LC PURE Industrial General-Purpose LC-2000 An Efficient and Stable Tool for Industrial Ultrapure Water Preparation

In industrial production, the stable supply of ultrapure water is crucial for many industries to maintain normal operations and ensure product quality. The LC PURE Industrial General-Purpose LC-2000 EDI membrane stack, with its excellent performance, has become an ideal choice in the field of industrial ultrapure water preparation.

The LC-2000 EDI membrane stack adopts innovative EDI technology, which organically combines electrodialysis and ion exchange, belonging to high-tech green environmental protection technology. It uses mixed ion exchange resins to adsorb cations and anions in water, and at the same time, under the action of a DC electric field, these ions are removed through anion and cation exchange membranes respectively, thereby continuously and stably producing ultrapure water.

This membrane stack does not require acid-base regeneration, eliminating the complex regeneration operations in the process of using mixed beds, reducing a large number of standby equipment, and lowering labor and material costs. Its installation conditions are simple and it covers a small area, so it can be easily integrated into various industrial site layouts. Moreover, there is no need to treat waste acid and alkali during operation, and there is no neutralization, discharge and treatment system for waste acid and alkali. The concentrated water can be directly reused, and the amount of polar water discharged is small, which conforms to the development concept of green environmental protection and reduces the operation cost. In addition, the effluent quality of LC-2000 is stable, without the water quality fluctuation like ordinary mixed beds, and can provide a continuous and reliable high-purity water source for industrial production.

| Model Category | LC-2000 |

|---|

| Standard Product Water Flow (m³/h) | 2 |

| Maximum Product Water Flow (m³/h) | 2.3 |

| Minimum Product Water Flow (m³/h) | 1.8 |

| Operating Voltage (VDC) | 0-340 |

| Operating Current (0-6A) | 2.5 |

| Number of Membrane Pairs | 22 |

| Operating Net Weight (KG) | 95 |

| Maximum Power (KW/H) | 2 |

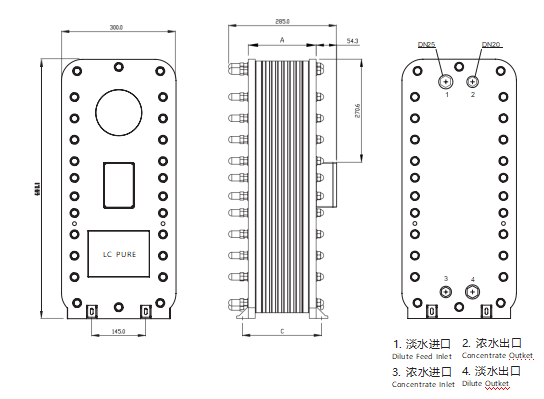

| Fresh Water Inlet/Outlet | DN25 PVC |

| Concentrated Water Inlet/Outlet | DN20 PVC |

| Total Length B (mm) | 525 |

| Center Length A (mm) | 415 |

| Front and Rear Positioning Length C (mm) | 455 |

| Overall Height (mm) | 680 |

| Overall Width (mm) | 300 |

| Left and Right Positioning (mm) | 14.5 |

A large electronic component manufacturer has extremely high requirements for the quality of ultrapure water used in the production process, and the conductivity needs to be stably above 15MΩ·cm. Previously, the traditional mixed bed process was adopted, which not only required frequent regeneration, consumed a large amount of acid and alkali, but also often affected product quality due to water quality fluctuations.

After introducing the LC PURE Industrial General-Purpose LC-2000 EDI membrane stack, the situation has been completely improved. The membrane stack continuously and stably produces ultrapure water that meets the requirements, with minimal water quality fluctuation, ensuring the stability and qualification rate of electronic component production. At the same time, it eliminates the acid-base regeneration link, reduces environmental pollution, and also reduces the production interruption time caused by regeneration, improving the overall production efficiency. After more than a year of operation, the equipment has a low failure rate and low maintenance cost, bringing significant economic and environmental benefits to the enterprise.

The LC PURE Industrial General-Purpose LC-2000 EDI membrane stack, with its efficient, stable and environmentally friendly characteristics, has shown great application value in many industrial fields such as electronics, semiconductors, electric power and chemical industry, providing a reliable guarantee for industrial ultrapure water preparation.