DHP 2.1 Axial Piston Pump (High Pressure Pump For Industrial Reverse Osmosis)

DHP 2.1 is a core model in the DHP series of Axial Piston Pumps, suitable for small and medium-sized seawater desalination and industrial desalination systems. Specifically designed for the transportation of high-pressure, low-viscosity corrosive fluids, it can efficiently convey media such as seawater and industrial saline wastewater, and is widely used in island seawater desalination equipment and factory-level industrial wastewater desalination devices.

This pump operates based on the principle of axial piston pumps: it achieves high-pressure fluid transportation through the reciprocating movement of plungers parallel to the drive shaft in plunger bores, which changes the volume of the pump cavity. Compared with traditional piston pumps, its core advantage lies in using the transported fluid itself as the lubricating medium, eliminating the need for a lubricating oil tank and fundamentally avoiding oil leakage pollution—perfectly meeting the strict cleanliness requirements for seawater and industrial wastewater. Meanwhile, it has a compact structure (weighing only 7.8 kg), high operating efficiency, and integrates a flushing check valve, which simplifies the design of reverse osmosis membrane systems and reduces installation space and costs.

For seawater desalination and industrial desalination scenarios, DHP 2.1 has two key performance highlights:

High-Pressure Stability and Low Interference: The continuous working pressure can reach 80 Bar, meeting the high-pressure requirements of reverse osmosis systems; the pulse during operation is much smaller than that of other pump types, with low vibration and noise (≤77 dB(A) in accordance with EN ISO 3744-2010 standard), making it suitable for industrial sites sensitive to the operating environment;

Corrosion Resistance and Flexible Adjustment: Key components of the pump body are made of 2205 duplex stainless steel (SAF 2205/EN 1.4462/UNS 31803), which has excellent corrosion resistance to high-salinity media; as a fixed-displacement pump, the flow rate is strictly proportional to the rotational speed. The flow rate reaches 2.1 m³/h at the rated speed of 3000 rpm, and the motor speed can be adjusted to adapt to the water supply needs of different systems.

| Parameter Category | Specific Value |

|---|

| Product Model | DHP 2.1 |

| Geometric Displacement | 11.8 cm³/rev |

| Rated Flow at Rated Speed (3000 rpm) | 2.1 m³/h (equivalent to 35 L/min in minute flow rate) |

| Minimum Outlet Pressure | 20 Bar |

| Maximum Continuous Outlet Pressure | 80 Bar (For higher or lower pressure requirements, please contact FENIGAL sales representative) |

| Minimum Inlet Pressure | 1 Bar |

| Maximum Continuous Inlet Pressure | 5 Bar |

| Continuous Operating Speed Range | 700~3450 rpm |

| Operating Noise (EN ISO 3744-2010) | ≤77 dB(A) (measured on the entire pump unit at maximum pressure and speed) |

| Power at 3000 rpm & 80 Bar | 7.5 kW |

| Medium Temperature (depends on NaCl Concentration) | 2~50 ℃ |

| Ambient Temperature | 0~50 ℃ |

| Overall Weight | 7.8 kg |

| Integrated Component | Flushing Check Valve |

| Core Application | Small and medium-sized seawater desalination, industrial wastewater desalination and resource recovery |

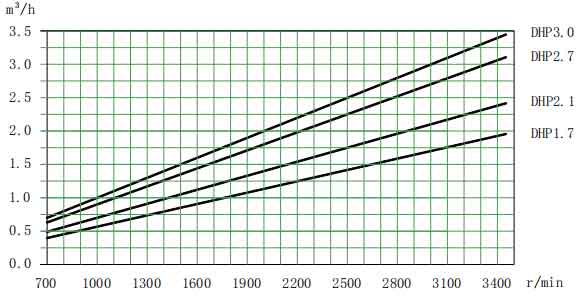

The DHP 2.1 belongs to the DHP1.7-3.0 series. At an operating pressure of 80 bar, flow rate is strictly proportional to speed (a characteristic of fixed-displacement pumps). The flow curve below provides a visual indicator of flow rate at different speeds: the horizontal axis represents speed (700-3450 rpm), and the vertical axis represents flow rate (0-3.5 m³/h). For example, at 1500 rpm, the flow rate is approximately 1.05 m³/h; at 2500 rpm, the flow rate is approximately 1.75 m³/h; and at the rated speed of 3000 rpm, the flow rate stabilizes at 2.1 m³/h.

To calculate the target speed based on actual needs, refer to the following formula:

Selected Motor Speed (r/min) = (Required Flow Rate (m³/h) × Rated Speed 3000 (r/min)) / Rated Flow Rate 2.1 (m³/h)

For instance, when an industrial desalination system requires a flow rate of 1.5 m³/h, the required rotational speed is (1.5×3000)/2.1 ≈ 2143 rpm, which is accurate and easy to calculate.

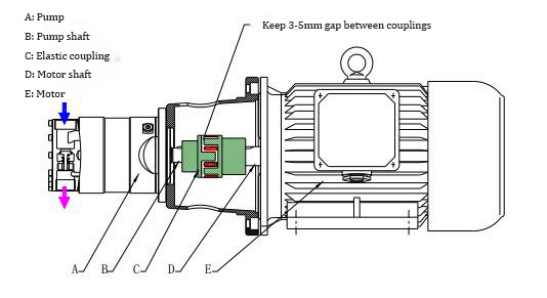

Interface Identification: The port marked "I" on the pump body is the inlet, and "O" is the outlet. The installation direction must be strictly distinguished to avoid damage to the plungers and check valves inside the pump due to reverse connection;

Motor coupling: A clearance of 3 to 5 mm must be maintained between the pump and motor couplings. The pump shaft must not be subjected to axial or radial loads (such as external forces generated by forced pipe connections) to prevent premature wear of the shaft seal and bearings. The following is a standard connection diagram for the motor and high-pressure pump, which can be used as a reference to ensure installation accuracy:

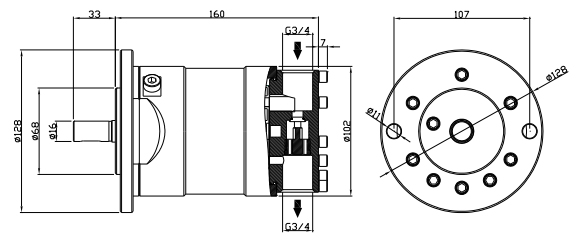

Foundation and Piping: It is recommended to install the pump unit on a base with vibration dampers to reduce vibration transmission and noise; the diameter of the inlet pipe should not be smaller than the pump inlet size (G3/4〞), and bends and joints should be minimized to reduce pressure loss (to avoid cavitation caused by insufficient inlet pressure).

Filtration Configuration: Impurity particles (such as sediment and suspended solids) in seawater and industrial wastewater can wear the precision components inside the pump. A filter with an absolute accuracy of 10 μm (filtration efficiency ≥99.98%, β10>5000) must be installed before the pump inlet. Bag filters or spiral wound filters with only 90% efficiency are strictly prohibited (prone to particle leakage, causing plunger wear);

Pressure Protection: A low-pressure control switch (set to 1 Bar) should be installed at the inlet end, which will automatically shut down the pump when the inlet pressure is lower than this value to prevent pump idling (idling is likely to cause dry friction of plungers); a high-pressure control switch (set to 70 Bar) and a safety valve (pressure adjustment range 5~9 MPa, customizable) should be installed between the pump outlet and the reverse osmosis membrane to prevent damage to the membrane module or pipeline due to system overpressure;

Start-Up, Shutdown and Flushing: In high-salinity scenarios (such as seawater desalination), the pump cavity must be flushed with fresh water after each shutdown to discharge residual concentrated brine (long-term residual concentrated brine is likely to crystallize and block the flow channel); if the shutdown lasts more than 3 days, flushing with fresh water is required; if it lasts more than 15 days, flushing with fresh water containing a bactericide is necessary (to prevent microbial growth and corrosion); starting the pump with the rear valve closed is strictly prohibited, as this may trigger the safety valve or cause pipeline burst.

The power of DHP 2.1 varies with the working pressure. Its power requirement at the rated speed of 3000 rpm is as follows:

| Pump Model | Rated Flow (L/min) | Rated Flow (m³/h) | Power at 60 Bar | Power at 70 Bar | Power at 80 Bar | Rated Speed (rpm) |

|---|

| DHP 2.1 | 35 | 2.1 | 5.5 kW | 5.5 kW | 7.5 kW | 3000 |

The working pressure of seawater desalination systems is usually 70~80 Bar, so a 7.5 kW motor is recommended to ensure stable pump operation without energy waste; for industrial desalination scenarios with lower pressure (e.g., below 60 Bar), a 5.5 kW motor can meet the requirements, effectively reducing the energy consumption cost of the system.

| Piston Pump Model | Inlet Size | Outlet Size |

|---|

| DHP 2.1 | G3/4〞, Depth 18 mm | G3/4〞, Depth 18 mm |

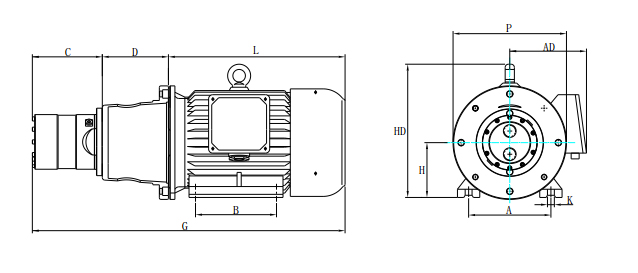

Pages 25-26 of the manual provide the overall dimension diagram of the DHP1.7~3.0 series. The following are dimensional examples of DHP 2.1 matched with commonly used motors, which can be used for planning installation space (such as the layout of machine rooms for industrial desalination equipment):

| Piston Pump | A | B | H | K | P | AD | HD | C | D | L | G | IEC Motor |

|---|

| DHP 2.1 | 216 | 140 | 132 | 12 | 300 | 220 | 350 | 165 | 155 | 520 | 840 | 5.5 kW - 2P |

| DHP 2.1 | 216 | 140 | 132 | 12 | 300 | 220 | 350 | 165 | 155 | 560 | 880 | 7.5 kW - 2P |

Lubrication Management: The transported fluid is used as the lubricating medium, so no additional lubricating oil is needed. Daily maintenance only requires judging whether to replace the filter element based on the filter pressure difference (a pressure difference exceeding 0.5 Bar indicates filter element blockage, which needs to be replaced in time to ensure clean inlet fluid);

Regular Inspection: Under standard operating conditions (10 μm filtration, normal pressure/speed), a comprehensive inspection is recommended every 8000 hours. Focus on checking the sealing performance of the shaft seal (for leakage) and the wear of plungers and plunger sleeves (excessive wear will lead to a flow rate reduction of more than 10%), and replace worn parts (such as seals and plunger sleeves) in a timely manner;

Corrosion Protection: The pump body is made of 2205 duplex stainless steel (with excellent corrosion resistance), but in high-salinity scenarios such as seawater desalination, the shutdown flushing process must be strictly implemented to avoid local corrosion (such as pitting corrosion caused by salt accumulation on the inner wall of the flow channel, which affects the pump's sealing performance) due to residual salt.

Basic Warranty: A 1-year free maintenance service is provided from the date of delivery (excluding faults caused by man-made damage or non-compliant operation, such as component wear caused by not installing a filter);

Extended Protection: If the pump operates under specified conditions at all times (meeting filtration, pressure and speed requirements), it can enjoy an 8000-hour maintenance-free warranty, with a maximum period not exceeding 18 months from the date of delivery;

After-Sales Support: The manufacturer provides fault detection, on-site maintenance, factory repair and spare parts supply services to ensure the continuous and stable operation of seawater desalination and industrial desalination systems. Support can be obtained through the contact information below.

Company: WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. (FG Water Technologies)

Address: Chuangyi Industrial Park, No. 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, P. R. China

Tel: +86-510-85163211

Mobile: +86-13646187144

Email: [email protected]

Official Website: https://www.fgwater.com

WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. (FG Water Technologies), the manufacturer of DHP 2.1, has focused on the research and development of high-pressure piston pumps since 1990 and is the first domestic enterprise to produce axial high-pressure piston pumps. After nearly 15 years of in-depth cultivation and innovation, the enterprise has realized the localization of axial high-pressure piston pumps. Its technical level and product quality have reached world advanced standards, and its production scale ranks among the top in the domestic industry, effectively solving the bottleneck problem of relying on imported products in related fields.

In collaboration with its OEM partner Shenzhen CW Environment Technology, the enterprise widely applies axial high-pressure piston pumps in fields such as seawater desalination, industrial desalination and membrane concentration. It always adheres to the tenet of "quality first, integrity-based, customer satisfaction", continuously improves the supply chain and sales service system, and is committed to providing customers with efficient core fluid equipment and technical solutions to support the implementation of the "Made in China 2025" strategy and industrial foundation strengthening strategy.

PDF manual download address:DHP type plunger pump selection manual