LCX-05H High Temperature Disinfection Type China EDI stacks The First Choice for Ultrapure Water Preparation Under 5-60℃ Working Conditions

Recently, many friends in the pharmaceutical and food processing industries have been asking which EDI stacks can withstand high temperatures and still produce water stably in high-temperature scenarios. Today, I must recommend the LCX-05H - this high-temperature disinfection type China EDI stacks from LC PURE. It can operate normally at 5-60℃ and even withstand high-temperature disinfection at 85℃, making it extremely popular in industries that require frequent sterilization.

When choosing high-temperature China EDI stacks, it is crucial to focus on temperature resistance and disinfection capabilities. I have organized the key parameters of the LCX-05H into a table, so you can easily compare them with your needs:

| Parameter Category | Specific Value | Remarks |

|---|

| Flow Range | 0.4-0.6m³/h | Suitable for small and medium-sized high-temperature water use scenarios |

| Operating Current | 2.5A (adjustable 0-6A) | Low energy consumption and stable operation at high temperatures |

| Operating Voltage | 0-200VDC | Compatible with industrial high-frequency DC power supplies |

| Maximum Power | 1.2KW/H | 25%+ more energy-efficient than ordinary high-temperature water treatment equipment |

| Shipping Weight | 40KG | Flexible installation, no need for heavy-duty brackets |

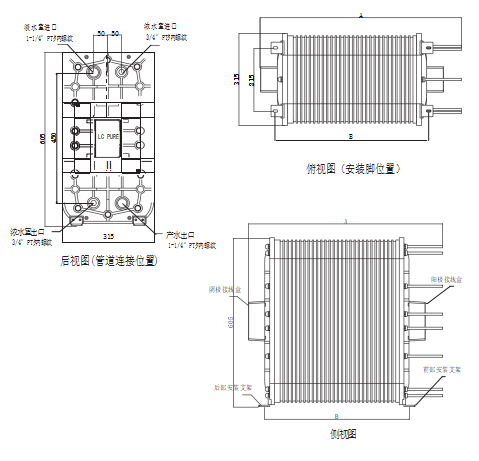

| Overall Dimensions | 605mm (Height) × 315mm (Width) | Small floor space, easy to layout in the workshop |

| Total Length A | 270mm | Suitable for compact installation spaces |

| Left-Right Positioning Center Distance | 215mm | Standardized installation holes for easy fixation |

| Front-Back Positioning Center Distance | 205mm | Convenient for pipeline connection |

| Fresh Water Inlet/Outlet Connector | 1-1/4″PT Female Thread | Good sealing, no liquid leakage at high temperatures |

| Concentrated Water Inlet/Outlet Connector | 3/4″PT Female Thread | Compatible with high-temperature pipeline specifications |

| Product Water Quality | ≥10MΩ·CM | Meets ultrapure water standards for high-temperature working conditions |

As a high-temperature China EDI stacks, the LCX-05H has clear requirements for inlet water. Only when these requirements are met can the service life and water production effect be guaranteed:

Inlet Water Source: Must be reverse osmosis (RO) product water

Inlet Conductivity: ≤10μS/cm (≤5μS/cm when containing CO₂ and silicon)

Temperature Range: 5-60℃ (up to 85℃ during disinfection)

Inlet Water Pressure: 0.1-0.3MPa

Total Chlorine Content: <0.02ppm

Iron (Fe)/Manganese (Mn)/Sulfide (S⁻): All <0.01ppm

pH Value: 7-8

Total Hardness (as CaCO₃): <0.5ppm

Total Organic Carbon (TOC): <0.5ppm

Silicon (as SiO₂): <0.5ppm

Oxidizing Substances/Oil/Fat: Not detected

During actual operation, these parameters must be closely monitored to keep the China EDI stacks in optimal condition:

Recovery Rate: 85-95% (concentrated water can be recycled to the RO system for reuse)

Maximum Inlet Water Pressure: 0.5MPa

Pressure Drop at Normal Flow: 0.1-0.3MPa

Maximum Inlet Water Temperature: 60℃

Disinfection Temperature: 85℃ (can withstand ≥150 disinfections)

Maximum Inlet Conductivity: 5μS/cm (the system will alarm and shut down if exceeded)

Let me share a real case. A pharmaceutical factory in Zhejiang that produces injections previously used ordinary EDI stacks to treat high-temperature purified water, but encountered many problems: when the temperature exceeded 35℃, water production became unstable; the equipment had to be disassembled for manual disinfection every month, which was not only troublesome but also prone to contamination, and the wastewater treatment cost was high.

After switching to the LCX-05H China EDI stacks, the situation completely changed:

It can produce water stably at 5-60℃, eliminating shutdowns due to temperature fluctuations, and increasing the production efficiency of injections by 15%;

High-temperature disinfection at 85℃ can be performed directly, and disinfection can be done 3 times a month without disassembling the equipment. This saves 2 maintenance working hours and avoids the risk of manual contamination;

Concentrated water is recycled to the RO system, increasing the water resource utilization rate from 70% to 90% and saving over 8,000 yuan in monthly wastewater treatment costs.

The workshop director told me: "If I had known that high-temperature China EDI stacks are so worry-free, I wouldn't have struggled with ordinary equipment before. It was both costly and affected production!"

Many friends are worried that EDI stacks are difficult to maintain under high-temperature conditions. In fact, as long as you pay attention to these 5 points for the LCX-05H, even beginners can handle it:

Control High-Temperature Inlet Water Quality: Before starting the machine each time, check the inlet water temperature (do not exceed 60℃) and conductivity (≤5μS/cm). If the standards are exceeded, treat the RO product water first to prevent unqualified water from entering the membrane stack;

Standardize Disinfection Operations: During disinfection at 85℃, first adjust the flow to low load. After disinfection, slowly cool down to below 60℃ before restoring the normal flow to avoid damaging the membrane due to excessive temperature difference;

Monitor Pressure and Flow Regularly: Check the pressure gauge (the pressure at the fresh water inlet and outlet is optimally 0.15MPa higher than that at the concentrated water inlet and outlet) and flowmeter (keep it at 0.4-0.6m³/h) every day. If the values are abnormal, adjust the control valve;

Do Not Neglect Power Supply Maintenance: Use a DC power supply with "one-to-one control". Check the current (2.5A) and voltage (0-200VDC) every month, and prevent the power supply from overloading in high-temperature environments;

Inspect Connector Sealing: Threaded connectors are prone to loosening at high temperatures. Gently tighten the fresh water/concentrated water connectors with a wrench every month to ensure no liquid leakage and avoid safety hazards caused by high-temperature water leakage.

Absolutely! Its normal operating temperature range is 5-60℃, and 45℃ is within the optimal working range. The product water quality can also be stably maintained at 10-12MΩ·CM, fully meeting the requirements.

Generally, after 150 disinfections, you can contact the manufacturer to test the status of the membrane stack. If only the ion exchange resin efficiency decreases, the resin can be replaced and the stack can continue to be used. There is no need to replace the entire unit, which saves a lot of costs.

No! Although the concentrated water of the LCX-05H has undergone high-temperature treatment, its ion concentration is well controlled. As long as it is cooled to the suitable temperature for the RO system (usually around 25℃) before being recycled to the RO system, it can be reused normally. This also reduces the pretreatment pressure of the RO inlet water.

Engineer Li from a food processing factory in Guangdong: "We use the LCX-05H to treat 50℃ cleaning water, and the product water quality is stably maintained at 11MΩ·CM. High-temperature disinfection at 85℃ is very convenient without disassembling the equipment. China EDI stacks are much more reliable than ordinary high-temperature water treatment equipment!"

Manager Wang from a pharmaceutical factory in Anhui: "Previously, ordinary EDI had problems at 38℃. After replacing with the LCX-05H, it has operated without faults at 40℃ for half a year, and the number of disinfections is also sufficient. We have saved nearly 100,000 yuan in maintenance costs a year. It's really worth it!"

In addition to the LCX-05H, LC PURE has models suitable for different scenarios. You can choose according to your needs:

LCX Series Industrial General-Purpose: LCX-05T, LCX-10T, LCX-20T, LCX-30T, LCX-38T, LCX-45T, LCX-50T, LCX-55T (Water production: 0.4-7.3m³/h);

LCM Series Industrial General-Purpose: LCM-3T, LCM-5T (Water production: 2.8-5.3m³/h);

Laboratory MINI Series: MINI-20, MINI-60, MINI-100, MINI-150, MINI-200, MINI-250, MINI-300 (Water production: 20-300L/h);

LC Classic Series: LC-300, LC-500, LC-1000, LC-2000, LC-3000, LC-4000, LC-5000 (Water production: 0.3-5.2m³/h);

LCX-H High-Temperature Disinfection Type: LCX-05H, LCX-10H, LCX-20H, LCX-30H, LCX-38H, LCX-45H (High temperature resistance up to 60℃, can be disinfected at 85℃).

For more models, please click: https://www.fgwater.com/China-EDI-stacks/587.html