, avoiding freezing. Keep away from flammable or explosive materials and away from ignition sources.

The gasket reinforced polyvinylidene fluoride hollow fiber membrane curtain module (MBR membrane) is stored in stacks of up to 10 boxes. Stacking exceeding this height may cause irreversible damage to the gasket reinforced polyvinylidene fluoride hollow fiber membrane curtain module (MBR membrane).