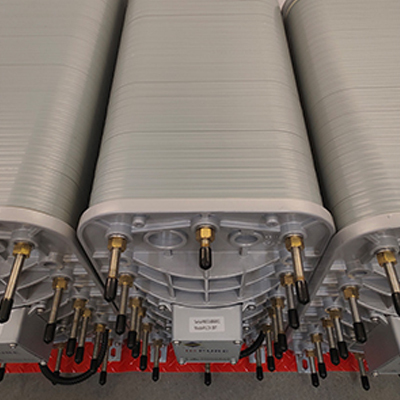

LCX-38T EDI Module 3.5-4.2m³/h Ultra-pure Water Equipment Ideal for Large-scale Industrial Efficient Water Treatment

Product Introduction

LCX-38T is a large-flow model in the LCX series of industrial-grade EDI modules, specially designed for large-scale industrial scenarios with a water production range of 3.5-4.2m³/h. Adopting advanced Electrodeionization (EDI) technology, it can stably produce ultra-pure water with a resistivity of ≥15MΩ·CM without acid-base regeneration. It is widely applicable to industries with strict water quality requirements such as semiconductors, photovoltaics, and pharmaceuticals, and is an efficient and environmentally friendly solution to replace traditional mixed bed systems.

Core Advantages

High Flow and Stable Water Production

The large-flow design of 3.5-4.2m³/h meets the continuous water demand of large production lines. A semiconductor industrial park adopts 3 LCX-38T modules in parallel operation, with a daily water production of over 300 tons, fully adapting to the peak water load of the 8-inch wafer cleaning line.

Regeneration-free and Low-cost Operation

It eliminates the links of acid-base procurement, storage, and regeneration, reducing annual operation and maintenance costs by more than 60%. After a large photovoltaic enterprise used it, it reduced hydrochloric acid consumption by 20 tons per year, saved 120,000 yuan in wastewater treatment costs, and reduced labor costs by 30%.

Extremely Stable Water Quality with Minimal Fluctuation

The water production resistivity is long-term stable at 15-18MΩ·CM, with a fluctuation of ≤±0.5MΩ·CM. After a pharmaceutical factory replaced the traditional system, the batch rejection rate caused by water quality fluctuation dropped from 2.3% to 0.15%.

Modular and Easy Maintenance Design

It supports online maintenance of single modules, and through automatic flow distribution technology, the system does not shut down during maintenance. During the maintenance of a chemical industrial park, the maintenance of a single equipment only takes 2 hours, which is 80% shorter than that of traditional equipment.

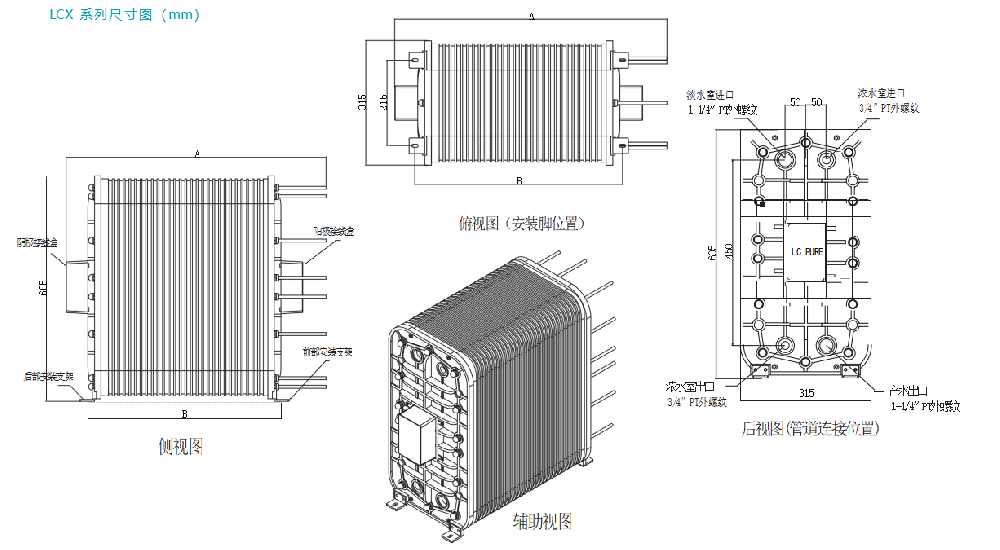

Technical Parameter Table

Parameter Item | Specific Value |

Flow Range | 3.5-4.2m³/h |

Operating Current | 3A (0-8A adjustable) |

Operating Voltage | 0-400VDC |

Maximum Power | 3.2KW/H |

Shipping Weight | 120KG |

Overall Dimensions (Height×Width×Total Length) | 650×320×780mm |

Left-Right Positioning Center Distance | 230mm |

Front-Back Positioning Center Distance | 620mm |

Fresh Water Interface | 1.5-inch PT Male Thread |

Concentrated Water Interface | 1-inch PT Male Thread |

Water Inlet Requirement | RO product water (conductivity ≤5μS/cm) |

Product Water Quality | ≥15MΩ·CM |

Concentrated Water Recovery Rate | 85-90% |

Practical Application Cases

Case 1: An 8-inch Semiconductor Wafer Factory

Application Scenario: Ultra-pure water supply for cleaning process after wafer etching

Usage Effect: In 2023, 2 LCX-38T modules were introduced, and the water production resistivity was stable at 17.2±0.3MΩ·CM. The particle residue on the wafer surface after cleaning decreased by 40%, and the yield increased by 2.1%; the annual wastewater discharge was reduced by 1500 tons, and it was awarded the green factory certification by the local environmental protection department.

Case 2: Large-scale Vehicle Urea Production Base

Application Scenario: High-purity raw material water preparation

Usage Effect: A single equipment meets the water demand of the 5000 tons/year vehicle urea production line, and the produced water TOC is ≤10ppb, ensuring that the urea solution purity meets the standard. The product qualification rate increased from 96.5% to 99.8%, and the customer complaint rate decreased by 80%.

Working Principle

LCX-38T realizes deep desalination through the synergistic effect of "resin adsorption - electric field migration - membrane separation":

The ion exchange resin in the fresh water chamber adsorbs cations and anions in the raw water;

The DC electric field drives the directional migration of ions, with cations passing through the cation membrane into the concentrated water chamber and anions passing through the anion membrane into the concentrated water chamber;

The resin is continuously regenerated under the action of the electric field without chemical regeneration, realizing continuous and stable water production.

Applicable Industries

Semiconductor manufacturing: water for wafer cleaning and photolithography development

Photovoltaic industry: water for silicon wafer cutting and battery piece cleaning

Pharmaceutical industry: water for injection production and sterile purified water

Chemical field: water for fine chemical synthesis and catalyst preparation

Power industry: boiler make-up water and condensate polishing

Why Choose LCX-38T?

For large-scale industrial users with a daily water consumption of over 100 tons, LCX-38T has become the best choice to replace traditional mixed beds due to its characteristics of large flow, high stability, and low energy consumption. Its modular design allows flexible expansion, and a single system can support up to 8 units in parallel operation, meeting the ultra-large flow demand of 10-35m³/h while reducing the initial investment cost.

Contact Information

Official website: www.fgwater.com

Consultation hotline: +86-13646187144

E-mail: [email protected]