DHP 8.2 Axial Piston Pump (High Pressure Pump For Industrial Reverse Osmosis)

DHP 8.2 is a high-flow model in the DHP series of Axial Piston Pumps, tailored for large and medium-sized seawater desalination and industrial desalination systems. It is developed and manufactured by WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. As China’s first manufacturer of axial high-pressure piston pumps, the company has specialized in R&D of high-pressure piston pumps since 1990. After nearly 15 years of dedicated technical development, it has achieved localization of axial high-pressure piston pumps—with its technical standards and product quality reaching world-class levels. Its axial piston pumps, renowned for high corrosion resistance and large flow capacity, have become core fluid transfer equipment in industrial reverse osmosis desalination scenarios (e.g., seawater desalination plants with a daily treatment capacity of over 200 tons).

This pump operates on the axial piston pump principle: plungers parallel to the drive shaft reciprocate within plunger bores to alter the pump chamber volume, enabling high-pressure transfer of low-viscosity corrosive fluids such as seawater and industrial saline wastewater. Unlike traditional piston pumps, it uses the transferred fluid itself as a lubricant, eliminating the need for a lubricating oil tank and fundamentally preventing oil leakage contamination—fully meeting the strict cleanliness requirements of seawater desalination and industrial desalination. Additionally, it integrates a flushing check valve, which simplifies the piping design of reverse osmosis membrane systems, reduces installation space and costs, and is well-suited for industrial-grade desalination projects requiring long-term, continuous high-flow water supply.

For seawater desalination and industrial desalination applications, DHP 8.2 offers two key advantages:

Ultra-Large Flow & High Energy Efficiency: At a rated speed of 1500 rpm, it delivers a flow rate of 8.2 m³/h, meeting the high water demand of large and medium-sized desalination systems. With an operating efficiency of over 85%, it consumes only 30 kW at 80 Bar working pressure—8% to 12% less energy than traditional pumps of the same flow rate, resulting in lower long-term operating costs.

Strong Corrosion Resistance & High Reliability: Critical pump components are constructed from 2205 duplex stainless steel (SAF 2205/EN 1.4462/UNS 31803), providing excellent resistance to high-salinity media corrosion and enabling over 8000 hours of continuous operation. During operation, its pulse amplitude is ≤0.5 Bar, with low vibration and noise (≤78 dB(A) per EN ISO 3744-2010), making it ideal for industrial sites with strict requirements for equipment stability and operating environment.

| Parameter Category | Specific Value |

|---|

| Product Model | DHP 8.2 |

| Geometric Displacement | 100 cm³/rev |

| Rated Flow (at 1500 rpm) | 8.2 m³/h (136 L/min) |

| Minimum Outlet Pressure | 10 Bar |

| Maximum Continuous Outlet Pressure | 80 Bar (Contact FENIGAL sales for higher/lower pressure requirements) |

| Minimum Inlet Pressure | 2 Bar |

| Maximum Continuous Inlet Pressure | 5 Bar |

| Continuous Operating Speed Range | 700~1800 rpm |

| Operating Noise (per EN ISO 3744-2010) | ≤78 dB(A) (measured on the complete pump unit at maximum pressure and speed) |

| Power (at 1500 rpm & 80 Bar) | 30.0 kW |

| Fluid Temperature (NaCl concentration-dependent) | 2~50 ℃ |

| Ambient Temperature | 0~50 ℃ |

| Overall Weight | 34.5 kg |

| Integrated Component | Flushing Check Valve |

| Core Application | Large/medium-sized seawater desalination, industrial wastewater desalination, and resource recovery |

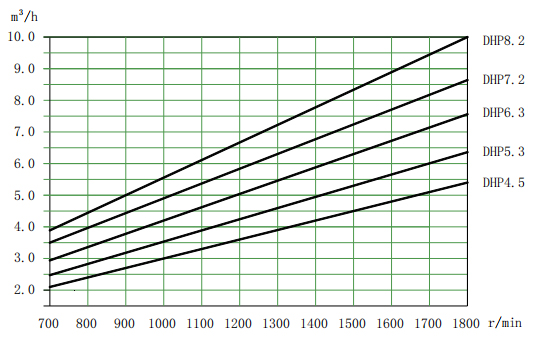

The DHP 8.2 belongs to the DHP4.5 to 8.2 series and is a fixed-displacement pump. At an operating pressure of 80 bar, its flow rate is strictly proportional to the speed. The flow rate graph provides a visual representation of flow rates at different speeds: the horizontal axis represents speed (700 to 1800 rpm), and the vertical axis represents flow rate (0 to 10.0 m³/h). For example:

At 1000 rpm, the flow rate is approximately 5.5 m³/h;

At 1300 rpm, the flow rate is approximately 7.1 m³/h;

At the rated speed of 1500 rpm, the flow rate stabilizes at 8.2 m³/h.

To calculate the target speed for a specific flow requirement, use the following formula:

Selected Motor Speed (r/min) = (Required Flow Rate (m³/h) × Rated Speed 1500 (r/min)) / Rated Flow Rate 8.2 (m³/h)

For instance, if an industrial desalination system requires a flow rate of 6.0 m³/h, the required speed is (6.0×1500)/8.2 ≈ 1109 rpm—ensuring accurate and straightforward calculation.

Port Identification: The pump body is marked with "I" for inlet and "O" for outlet. Both ports have dimensions of M42×1.5 (22 mm depth). Ensure pipeline connections match the thread specifications to avoid damage from forced fitting. Use high-pressure PTFE gaskets to ensure sealing, controlling leakage to ≤3 drops per minute.

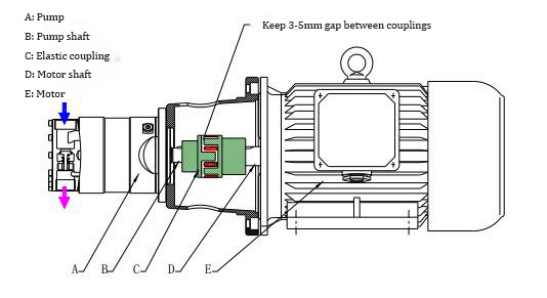

Motor coupling: A clearance of 3 to 5 mm should be maintained between the pump and motor coupling. Ensure the pump shaft is not subject to axial or radial loads (such as from the weight of the pipe or misalignment) to prevent premature wear of the shaft seal and bearings. Refer to the standard motor-high-pressure pump connection diagram for accurate installation:

Foundation & Piping: Install the pump unit on a concrete base with vibration dampers (rated load ≥50 kg, stiffness matching the pump’s vibration frequency) to reduce vibration transmission during medium-speed operation. Use inlet pipes no smaller than the pump’s port size, minimize pipeline length (≤5 m recommended), and limit bends (≤2 bends, with radius ≥5×pipe diameter) to reduce pressure loss. Maintain stable inlet pressure (2~5 Bar) to avoid cavitation from pressure fluctuations.

Filtration Configuration: Impurities (e.g., sediment, suspended solids) in seawater or industrial wastewater can wear precision plungers and sleeves. Install a 10 μm absolute filter (filtration efficiency ≥99.98%, β10>5000) before the pump inlet. Never use bag or spiral-wound filters with only 90% efficiency—these allow particle leakage, causing rapid component wear and reducing service life to under 4000 hours.

Pressure Protection: Install a low-pressure control switch (set to 2 Bar) at the inlet to shut down the pump automatically if inlet pressure drops below this value, preventing dry running (dry running for over 5 minutes may ruin plungers due to friction). Install a high-pressure control switch (set to 70 Bar) and a safety valve (5~9 MPa adjustable, customizable) between the pump outlet and reverse osmosis membrane to prevent membrane damage (reverse osmosis membranes typically withstand ≤75 Bar).

Start-Up/Shutdown & Flushing: In high-salinity scenarios (e.g., seawater desalination), flush the pump chamber with fresh water for ≥15 minutes after each shutdown to remove residual concentrated brine (long-term residue causes crystallization and blockages, leading to sudden pressure spikes over 100 Bar on restart). Flush with fresh water if shutdown exceeds 3 days; use fresh water with a bactericide (e.g., 50 ppm sodium hypochlorite) if shutdown exceeds 15 days. Never start the pump with the downstream valve closed—this may trigger the safety valve or cause pipeline bursts.

The power consumption of DHP 8.2 varies with the working pressure. The power requirements at the rated speed of 1500 rpm are specified as shown in the following table:

| Pump Model | Rated Flow (L/min) | Rated Flow (m³/h) | Power at 60 Bar | Power at 70 Bar | Power at 80 Bar | Rated Speed (rpm) |

|---|

| DHP 8.2 | 136 | 8.2 | 18.5 kW | 22.0 kW | 30.0 kW | 1500 |

Seawater desalination systems typically operate at 70~80 Bar, so a 30.0 kW motor (protection class ≥IP54, insulation class ≥Class F) is recommended for stable operation without energy waste. For industrial desalination at lower pressures (e.g., <60 Bar), an 18.5 kW motor suffices, reducing initial configuration and long-term energy costs.

| Piston Pump Model | Inlet Size | Outlet Size |

|---|

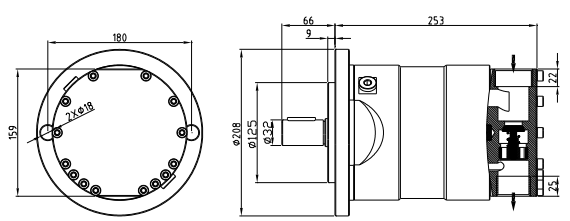

| DHP 8.2 | M42×1.5, 22 mm Depth | M42×1.5, 22 mm Depth |

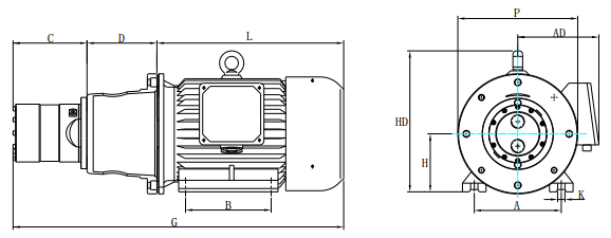

The following are examples of dimensions for DHP 8.2 motors used in common applications, which can be used as a reference for installation space planning (e.g., industrial desalination equipment rooms, medium-sized desalination plants – allow ≥600mm of maintenance space):

| Piston Pump | A | B | H | K | P | AD | HD | C | D | L | G | IEC Motor |

|---|

| DHP 8.2 | 279 | 279 | 180 | 15 | 350 | 265 | 445 | 253 | 204 | 735 | 1199 | 22 kW - 4P |

| DHP 8.2 | 318 | 305 | 200 | 19 | 350 | 305 | 505 | 253 | 204 | 765 | 1222 | 30 kW - 4P |

Lubrication Management: The transferred fluid serves as the lubricant—no additional lubricating oil is needed. Daily maintenance only requires checking filter pressure difference: replace the filter element within 24 hours if the pressure difference exceeds 0.5 Bar, ensuring inlet fluid cleanliness ≤10 NTU.

Regular Inspection: Under standard operating conditions (10 μm filtration, normal pressure/speed), perform a partial inspection (check shaft seal tightness and plunger mobility) every 6000 hours, and a full inspection every 8000 hours. Focus on plunger and sleeve wear—replace parts if the wear gap exceeds 0.12 mm. Timely replacement of worn components ensures pump flow and pressure stability (flow attenuation ≤5% per 8000 hours).

Corrosion Protection: While the pump body uses 2205 duplex stainless steel (excellent corrosion resistance), strictly follow shutdown flushing procedures in high-salinity scenarios (e.g., seawater desalination): flush with fresh water for 15~20 minutes after each shutdown to keep residual salt concentration in the pump chamber ≤500 ppm. This prevents salt crystallization on flow channel walls and subsequent local pitting (pitting depth ≤0.1 mm), which could compromise sealing and service life.

Basic Warranty: 1 year of free maintenance from the date of shipment (excludes damage caused by human error or non-compliant operation, e.g., component wear from missing filters or pump body cracking from overpressure).

Extended Coverage: If operated under specified conditions (meets filtration, pressure, and speed requirements), the pump qualifies for an 8000-hour maintenance-free warranty (maximum 18 months from shipment).

After-Sales Support: The manufacturer provides fault diagnosis (≤24-hour response), on-site maintenance (nationwide coverage), factory repair, and spare parts supply (≤7 working days delivery). For support, use the contact information below.

Company: WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. (FG Water Technologies)

Address: Chuangyi Industrial Park, No. 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, P. R. China

Tel: +86-510-85163211

Mobile: +86-13646187144

Email: [email protected]

Official Website: https://www.fgwater.com

WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. (FG Water Technologies), the manufacturer of DHP 8.2, has specialized in R&D of high-pressure piston pumps since 1990 and is China’s first producer of axial high-pressure piston pumps. After nearly 15 years of in-depth development and innovation, it has achieved localization of axial high-pressure piston pumps—with technical standards and product quality on par with global leaders. Its production scale ranks among the top in China’s industry, effectively resolving the historical bottleneck of relying on imported products in related fields (e.g., early seawater desalination projects relied entirely on imported high-pressure pumps, leading to high costs and slow after-sales support).

In collaboration with its OEM partner, Shenzhen CW Environment Technology, the company widely applies axial high-pressure piston pumps in seawater desalination, industrial desalination, and membrane concentration. Adhering to the principle of "Quality First, Integrity-Based, Customer Satisfaction", it continuously optimizes its supply chain and sales service system—with service outlets in over 30 cities across China and overseas coverage in seawater desalination-intensive regions such as Southeast Asia and the Middle East. The company is committed to providing customers with efficient core fluid equipment and technical solutions, supporting the implementation of China’s "Made in China 2025" strategy and industrial foundation enhancement initiatives.

PDF manual download address:DHP type plunger pump selection manual.pdf