LC PURE Industrial General-Purpose LC-500 EDI Module Providing Efficient and Stable Solutions for Medium-Scale Pure Water Needs

In the field of water treatment technology, EDI (Electrodeionization) technology has become an important means of producing high-purity water due to its advantages such as continuous water production and no need for acid-base regeneration. The LC PURE Industrial General-Purpose LC-500 EDI module is an outstanding one among many products, designed specifically for medium-scale pure water demand scenarios, and has won wide recognition for its excellent performance and stable performance.

The reason why the LC-500 EDI module can stand out among many products is that it integrates many core advantages of EDI technology:

Continuous and stable water production: It can continuously produce high-purity water without the need for complex regeneration operations like traditional mixed beds, eliminating the trouble of frequent shutdowns for maintenance, ensuring the continuity of production, and reducing the investment in standby equipment.

Environmental protection and energy saving: No acid or alkali is used in the entire operation process, avoiding the problems of neutralization, discharge and treatment of waste acid and alkali. It is a green and environmental protection technology, which meets the strict environmental protection requirements of modern industry. At the same time, concentrated water can be directly reused, the amount of electrode water discharged is small, and the operating cost is low.

Convenient installation and small footprint: The installation conditions are simple and the floor area is small, which can adapt to the installation needs of different sites, especially suitable for industrial sites with limited space.

Stable water quality: The quality of the produced water is stable and reliable, without the water quality fluctuation like ordinary mixed beds, which can continuously meet the strict requirements of production for water quality. The quality of the produced water can reach 5-18 MΩ·cm.

| Parameter Category | Specific Value |

|---|

| Standard water production flow | 0.5m³/h |

| Maximum water production flow | 0.8m³/h |

| Minimum water production flow | 0.4m³/h |

| Operating voltage | 0-200VDC |

| Operating current | 2.5A (0-6A range) |

| Number of membrane pairs | 6 |

| Operating net weight | 48KG |

| Maximum power | 1.2KW/H |

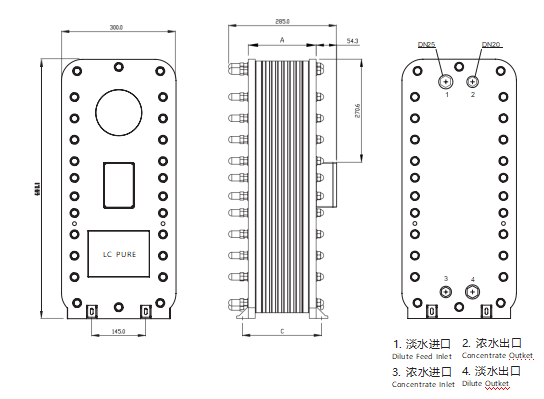

| Fresh water inlet/outlet | DN25 PVC |

| Concentrated water inlet/outlet | DN20 PVC |

| Total length B (mm) | 275 |

| Center length A (mm) | 167 |

| Front and rear positioning length C (mm) | 200 |

| Overall height (mm) | 680 |

| Overall width (mm) | 300 |

| Left and right positioning (mm) | 14.5 |

A medium-sized electronic component manufacturer needs to use high-purity water for cleaning electronic components during its production process, which has extremely high requirements for water quality, and the conductivity needs to be stable at a low level. Previously, traditional mixed bed equipment was used, which not only required regular acid-base regeneration, with cumbersome maintenance, but also often caused water quality fluctuations due to the regeneration process, affecting product quality, and the cost of waste acid and alkali treatment was high.

After introducing the LC PURE Industrial General-Purpose LC-500 EDI module, the situation has been significantly improved. The module continuously and stably produces high-purity water, meeting the strict water quality requirements for cleaning electronic components. The quality of the produced water is stable, and there are no longer product quality problems caused by water quality fluctuations. At the same time, there is no need for acid-base regeneration operations, saving a lot of maintenance time and costs, and avoiding the environmental pressure caused by waste acid and alkali treatment. Its small footprint also well adapts to the limited space layout of the factory's workshop. After being put into use, the production efficiency of the factory has been improved, the comprehensive operating cost has been reduced, and good economic and environmental benefits have been achieved.

With its efficient, stable and environmentally friendly characteristics, the LC PURE Industrial General-Purpose LC-500 EDI module provides an ideal solution for medium-scale pure water demand scenarios and shows broad application prospects in many industries such as electronics, medicine and chemical industry.