LCX-45T Industrial EDI Module High-Flow Ultra-Pure Water Solution for Large-Scale Operations

The LCX-45T stands as a flagship model in the LCX series, engineered specifically for large-scale industrial applications requiring high-volume ultra-pure water production. With a flow range of 4.8-5.3m³/h, this advanced Electrodeionization (EDI) module leverages cutting-edge technology to deliver consistent, high-quality water while eliminating the need for traditional chemical regeneration—making it an eco-friendly and cost-effective solution for modern industrial facilities.

Designed to meet the demands of large-scale production, the LCX-45T delivers 4.8-5.3m³/h of ultra-pure water, with the flexibility of parallel configuration for even higher throughput. This makes it ideal for supporting multiple production lines simultaneously, eliminating water supply bottlenecks in busy industrial environments.

By utilizing EDI technology, the LCX-45T completely eliminates the need for acid and alkali procurement, storage, and regeneration processes. This not only reduces operational costs but also minimizes safety risks associated with hazardous chemical handling, supporting green manufacturing initiatives.

The module consistently produces water with resistivity of 15-18MΩ·CM, with fluctuations limited to ±0.3MΩ·CM. This exceptional stability ensures reliable performance in quality-critical applications, reducing product defects and improving overall production efficiency.

Featuring a smart modular architecture, the LCX-45T allows for online maintenance with automatic flow redistribution. This innovative design ensures minimal downtime during servicing, maximizing production continuity—a critical advantage over traditional water treatment systems.

| Parameter | Details |

|---|

| Flow Range | 4.8-5.3m³/h |

| Operating Current | 2.5A (0-6A adjustable) |

| Operating Voltage | 0-550VDC |

| Maximum Power | 3KW/H |

| Shipping Weight | 140KG |

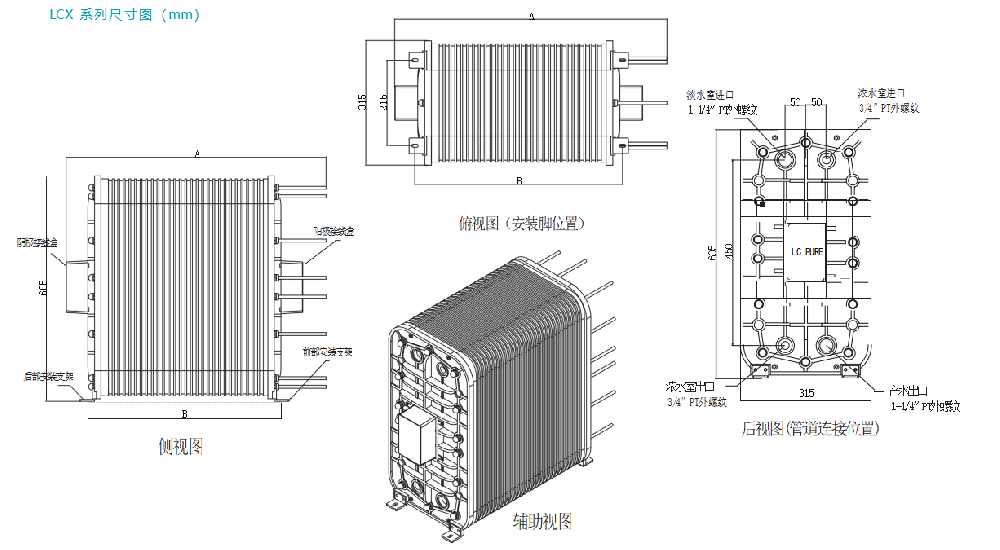

| Dimensions (H×W×Total Length A) | 605×315×945mm |

| Left-Right Positioning Center Distance | 215mm |

| Front-Back Positioning Center Distance B | 765mm |

| Fresh Water Inlet/Outlet Connector | 1-1/4″PT Male Thread |

| Concentrated Water Inlet/Outlet Connector | 3/4″PT Male Thread |

| Inlet Water Requirement | RO product water (conductivity ≤5μS/cm) |

| Product Water Quality | ≥15MΩ·CM |

A national-level electronic information park was struggling with outdated mixed-bed systems that required twice-daily regeneration, consuming large quantities of chemicals and causing production interruptions. After upgrading to 4 parallel LCX-45T units:

Achieved a combined water production capacity of 20m³/h, supporting 12 enterprises

Reduced annual chemical costs by ¥450,000

Cut wastewater discharge by 1,200 tons

Lowered product rejection rate from 1.8% to 0.2%, generating over ¥2,000,000 in additional revenue

The LCX-45T is perfectly suited for:

Large chemical industrial parks with multiple production lines

Semiconductor and electronics manufacturing facilities

High-volume automotive urea production plants

Municipal ultra-pure water supply systems

Photovoltaic and solar cell production clusters

For industrial operations requiring over 100 tons of ultra-pure water daily, the LCX-45T offers an unbeatable combination of high flow capacity, stable water quality, and low operational costs. Its scalable design allows for parallel configuration of up to 8 units, making it capable of handling peak demands of 50m³/h—providing a future-proof solution for growing industrial facilities.

Contact Us

Website: https://www.fgwater.com

Email: [email protected]

Tel: +86-13646187144