RO Membrane FRP Pressure Vessels Acid & High Temp Resistant 300PSI for Multiple Fields

Wuxi Fenigal Science and Technology Co., Ltd. has been supplying RO FRP pressure vessels for the water industry since 2010. After over a decade of development, the factory is equipped with self-developed multi-axis rotating wire winding machines, which greatly enhance product strength and surface flatness. It has also established five self-developed curing systems, grinding systems, and pressure testing systems. Currently, the factory produces 100,000 FRP membrane shells annually, meeting the needs of domestic and foreign customers with reliable products and perfect services.

Our Mission

Provide high-quality products to meet the personalized needs of customers

To ensure product quality, we have established a scientific and perfect quality assurance system. From design and development to after-sales service, we integrate quality assurance into every process with a rigorous professional attitude, providing customers with products of reliable performance and superior quality.

Standard production procedure of RO pressure vessel: Winding → Sanding → Lathing → Drilling → Hydro test → Painting → Package

Standard inspection and test plan of RO pressure vessel: Our pressure vessels are inspected in accordance with industrial standards. The main inspection contents during production include the following:

Production raw materials

Fiberglass

Epoxy Resin

Anhydride

Production process test

Hydro-static pressure test (for every vessel): Increase the pressure at a constant speed, maintain it for 3 minutes at 1.1 times the working pressure, and ensure there is no leakage and the pressure gauge remains at the original pressure.

Final Inspection

Application fields: Electronics, electricity, metallurgy, chemical industry, medicine, food and beverage, industrial sewage and wastewater treatment, water reuse, brackish water, sub-seawater, seawater desalination, etc.

Product features:

● Sulfuric acid resistance: 25%

● Hydrofluoric acid resistance: 10%

● High temperature resistance: 60/90°℃

● Fully adaptable to special media environments such as strong acid, strong alkali, electroplating solution, chlor-alkali solution, concentrated solution, garbage leachate, etc.

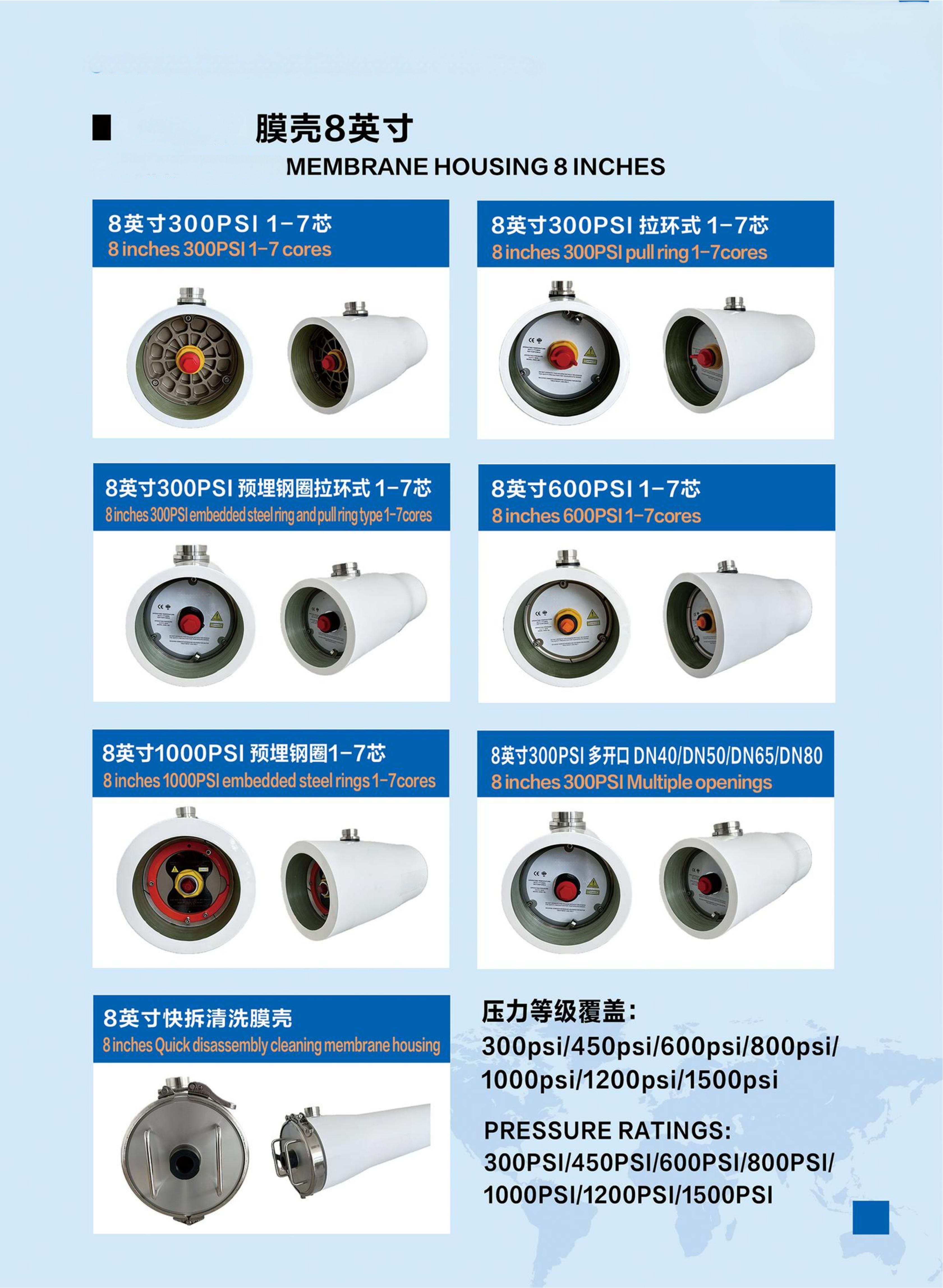

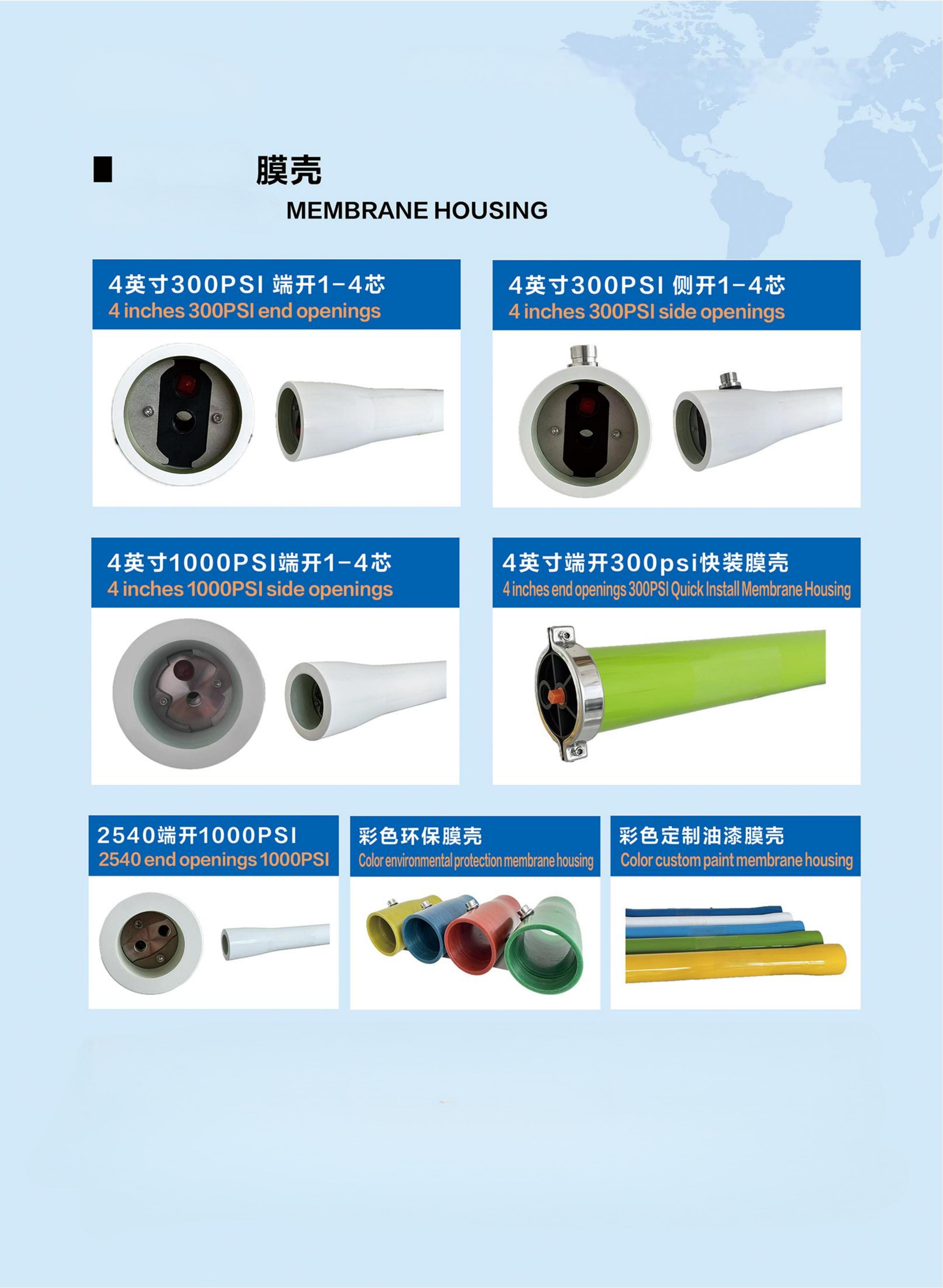

Pressure level coverage: 300psi/450psi/600psi/800psi/1000psi/1200psi/1500psi

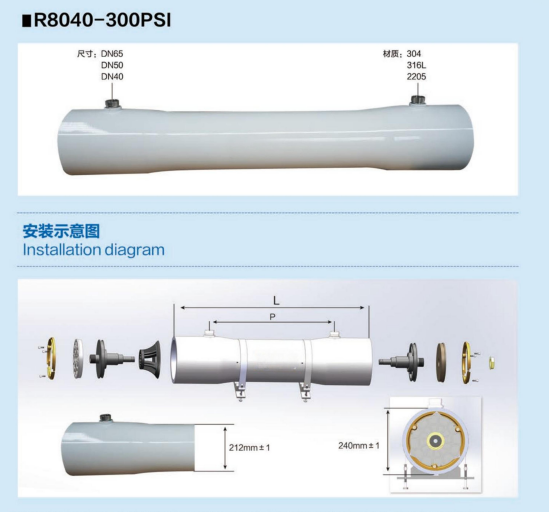

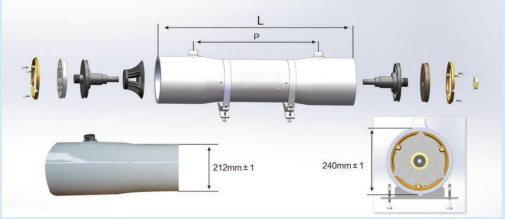

The following are the main installation dimensions of R8040-300PSI:

| Working Pressure | Element(s) | L(mm) | P(mm) |

|---|

| 300PSI | 1 | 1459 | 1139 |

| 300PSI | 2 | 2475 | 2155 |

| 300PSI | 3 | 3491 | 3171 |

| 300PSI | 4 | 4510 | 4190 |

| 300PSI | 5 | 5526 | 5206 |

| 300PSI | 6 | 6542 | 6222 |

| 300PSI | 7 | 7558 | 7238 |