LCM-3T Industrial EDI Module 2.8-3.2m³/h Ultra-pure Water Equipment as a Replacement for Veolia MK-3 An Efficient and Eco-friendly Choice

As an industrial-grade EDI module specifically designed to replace Veolia MK-3, the LCM-3T has a water production range of 2.8-3.2m³/h, perfectly matching the flow requirements of the original system, while achieving breakthroughs in performance and cost control:

Seamless Replacement without Modification: Its dimensions and installation interfaces are compatible with Veolia MK-3, enabling direct replacement and immediate use. A certain electronics factory completed the replacement in only 8 hours, saving 3 days of construction period compared to redeploying the system.

More Stable Water Production Quality: The product water resistivity is stably maintained at 15-18MΩ·CM, with a silica removal rate of up to 99% (effluent ≤5ppb) and a sodium removal rate of ≥99.9%. After a photovoltaic enterprise used it, the yield rate of silicon wafer cleaning increased by 3%.

Operating Costs Reduced by 40%: Compared with MK-3, the power consumption is reduced by 15%, and the concentrated water recovery rate is increased to 95%. A semiconductor factory calculated that it saves 18,000 tons of water and 23,000 yuan in electricity bills annually.

Optimized Polar Water Flow: Only 80L/h of polar water flow is required, which is 50% less than traditional models, significantly reducing the pressure of wastewater treatment and meeting strict environmental protection standards.

| Parameter Item | Specific Value |

|---|

| Flow Range | 2.8-3.2m³/h |

| Polar Water Flow | 80L/h |

| Operating Current | 2.5A (0-6A adjustable) |

| Operating Voltage | 0-340VDC |

| Maximum Power | 2KW/H |

| Shipping Weight | 112KG |

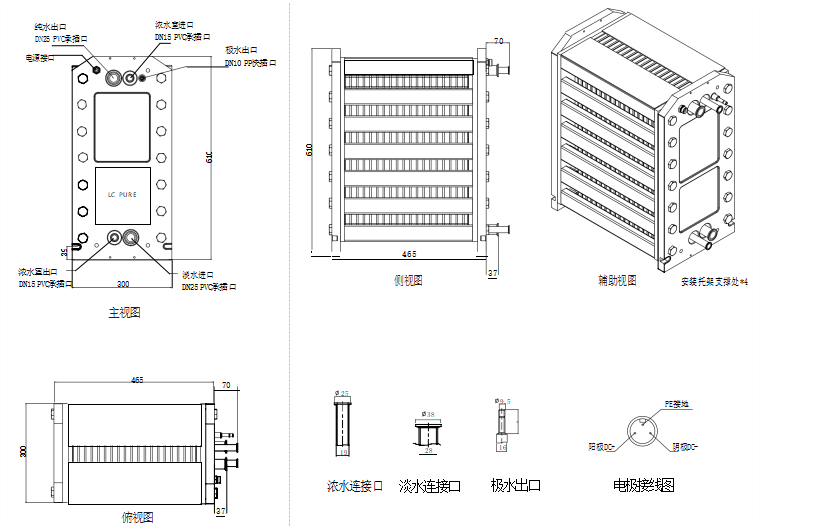

| Overall Dimensions (H×W×Total Length A) | 610×300×465mm |

| Fresh Water Interface | DN25 Inner Thread |

| Concentrated Water Interface | DN20 Inner Thread |

| Polar Water Outlet | DN10 PP Quick Connector |

| Standard Pressure Drop of Fresh Water Inlet/Outlet | 0.2-0.4MPa |

| Pressure Difference between Fresh Water Outlet and Concentrated Water Inlet | 0.1-0.25MPa |

| Water Inlet Requirement | RO product water (conductivity ≤5μS/cm) |

| Product Water Quality | ≥15MΩ·CM |

Case: System Upgrade in a 300mm Wafer Factory

The original 4 sets of Veolia MK-3 modules affected production due to high maintenance costs and long spare parts procurement cycles. After all being replaced with LCM-3T in 2024:

The downtime for maintenance was shortened from 12 hours to 4 hours each time, reducing annual production capacity loss by 1.5 million yuan;

The cost of consumables was reduced by 60%, and there was no need to rely on imported spare parts, with the response speed increased to within 24 hours;

The TOC of the produced water was stably ≤10ppb, meeting the strict requirements for ultra-pure water in advanced manufacturing processes.

Semiconductor manufacturing: High-purity water links such as wafer cleaning and photolithography development

Photovoltaic industry: Ultra-pure water preparation for silicon wafer cutting and battery piece cleaning

Fine chemicals: Process water for high-end chemical synthesis

Power industry: Advanced desalination treatment of boiler make-up water

Pharmaceutical field: Precision treatment stage of water for injection systems

LCM-3T not only matches or even surpasses Veolia MK-3 in performance but also solves the pain points of high maintenance costs and slow spare parts supply of imported equipment. Its standardized design supports single-module maintenance and is compatible with the original pipelines and control systems. It is a cost-effective choice for MK-3 users to upgrade and transform, which can not only ensure the quality of produced water but also significantly reduce the whole-life cycle cost.

Get Replacement Solutions

Official website: https://www.fgwater.com

Consultation hotline: +86-13646187144

Email: [email protected]

LCM series EDI membrane stack appearance dimension diagram (3T)