LCX-20T EDI Module 1.8-2.3m³/h Ultra-pure Water Equipment Preferred for PV/Electronics Industries

As a key model in the LCX series of industrial general-purpose EDI membrane stacks, the LCX-20T is designed for flow rate requirements of 1.8-2.3m³/h. Leveraging advanced Electrodeionization (EDI) technology, it provides an excellent solution for ultra-pure water preparation in medium-sized industries.

There is no need for acid-base regeneration, bid farewell to the cumbersome operations and pollution problems of traditional mixed beds. After a photovoltaic enterprise used it, the annual cost of acid and alkali procurement was reduced by about 80,000 yuan, and the wastewater treatment cost was reduced by 60%. The product water resistivity is stably maintained at ≥15MΩ·CM, meeting the scenarios with extremely high water quality requirements such as electronic chip cleaning. After an electronics factory replaced it, the product defect rate caused by water quality fluctuations dropped from 3% to 0.5%.

The operating power is only 2KW/H, and the concentrated water recovery rate reaches 85-95%, which greatly reduces energy consumption and water waste. A chemical enterprise calculated that compared with the original system, it saves about 12,000 tons of water annually and nearly 15,000 yuan in electricity bills. The modular design supports single-module maintenance, and the overall operation is not affected by redistributing the flow. When a vehicle urea factory was undergoing maintenance, the downtime was shortened from 8 hours to 1.5 hours.

| Parameter Item | Specific Value |

|---|

| Flow Range | 1.8-2.3m³/h |

| Operating Current | 2.5A (0-6A adjustable) |

| Operating Voltage | 0-340VDC |

| Maximum Power | 2KW/H |

| Transportation Weight | 75KG |

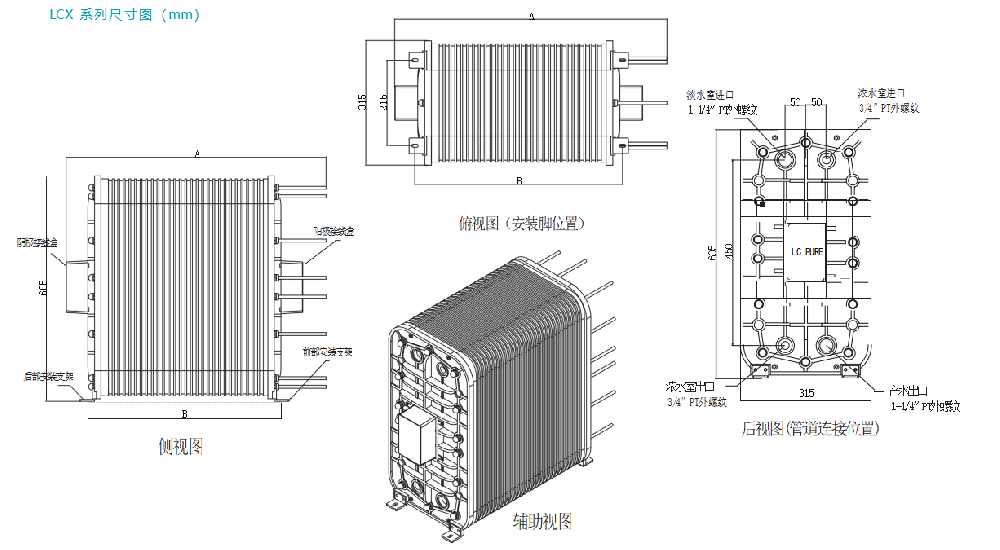

| Overall Dimensions (H×W×Total Length A) | 605×315×560mm |

| Left-Right Positioning Center Distance | 215mm |

| Front-Back Positioning Center Distance B | 385mm |

| Fresh Water Interface | 1-1/4″PT Male Thread |

| Concentrated Water Interface | 3/4″PT Male Thread |

| Water Inlet Requirement | RO product water (conductivity ≤5μS/cm) |

| Product Water Quality | ≥15MΩ·CM |

Case 1: Water Production Upgrade in a 300MW PV Module Factory

A 300MW PV module factory's original mixed bed system needed regeneration every 3 days, consuming 30L of hydrochloric acid and 25L of sodium hydroxide each time. The 4-hour shutdown affected production capacity, and the wastewater treatment cost was high. After replacing with LCX-20T in 2023:

The regeneration operation was cancelled, reducing annual downtime by about 480 hours and increasing production capacity by 12%.

The product water resistivity is stably maintained at 16-18MΩ·CM, meeting the high-purity requirements for PV cell cleaning.

The concentrated water is directly reused for workshop floor cleaning, saving about 8,000 tons of water annually.

Case 2: Efficiency Improvement in a Medium-sized Electronic Component Cleaning Workshop

A workshop producing precision connectors had about 500 products scrapped due to corrosion every month because of the original mixed bed water quality fluctuations (8-15MΩ·CM). After replacing with LCX-20T:

The product water resistivity is stably maintained at 17±0.5MΩ·CM, and the scrap rate is reduced to less than 30 pieces per month.

The equipment covers an area of only 0.8㎡, saving 60% of space compared with the original system, adapting to the compact layout of the workshop.

The fully automatic operation requires no special personnel on duty, reducing labor costs by 3,000 yuan per month.

The LCX-20T realizes ultra-pure water preparation through three steps: "ion adsorption - electric field drive - membrane separation":

Ion adsorption: The mixed ion exchange resin between the fresh water chamber and the concentrated water chamber adsorbs cations and anions such as Na⁺ and Cl⁻ in the incoming water.

Electric field drive: The DC electric field (0-340VDC) at both ends of the membrane stack promotes the directional migration of adsorbed ions, with cations passing through the cation membrane and anions passing through the anion membrane.

Purity separation: The ion concentration in the fresh water chamber continues to decrease, producing ultra-pure water; the ion concentration in the concentrated water chamber increases and can be reused, realizing efficient and continuous water production.

Photovoltaic industry: Water for cell cleaning and silicon wafer cutting cooling.

Electronic manufacturing: PCB board cleaning, pre-treatment for chip packaging.

Chemical production: Water supply for medium-sized reaction kettles, purification of fine chemicals.

Vehicle urea: Ultra-pure water preparation in mass production.

Precision machinery: Hydraulic system coolant, ultrasonic cleaning of components.

Choose LCX-20T to bring a stable, efficient and low-cost ultra-pure water solution to your medium-sized industrial water treatment system, improve production efficiency and reduce operational risks.

For exclusive solutions or case details:

Official website: https://www.fgwater.com

Email: [email protected]

Phone: +86-13646187144