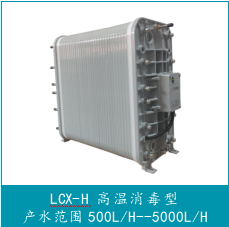

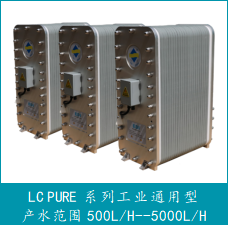

LC Series EDI Modules Industrial High-Temp (LCX-H) - Efficient Ultrapure Water Solutions for Diverse Industrial Needs

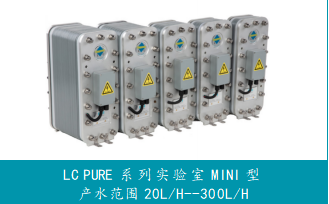

In the field of industrial ultrapure water preparation, the LC Series EDI membrane stacks occupy an important position with their excellent performance and innovative technology. As an environmentally friendly equipment integrating the advantages of electrodialysis and ion exchange, this series covers industrial general-purpose types (LCX, LCM, and LC Classic Series), laboratory MINI Series, and high-temperature disinfection type (LCX-H Series), which can meet the diverse water production needs ranging from 0.02 m³/h to 7.3 m³/h. Among them, the LCX-H Series is particularly notable for its ability to withstand inlet water temperatures of 60°C and support high-temperature disinfection at 85°C, providing a reliable solution for continuous water production (with water quality reaching above 10 MΩ·CM) under high-temperature working conditions. It completely eliminates the acid-base regeneration process of traditional mixed beds and, with the advantages of fully automatic operation, low energy consumption, and stable water output, is widely suitable for ultrapure water preparation scenarios in stringent industries such as pharmaceuticals, electronics, and photovoltaics.

TEH WORKING PRINCIPLE OF EDI MODULE

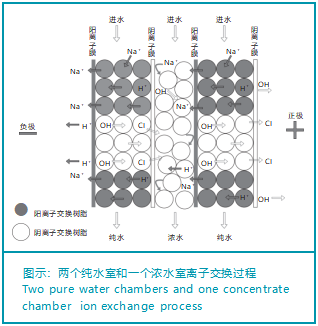

The working principle of EDI membrane stack is as follows:

EDI uses mixed ion exchange resin to adsorb cations and anions in water, and these adsorbed ions are removed through ion exchange membranes under the action of DC voltage.

A freshwater chamber is formed between the anion exchange membrane facing the positive electrode and the cation exchange membrane facing the negative electrode; a concentrated water chamber is formed between the anion membrane facing the negative electrode and the cation membrane facing the positive electrode.

Anion and cation resins are sandwiched between the freshwater and concentrated water chambers. When water flows through these chambers, the ion exchange resin adsorbs ions in the water.

The electrodes at both ends of the EDI membrane stack provide a transverse DC electric field, which drives the ions adsorbed by the ion exchange resin to pass through the ion exchange membrane.

This process reduces ion concentration in the freshwater chamber and increases it in the concentrated water chamber, thereby enhancing the purity of water in the freshwater chamber.

An EDI membrane stack consists of multiple such basic units working in parallel.

ADVANTAGES OF EDI MODULE PROCESS

Simple installation conditions with a small footprint during setup.

No need to treat acidic or alkaline waste, eliminating the need for neutralization and treatment systems; electrodialysis concentrate water can be directly reused, with minimal electrode water discharge.

Low operating costs, offering competitive pricing compared to various mixed beds.

Practical design enables easy maintenance and capacity expansion, requiring only brief downtime for replacement.

Stable EDI output water quality, free from fluctuations typical of ordinary mixed beds.

Easy installation and maintenance: single-module maintenance is possible by redistributing flow to other membrane stacks without compromising system performance.

Standardized design using modular units to meet diverse water consumption needs.

EDI INLET WATER QUALITY REQUIREMENTS

EDI (Electrodeionization) is an innovative water treatment technology that combines electrodialysis with ion exchange in a membrane separation desalination process. It is a high-tech, environmentally friendly technology.

EDI water purification equipment offers advantages such as continuous water output, no need for acid and alkali regeneration, and unattended operation.

LC PURE EDI uses direct current to drive positively and negatively charged ions in water to move directionally under a DC electric field, passing through anion and cation exchange membranes on both sides of the freshwater chamber. Cations are attracted by the negative electrode and pass through the cation membrane to be discharged from the concentrated water chamber, while anions are attracted by the positive electrode and pass through the anion membrane for discharge—enabling continuous production of ultra-pure water.

This technology stably produces high-purity water with a resistivity of 5-18 megohms (MΩ·cm).

EDI technology has gradually replaced mixed beds as precision treatment equipment in pure water systems, boasting excellent environmental protection properties and easy operation. It is widely used in industries such as medicine, electronics, semiconductors, photovoltaics, power, chemicals, and vehicle urea purification.

Its emergence marks a revolutionary advancement in water treatment, achieving ultra-pure water processes without acid and alkali emissions.

EDI Inlet Water Quality Requirements

| Item | Requirements |

|---|

| Inlet Water Source | Must be reverse osmosis (RO) product water |

| Inlet Conductance | <10μs/cm (including CO₂ and silicon); <5μs/cm is better for extending service life and reducing loss |

| Temperature | 5-30℃ |

| Inlet Water Pressure | 0.1-0.3MPa |

| Maximum Total Cl₂ Content | <0.02 ppm |

| Iron (Fe) | <0.01 ppm |

| Manganese (Mn) | <0.01 ppm |

| Sulphide (S⁻) | <0.01 ppm |

| pH Value | 7-8 |

| Total Hardness (as CaCO₃) | <0.5 ppm |

| Total Organic Carbon (TOC, as C) | <0.5 ppm |

| Silicon (as SiO₂) | <0.5 ppm |

| Oxidizing Material | Not detected |

| Oil/Fat | Not detected |

EDI Operating Parameters

| 项目(Item) | 数值范围(Value Range) |

|---|

| 回收率(Rate of Recovery) | 85-95% |

| 最大进水压力(Maximum Inlet Pressure) | 0.5MPa |

| 正常流量时的压降范围(Pressure Drop Range at Normal Flow) | 0.1-0.3MPa |

| 最高进水温度(Maximum Inlet Water Temperature) | 25℃ |

| 进水电导(Inlet Water Conductivity) | ≦ 5μS/cm |

| 产水水质(Product Water Resistivity) | ≧ 15MΩ·CM |

LC Series EDI Membrane Stack LC PURE EDI-PRODUCT TYPE

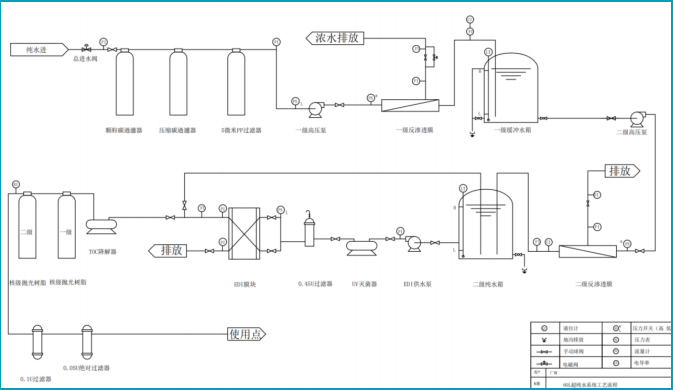

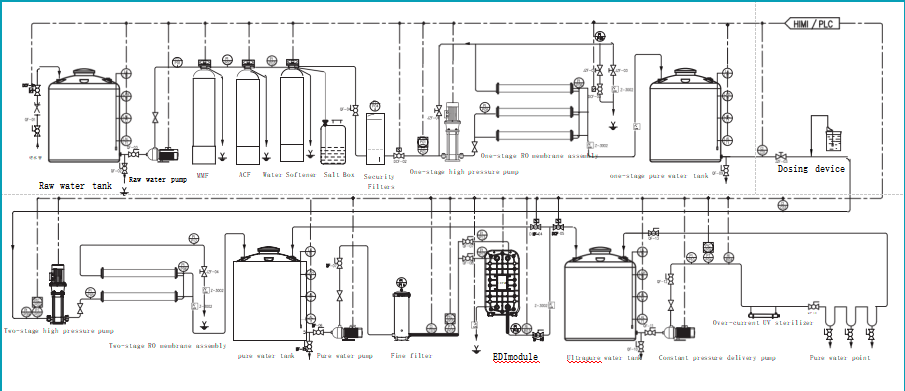

EDI PURE WATER SYSTEM FLOW SHEET

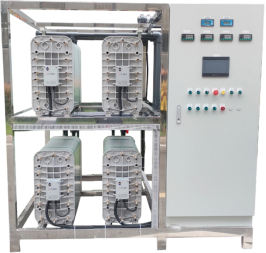

DEIONIZED WATER EQUIPMENT

Pressure Gauge

Measures the pressure range during EDI operation. The specific range refers to standard parameters.

Flowmeter

Measures the flow rate of both fresh water and concentrated water.

Conductance and Resistance Meter

Measures the conductance of incoming water and the resistance of EDI produced water.

Serves as part of the water quality monitoring in the control system, providing signals for excessive inflow and output to trigger alarms and protection.

Control Center

Offers both manual and automatic operation modes.

Automatic mode: If water flow or pressure is too low, it first cuts off the DC power in the RO system to stop water production and electricity supply. When conductance is too high, EDI shuts down with sound and light alarms. If EDI feed water pressure is too high, the pressure relief valve activates and alarms.

Manual mode: Not subject to any automatic control.

DC Power Supply

An adjustable high-frequency DC power supply equipped with current and voltmeters.

To ensure system stability, it is recommended to adopt one-to-one control for the power supply.

Flow Pressure Switch

Detects the flow or pressure entering the EDI.

Triggers an alarm and shuts off the corresponding membrane power when the flow or pressure is below the set value.

EDI Membrane Block

Select the appropriate type of membrane block according to actual water demand, or use multiple membrane blocks in parallel to achieve greater water yield.

EDI concentrated water can be reused as RO inlet water (flowing back to the source water tank), discharged into sewers, or used for other purposes.

Control Valve

Adjusts the water pressure and flow of each unit to keep the membrane block in optimal condition.

The pressure of the fresh water inlet and outlet should be 0.15 MPa higher than that of the concentrated water inlet and outlet.

The water inlet electric (magnetic) valve automatically switches on/off with the system's start-up and shu

LABORATORY PURE WATER EQUIPMENT