LCX-30T EDI Module 2.5-3.2m³/h Ultra-pure Water Equipment an Excellent Choice for Industrial Water

Core Advantages, Meeting the Needs of Large-scale Industrial Water Usage

As a high-performance model in the LCX series of industrial EDI modules, the LCX-30T is specially designed for large-scale industrial applications, stably providing an ultra-pure water output of 2.5-3.2m³/h. Its advanced features make it an ideal choice for industries requiring high water volume and high purity.

Continuous Water Production, No Regeneration Needed, More Environmentally Friendly

Adopting advanced Electrodeionization (EDI) technology, the LCX-30T can continuously produce ultra-pure water with a resistivity of ≥15MΩ·CM, eliminating the need for traditional acid-base regeneration processes, which simplifies operations and is beneficial to environmental protection. For example, after a large semiconductor manufacturing plant switched to the LCX-30T, it reduced its annual acid and alkali procurement costs by approximately $150,000, and its wastewater treatment costs decreased by 70%, significantly reducing environmental and operational burdens.

Stable Water Quality, Almost No Fluctuations

The LCX-30T ensures stable water quality, with resistivity maintained at ≥15MΩ·CM. This stability is crucial in fields such as pharmaceutical production, where even slight fluctuations in water quality can have a significant impact on product quality. After a well-known pharmaceutical factory replaced with the LCX-30T, the product defect rate caused by water quality fluctuations dropped sharply from 5% to 0.3%, significantly improving product quality and production efficiency.

High Efficiency and Energy Saving, Low Operating Costs

The LCX-30T has reasonable energy consumption and a high concentrated water recovery rate of 85-95%, making it highly energy-efficient. A large chemical enterprise conducted a detailed cost analysis after using the LCX-30T and found that compared with the previous water treatment system, it saved about 20,000 tons of water annually and reduced electricity costs by nearly $30,000, with significant long-term savings.

Modular Design, Convenient Maintenance

The modular design of the LCX-30T allows for single-module maintenance. During maintenance, the flow can be redistributed to other modules to ensure the continuous operation of the entire system with minimal downtime. A large power plant has personally experienced this advantage, with maintenance downtime reduced from 10 hours with the old equipment to only 2 hours, greatly improving production continuity and efficiency.

LCX-30T Technical Parameter Table

Parameter | Details |

Flow Range | 2.5-3.2m³/h |

Operating Current | 2.5A (0-6A adjustable) |

Operating Voltage | 0-340VDC |

Maximum Power | 2KW/H |

Shipping Weight | 75KG |

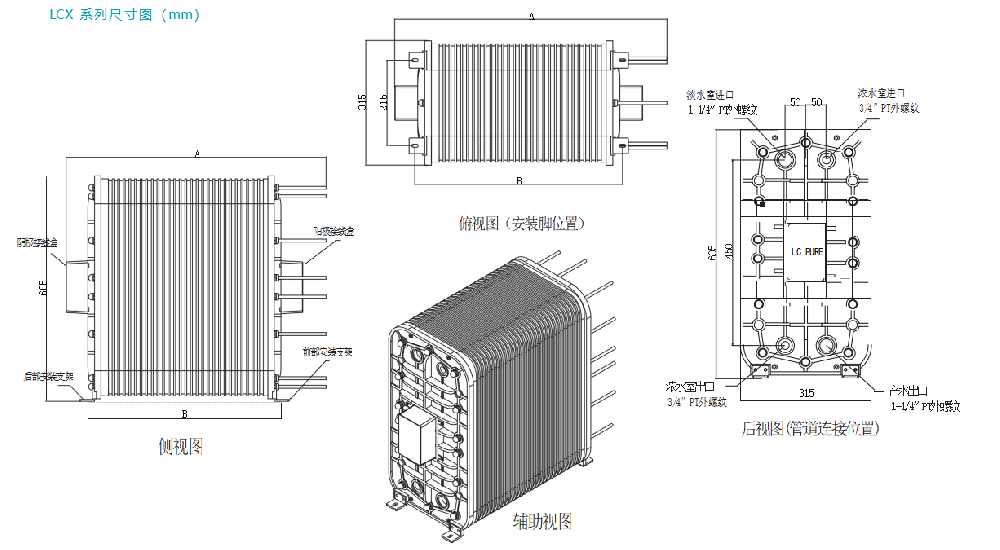

Overall Dimensions (Height × Width × Total Length A) | 605×315×560mm |

Left-Right Positioning Center Distance | 215mm |

Front-Back Positioning Center Distance B | 385mm |

Fresh Water Inlet/Outlet Connectors | 1-1/4″PT Male Thread |

Concentrated Water Inlet/Outlet Connectors | 3/4″PT Male Thread |

Water Inlet Requirement | RO product water (conductivity ≤5μS/cm) |

Product Water Quality | ≥15MΩ·CM |

Practical Cases, Demonstrating Excellent Performance

Case 1: Water Production Upgrade of a 500MW Photovoltaic Power Station

A 500MW photovoltaic power station used to employ a traditional water treatment system that required frequent regeneration. Each regeneration consumed a large amount of chemicals and caused significant production interruptions, affecting overall productivity. In 2024, the power station decided to upgrade to the LCX-30T, with remarkable results:

The regeneration process was completely eliminated, reducing annual downtime by approximately 600 hours and increasing productivity by 15%.

The water resistivity was stably maintained at 16-18MΩ·CM, fully meeting the high-purity requirements for photovoltaic cell cleaning.

The concentrated water could be directly reused in non-critical processes of the power station, saving about 10,000 tons of water annually.

Case 2: Efficiency Improvement of a Large Electronic Component Manufacturing Factory

A large factory producing high-end electronic components used to be troubled by water quality fluctuations. Its previous water treatment system was complex and aging, providing water with resistivity fluctuating between 8-15MΩ·CM, resulting in a large number of product scrappings due to corrosion every month. After adopting the LCX-30T:

The water resistivity was stabilized at 17±0.5MΩ·CM, and the product scrap rate dropped to less than 20 pieces per month.

The modular design of the LCX-30T made it easy to integrate into the existing production line, and its floor space was 50% less than that of the previous system.

The system's automatic operation and remote monitoring functions reduced the need for on-site personnel, lowering labor costs by $5,000 per month.

Working Principle of LCX-30T EDI

The LCX-30T achieves ultra-pure water production through three steps: "ion adsorption - electric field drive - membrane separation":

Ion Adsorption

The mixed ion exchange resin between the fresh water chamber and the concentrated water chamber adsorbs various cations and anions such as Na⁺ and Cl⁻ in the incoming water. This step helps capture impurities that need to be removed from the water.

Electric Field Drive

A DC electric field (0-340VDC) is applied across the module. This electric field exerts a force on the adsorbed ions, causing them to migrate in a specific direction, with cations passing through the cation exchange membrane and anions passing through the anion exchange membrane.

Purity Separation

As ions continue to migrate under the influence of the electric field, the ion concentration in the fresh water chamber steadily decreases, producing ultra-pure water; at the same time, the ion concentration in the concentrated water chamber increases, which can be further processed or reused in specific applications, ensuring efficient use of resources. This continuous process enables the LCX-30T to continuously and stably produce high-purity water.

Ideal Application Scenarios

Given its flow rate of 2.5-3.2m³/h and stable performance, the LCX-30T is widely used in the following industries:

Pharmaceutical Industry

In the pharmaceutical production process, the ultra-pure water produced by the LCX-30T ensures that no impurities are introduced into drugs, which is crucial for maintaining the quality and safety of pharmaceutical products.

In the preparation of pharmaceutical raw materials, stable water quality helps in accurate chemical reactions and reduces the risk of product contamination.

Semiconductor Industry

During semiconductor wafer cleaning, high-purity water can effectively remove contaminants without damaging the delicate semiconductor structures.

For semiconductor device manufacturing, the stable water quality of the LCX-30T is essential for ensuring the performance and reliability of the devices.

Large-Scale Chemical Production

It can provide high-purity water for large-scale reaction kettles, ensuring the accuracy and success of large-scale chemical reactions.

In the production of high-end chemicals, the LCX-30T's ability to produce ultra-pure water helps obtain high-quality chemical products with fewer impurities.

Power Generation (e.g., Nuclear Power Plants)

High-Tech Manufacturing

Why Choose LCX-30T?

For large-scale industrial users, the LCX-30T achieves a perfect balance. It not only meets the specific flow rate requirements of 2.5-3.2m³/h but also achieves low maintenance, high stability, and cost-effectiveness through advanced EDI technology. Whether you want to replace the existing traditional water treatment system or build a new water treatment line from scratch, the LCX-30T is an ideal choice. Its reliable performance can effectively reduce operational risks and significantly improve production efficiency.

For more detailed information, customized solutions, or to explore potential cooperation opportunities: