LCM-5T Industrial EDI Module 4.8-5.3m³/h Ultra-pure Water Equipment as a Replacement for Veolia MK-5 A High-flow Upgrade Choice

As a replacement industrial EDI module designed for Veolia MK-5, the LCM-5T features a water production range of 4.8-5.3m³/h, perfectly matching the flow requirements of the original system. While maintaining compatibility, it achieves a comprehensive performance upgrade:

Plug-and-play Compatibility: The size and interface design are fully adapted to MK-5 installation standards. A petrochemical enterprise completed the replacement of 3 units in only 10 hours, shortening the system commissioning time by 60% and avoiding losses from long-term shutdowns.

Comprehensive Improvement in Water Quality: The product water resistivity stably reaches 16-18MΩ·CM, with boron removal rate increased to 96% (effluent ≤0.08ppb) and silica removal rate up to 99%. After a semiconductor factory adopted it, the defect rate in the chip etching process decreased by 2.3%.

Significant Optimization of Operating Costs: Compared with MK-5, power consumption is reduced by 12%, and concentrated water recovery rate is increased to 95%. A coal chemical base calculated that it saves 30,000 tons of water annually, reduces electricity costs by 45,000 yuan, and cuts polar water discharge by 50%.

More Efficient Modular Maintenance: Supports online maintenance of single membrane stacks. Through intelligent flow distribution technology, the system's water production only decreases by 15% during maintenance. During the maintenance of an industrial park, the shutdown loss was reduced by 800,000 yuan per incident.

| Parameter Item | Specific Value |

|---|

| Flow Range | 4.8-5.3m³/h |

| Polar Water Flow | 80L/h |

| Operating Current | 2.5A (0-6A adjustable) |

| Operating Voltage | 0-550VDC |

| Maximum Power | 3KW/H |

| Shipping Weight | 143KG |

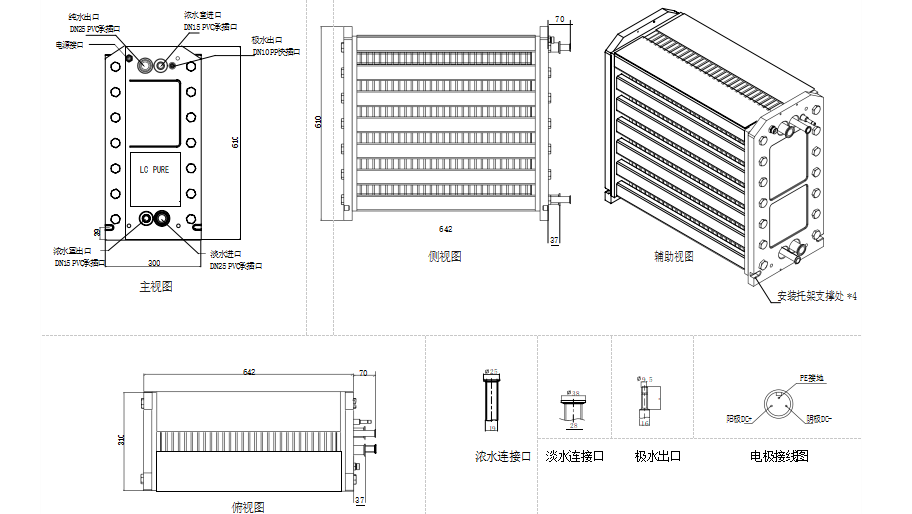

| Overall Dimensions (H×W×Total Length A) | 610×300×642mm |

| Fresh Water Interface | DN25 Inner Thread |

| Concentrated Water Interface | DN20 Inner Thread |

| Polar Water Outlet | DN10 PP Quick Connector |

| Standard Pressure Drop of Fresh Water Inlet/Outlet | 0.2-0.4MPa |

| Pressure Difference between Fresh Water Outlet and Concentrated Water Inlet | 0.1-0.25MPa |

| Water Inlet Requirement | RO product water (conductivity ≤5μS/cm) |

| Product Water Quality | ≥15MΩ·CM |

Case: System Transformation in a Green Hydrogen Production Base

The original 2 sets of Veolia MK-5 modules affected electrolyzer efficiency due to water production fluctuations. After being replaced with LCM-5T in 2024:

The product water resistivity stabilized at 17.5±0.3MΩ·CM, and hydrogen purity increased to 99.999%, meeting green hydrogen export standards;

The equipment maintenance cycle was extended from 3 months to 6 months, annual maintenance costs were reduced by 55%, and the spare parts procurement cycle was shortened from 45 days to 7 days;

The overall energy consumption of the system decreased by 8%, helping the base qualify for green energy subsidies.

Green hydrogen industry: Ultra-pure water preparation for electrolyzer water supply systems

Semiconductor manufacturing: High-purity water for 12-inch wafer production lines

Large thermal power: Advanced treatment of high-pressure boiler make-up water

Fine chemicals: Process water for high-end catalyst production

Photovoltaic industry: Ultra-pure water supply for large-size silicon wafer cleaning

LCM-5T not only solves the pain points of high maintenance costs and reliance on imported spare parts of MK-5 but also achieves 24-hour response with localized services. Its standardized design is compatible with original pipelines and control systems. A single system can support parallel operation of up to 8 units, easily meeting ultra-large flow demands of over 40m³/h. It is a high-performance and low-cost choice for MK-5 users to upgrade and transform.

Get Custom Replacement Solutions

Official website: https://www.fgwater.com

Consultation hotline: +86-13646187144

Email: [email protected]

LCM series EDI membrane stack appearance dimension diagram (5T)

Link address for each model