LC-5000 Industrial General-Purpose China EDI stacks The Preferred Solution for High-Capacity Ultrapure Water Preparation

Recently, many friends in the chemical and electronics industries have been asking which EDI stacks are reliable for high-capacity scenarios. Today, I would like to recommend the LC-5000 - this industrial general-purpose China EDI stacks from LC PURE. It has strong and stable water production capacity, and is particularly popular in industries such as vehicle urea purification and photovoltaics, which can fully meet the ultrapure water needs of medium and large-sized factories.

When choosing China EDI stacks, it is essential to have a clear understanding of the parameters. As an industrial general-purpose model, every parameter of the LC-5000 is designed for high-capacity scenarios. I have organized them into a table for your easy reference:

| Parameter Category | Specific Value | Remarks |

|---|

| Standard Water Production Flow | 5m³/h | Suitable for continuous water use in medium and large-sized factories |

| Maximum Water Production Flow | 5.2m³/h | No pressure to cope with short-term capacity peaks |

| Minimum Water Production Flow | 4.8m³/h | Stable operation even under low load |

| Operating Voltage | 0-550VDC | Compatible with industrial high-frequency DC power supplies |

| Operating Current | 2.5A (adjustable 0-6A) | Controllable energy consumption and low operating costs |

| Number of Membrane Pairs | 45 | High ion adsorption efficiency and fast water production |

| Operating Net Weight | 170KG | Matching load-bearing brackets are required for installation |

| Maximum Power | 3KW/H | More than 30% more energy-efficient than traditional mixed beds |

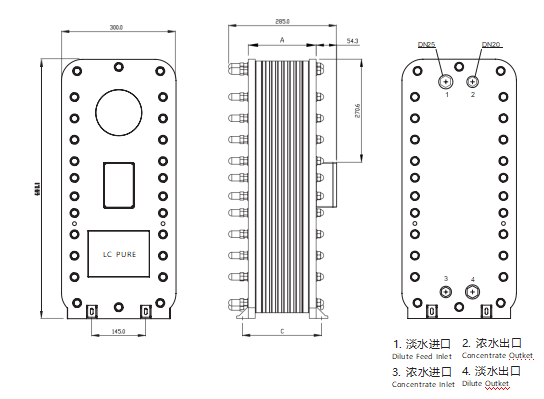

| Fresh Water Inlet/Outlet | DN25 PVC | Compatible with industrial standard pipelines, no need for pipeline modification |

| Concentrated Water Inlet/Outlet | DN20 PVC | Concentrated water can be recycled to the RO system for reuse |

| Overall Dimensions | 680mm (Height) × 300mm (Width) | Small floor space and flexible workshop layout |

| Product Water Quality | ≥15MΩ·CM | Meets the ultrapure water standards for electronics and chemical industries |

| Recovery Rate | 85-95% | High water resource utilization rate without waste |

The most convenient thing about this China EDI stacks is that it does not require frequent acid-base regeneration like traditional mixed beds. It operates fully automatically and can produce water stably, making it very suitable for factories pursuing environmental protection and efficiency.

Just talking about parameters is not enough. Let me share a real case with you. A factory in Jiangsu that produces photovoltaic modules previously used traditional mixed beds to produce ultrapure water, but encountered many problems: it had to shut down for 1-2 times a week to replace acid and alkali, the monthly wastewater treatment cost was nearly 20,000 yuan, and the water quality occasionally fluctuated, affecting the cleaning effect of photovoltaic glass.

Later, they switched to the LC-5000 China EDI stacks, and the changes were particularly obvious:

Regeneration is no longer needed! It saves a total of 28,000 yuan per month on acid-base procurement and wastewater treatment costs, which can save more than 300,000 yuan a year;

With fully automatic control, no dedicated personnel are required to monitor it 24 hours a day, allowing maintenance staff to free up time for other tasks;

The product water quality is stable at 16-18MΩ·CM, with no fluctuations in half a year, and the yield rate of photovoltaic modules has increased by 3%.

The factory director told me: "If I had known that China EDI stacks are so easy to use, I shouldn't have been stuck with traditional equipment. It's both costly and troublesome!"

Many friends are worried that EDI stacks are difficult to maintain. In fact, the LC-5000 is very easy to maintain. Just remember these 4 small tips, and even beginners can handle it:

Don't neglect daily monitoring: Check the pressure gauge (the pressure at the fresh water inlet and outlet should be 0.15MPa higher than that at the concentrated water inlet and outlet) and flowmeter (keep the flow at 4.8-5.2m³/h) every day. If the values are incorrect, adjust the control valve, which can be done in a few minutes;

Regular water quality monitoring is necessary: Use a conductivity meter to check the inlet water (≤5μS/cm) and product water resistance (≥15MΩ·CM) every week. Once the standards are exceeded, shut down the machine immediately for inspection. Do not force operation, otherwise it will easily damage the membrane stack;

Pay attention to power supply maintenance: Be sure to use a DC power supply with "one-to-one control". Check the current (2.5A) and voltage (0-550VDC) every month. In case of an alarm, cut off the power first before repairing, which is safe and reliable;

Don't waste recycled concentrated water: Concentrated water can be recycled back to the RO inlet water tank for reuse, which not only reduces emissions but also saves water. In addition, the security filter for pretreatment should be cleaned regularly to prevent oil and oxidizing substances from entering - this is the key to protecting China EDI stacks!

Absolutely! Its standard water production flow is 5m³/h, and the maximum can reach 5.2m³/h. Even short-term capacity peaks can be handled without additional equipment.

It has 45 membrane pairs, which has higher ion removal efficiency and faster water production than small-sized models. Moreover, its operating cost is low. With a power of 3KW/H, it saves about 600 kWh of electricity per month compared with equipment of the same capacity. It also does not require treatment of waste acid and alkali, complying with environmental protection policies, so there is no need to worry about environmental impact assessment issues.

No major modifications are needed! Its fresh water interface is DN25 PVC and the concentrated water interface is DN20 PVC, which can be directly compatible with the industrial pipelines of most factories. Professional installers can complete the installation in one day without delaying production.

Engineer Wang from a vehicle urea purification plant in Shandong: "We have been using the LC-5000 for nearly 2 years, and the product water quality is stable at 17MΩ·CM, which fully meets the urea purity standard. After the concentrated water is recycled, the water resource utilization rate has increased from 75% to 92%. China EDI stacks are really reliable!"

Manager Zhao from a chemical enterprise in Zhejiang: "I was worried that high-capacity EDI stacks would be expensive at first, but after calculating the account, I found that the cost can be recovered in 3 months. Now, the money saved every month can be used to buy 2 more sets of equipment. The cost-effectiveness is really high!"

In addition to the LC-5000, LC PURE has many models suitable for different scenarios, and you can choose according to your needs:

LCX Series Industrial General-Purpose: LCX-05T, LCX-10T, LCX-20T, LCX-30T, LCX-38T, LCX-45T, LCX-50T, LCX-55T (Water production: 0.4-7.3m³/h);

LCM Series Industrial General-Purpose: LCM-3T, LCM-5T (Water production: 2.8-5.3m³/h);

Laboratory MINI Series: MINI-20, MINI-60, MINI-100, MINI-150, MINI-200, MINI-250, MINI-300 (Water production: 20-300L/h);

LC Classic Series: LC-300, LC-500, LC-1000, LC-2000, LC-3000, LC-4000, LC-5000 (Water production: 0.3-5.2m³/h);

LCX-H High-Temperature Disinfection Type: LCX-05H, LCX-10H, LCX-20H, LCX-30H, LCX-38H, LCX-45H (High temperature resistance up to 60℃, can be disinfected at 85℃).

For more models, please click: https://www.fgwater.com/China-EDI-stacks/587.html