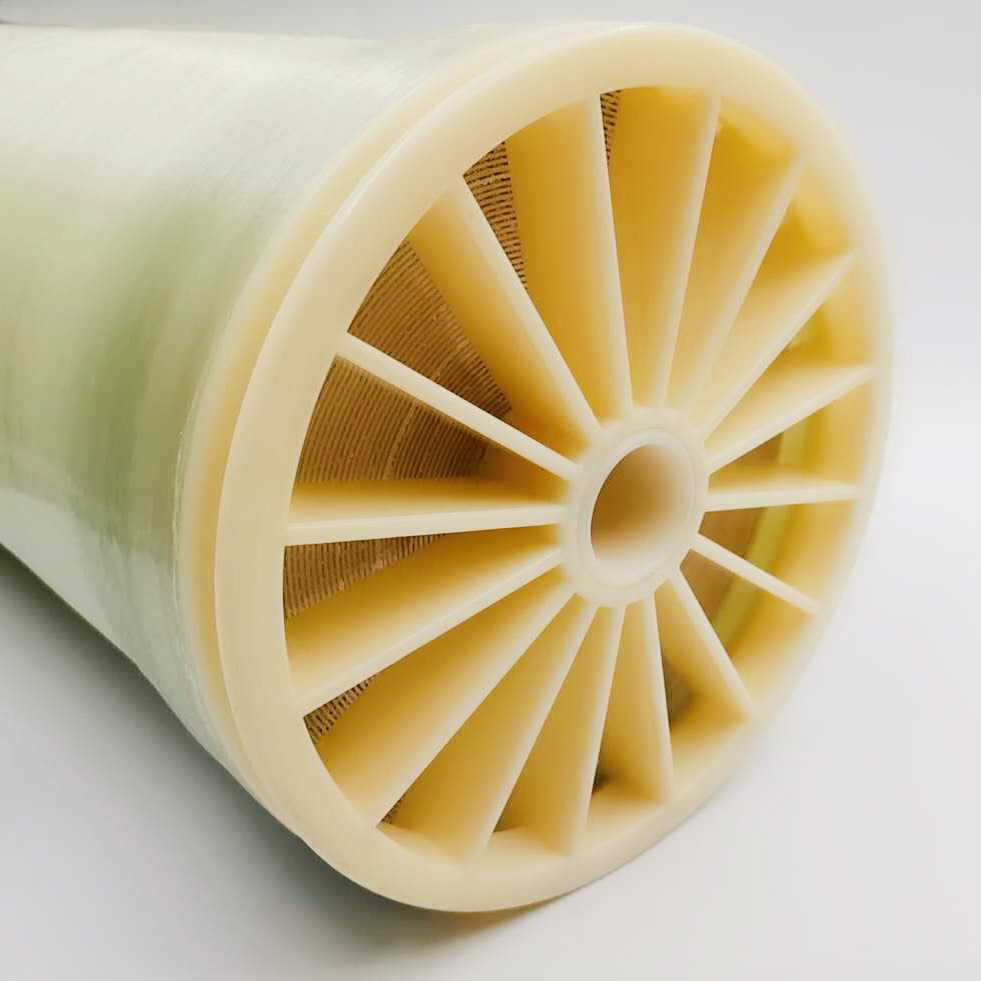

N-TECH Brackish Water RO Membranes Custom Branded Bulk Production for Industrial Municipal Use

Searching for high-performance brackish water reverse osmosis membranes that can carry your brand? N-TECH delivers. Our RO membrane elements are engineered for industrial pure water production, brackish water desalination, and reclaimed water reuse—with the flexibility to batch-produce under your brand name.

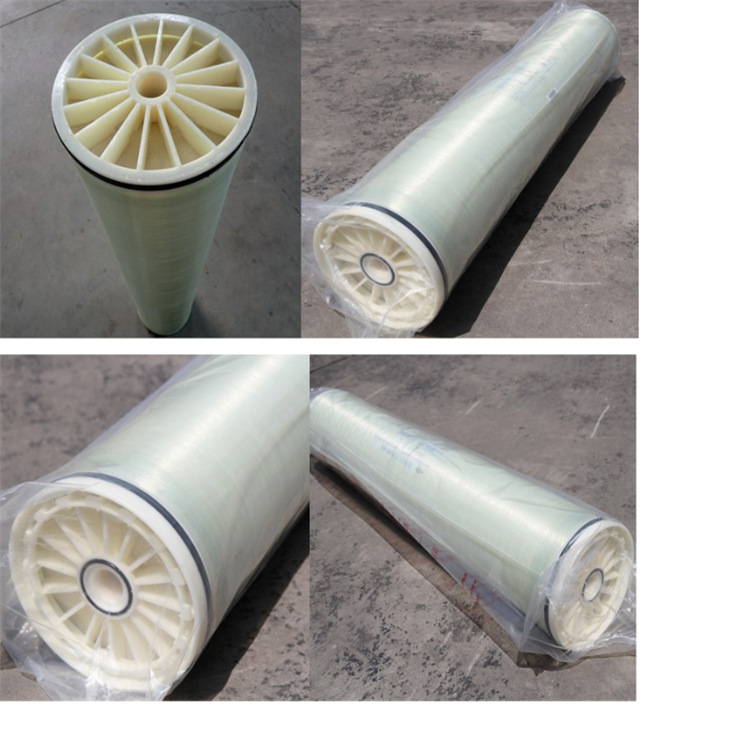

Crafted via world-leading composite coating tech and fully automated lines, every membrane guarantees consistent quality: excellent filtration, standout anti-fouling properties, and energy efficiency to keep systems running stable long-term. Available in 2.5”, 4”, and 8” diameters, they fit standard pressure vessels for easy installation.

Whether you need balanced flow, low energy use, or extra fouling resistance, our BW, LE, XLP, and FR series meet diverse raw water needs. And with bulk production options featuring your logo and branding, we help strengthen your market presence.

Your Brand, Our Quality: Add your logo, packaging, and specs to bulk orders—build brand recognition effortlessly.

Proven Performance: Up to 99.7% salt rejection, anti-fouling designs, and low-energy options cut operational costs.

Batch Consistency: Automated production ensures uniform quality across 100+ unit orders.

Tailored to You: Choose from 2.5”, 4”, 8” sizes and specialized series to match client needs.

Water Treatment Distributor, Illinois: Partnered for 300+ BW-XFR membranes branded under their name. The extra anti-fouling design reduced client maintenance by 40%, driving 2x repeat orders.

Industrial Supplier, Michigan: Ordered 500 LE series membranes with custom labels for a car factory. Low-energy operation cut the factory’s utility bills by 28%, boosting their reputation.

Municipal Contractor, Arizona: Used XLP membranes (branded as their own) for a desal project. At 100psi, they hit 99.2% rejection, meeting regulations and securing a 5-year contract.

| Product | Permeate Flow (GPD/m³/d) | Stabilized Rejection (%) | Min Rejection (%) | Membrane Area (ft²/m²) | Feed Spacer (mil) |

|---|

| BW-365-34 | 10500 (39.7) | 99.6 | 99.4 | 365 (34) | 34 |

| BW 400 | 11000 (41.6) | 99.6 | 99.4 | 400 (37) | 28 |

| BW 440 | 12650 (47.9) | 99.6 | 99.4 | 440 (41) | 28 |

| BW 400-34 | 11000 (41.6) | 99.6 | 99.4 | 400 (37) | 34 |

| Product | Permeate Flow (GPD/m³/d) | Stabilized Rejection (%) | Min Rejection (%) | Membrane Area (ft²/m²) | Feed Spacer (mil) |

|---|

| BW-FR 365-34 | 10500 (39.7) | 99.6 | 99.4 | 365 (34) | 34 |

| BW-FR 400-34 | 11000 (41.6) | 99.6 | 99.4 | 400 (37) | 34 |

| BW-FR 400-LD | 11000 (41.6) | 99.6 | 99.4 | 400 (37) | 34-LD |

| BW-XFR 400-34 | 11500 (43.5) | 99.7 | 99.45 | 400 (37) | 34 |

| BW-XFR 400-LD | 11500 (43.5) | 99.7 | 99.5 | 400 (37) | 34-LD |

| Product | Permeate Flow (GPD/m³/d) | Stabilized Rejection (%) | Min Rejection (%) | Membrane Area (ft²/m²) | Feed Spacer (mil) |

|---|

| LE 400 | 11000 (41.6) | 99.5 | 99.2 | 400 (37) | 28 |

| LE 440 | 12500 (47.3) | 99.5 | 99.2 | 440 (41) | 28 |

| LE-FR 400-34 | 11000 (41.6) | 99.5 | 99.2 | 400 (37) | 34 |

| LE-FR 400-LD | 11000 (41.6) | 99.5 | 99.2 | 400 (37) | 34-LD |

| Product | Permeate Flow (GPD/m³/d) | Stabilized Rejection (%) | Min Rejection (%) | Membrane Area (ft²/m²) | Feed Spacer (mil) |

|---|

| XLP 400-34 | 13200 (50.0) | 99.2 | 98.7 | 400 (37) | 34 |

| XLP 400-LD | 13200 (50.0) | 99.2 | 98.7 | 400 (37) | 34-LD |

| XLP 440 | 14500 (54.9) | 99.2 | 98.5 | 440 (41) | 28 |