BWC200-H Containerized Brackish Water Reverse Osmosis System

In areas where brackish water is widely distributed but fresh water resources are scarce, integrated and highly adaptable desalination equipment is key to meeting water demand. The FENIGAL BWC200-H Containerized Brackish Water Reverse Osmosis System, with a 20-foot standardized container as its carrier, integrates a full set of core components for brackish water desalination. Relying on efficient water production, easy installation and stable performance, it provides a reliable fresh water solution for small and medium-sized communities, agricultural bases, hotels and other scenarios.

As a dedicated containerized model for brackish water desalination in the Desal BWC series, the BWC200-H integrates all core modules (pretreatment, reverse osmosis, cleaning and dosing, control unit, etc.) into one 20-foot standardized container. No additional workshops or protective structures need to be built, significantly reducing on-site construction costs. Its design is based on the working condition of "4,000 ppm, 20°C brackish water", with a rated daily fresh water output of 240 cubic meters (calculated based on a rated water production flow rate of 10 m³/h and 24-hour daily operation). This capacity can meet the daily drinking water needs of approximately 1,000 people or support medium-sized agricultural irrigation.

Rapid Installation and Commissioning: Over 90% of the installation work is completed in the factory. On-site operations only require connecting the water inlet, power supply and drainage pipelines, greatly shortening the commissioning cycle and avoiding the lengthy on-site construction of traditional systems.

Strong Corrosion Resistance: High-pressure pipelines and fittings are made of Sch10 SS316 stainless steel, and the container and frame are coated with heavy-duty marine paint. This enables the system to withstand brackish water erosion for a long time and extend the service life of the equipment.

Low-Energy Operation: Equipped with a high-efficiency high-pressure pump, IE3-class energy-saving motor and low-energy reverse osmosis membrane, the energy consumption per unit of water production is only 1.56 kWh/m³, which is lower than the average level of similar brackish water desalination equipment in the industry.

Easy Maintenance and Rapid Recovery: Standardized general parts are adopted. In case of failure, the system can be quickly restored to operation by replacing parts, reducing downtime losses. At the same time, it is equipped with three-stage filtration (sand filtration, pre-filtration, main filtration) to effectively protect the high-pressure pump and reverse osmosis membrane.

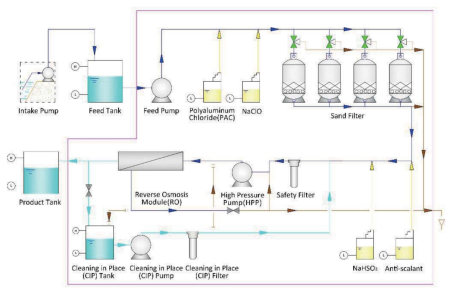

The BWC200-H adopts a mature reverse osmosis (RO) process, converting brackish water into fresh water that meets drinking water standards through a closed-loop process of "water intake - pretreatment - high-pressure desalination - product water storage". The specific flow is as follows :

Water Intake and Storage: Brackish water is pumped by an Intake Pump and sent to a Feed Tank to balance the flow and pressure, preventing water inlet fluctuations from affecting system stability.

Pretreatment and Purification:

The Feed Pump pressurizes the water, and at the same time, Poly Aluminium Chloride (PAC) is dosed to flocculate impurities and Sodium Hypochlorite (NaClO) is dosed for sterilization.

The water flows through a Sand Filter to remove particulate impurities (the Sand Filter can be omitted if the feed water turbidity is less than 0.3 NTU).

Sodium Bisulfite (NaHSO₃) is dosed to remove residual chlorine, and an Anti-scalant is dosed to prevent membrane scaling. Finally, the water passes through a Safety Filter to trap tiny impurities, protecting the subsequent high-pressure pump and membrane modules.

Reverse Osmosis Desalination: The High-Pressure Pump (HPP) pressurizes the pretreated water to 20 barg (maximum system pressure) and sends it to the 8040-type reverse osmosis membrane modules. Water molecules pass through the membrane to form fresh water, while high-salinity concentrated water is discharged after pressure relief.

Product Water and Maintenance: Fresh water is stored in a Product Tank for later use; the system is equipped with a Cleaning in Place (CIP) device to regularly clean the membrane modules and maintain desalination efficiency.

The following parameters are designed based on "4000 ppm, 20℃ brackish water":

| Technical Parameter | Unit | BWC200-H Configuration | Remarks |

|---|

| Rated Product Flow | m³/h | 10 | Corresponding to a daily output of 240 m³; the output can be slightly increased when the feed water TDS is lower than 4,000 ppm |

| Rated Product Flow | L/S | 2.78 | - |

| Rated Recovery Rate | % | 70 | 70% of the feed water is converted into fresh water, and 30% is discharged as concentrated water; the recovery rate can be customized and adjusted according to needs |

| Rated Feed Flow | m³/h | 14.29 | Calculated to match the recovery rate, ensuring stable operation of the system |

| Maximum System Pressure | barg | 20 | The normal operating pressure must be higher than this value; versions with higher pressure can be customized for high-TDS feed water scenarios |

| RO Membrane Specification | inch | 8040 | Industry-standard membrane type, easy to replace |

| Quantity of RO Membranes | pcs | 12 | Membrane modules are designed in series/parallel to ensure desalination efficiency and water production stability |

| Dry Weight of Equipment | ton | 6 | Does not include operating water in the system, facilitating transportation and on-site hoisting |

| Container Size | ft | 20 | Standard 20-foot container, suitable for sea, land and other transportation methods |

| Rated Power (Core Equipment) | kW | 15.6 | Includes power of feed pump, high-pressure pump, CIP pump and dosing pump; excludes power of intake pump and air conditioner |

| Energy Consumption per Unit Product Water | kWh/m³ | 1.56 | Low-energy design, controllable long-term operating costs |

| Installed Power (Including Auxiliary Equipment) | kW | 30.2 | Includes core equipment + lighting; a power supply line matching the corresponding power is required |

| Power Input | - | 3PH, 380VAC±10%, 50Hz | Three-phase AC power; versions with other voltages/frequencies can be customized according to regional needs |

BWC200-H has clear restrictions on the quality of influent water. If it exceeds the specified range, additional pre-treatment is required. The effluent fully complies with WHO drinking water standards. The specific parameters are as follows:

| Category | Indicator | Requirement | Remarks |

|---|

| Feed Water Standards | Salinity (TDS) | 1,000-5,000 mg/L | Contact the manufacturer for customized pretreatment solutions if the range is exceeded |

| Temperature | 5-35°C | Heating/cooling devices need to be matched for abnormal temperatures to avoid affecting membrane efficiency |

| Turbidity | <40 NTU | Additional pretreatment such as a sedimentation tank is required if turbidity >40 NTU |

| Chemical Oxygen Demand (COD) | <10 mg/L | Prevents organic matter from contaminating membrane modules and affecting desalination efficiency |

| Ferrous (Fe²⁺) | <0.1 mg/L | Avoids iron ion deposition on the membrane surface and reduces membrane flux |

| Manganese (Mn²⁺) | <0.1 mg/L | Same as ferrous ions, prevents membrane scaling |

| Oil and Grease | 0 mg/L | Grease can permanently damage reverse osmosis membranes and must be strictly controlled |

| Product Water Standards (Drinking Water) | Salinity (TDS) | <500 mg/L | Meets WHO "Guidelines for Drinking Water Quality" (4th edition, 2012) |

| pH Value | 6-8 | A mild pH range suitable for human drinking, with no irritation |

| Turbidity | <0.2 NTU | Clear water quality with no visible suspended impurities |

With its flexibility and adaptability, the BWC200-H can cover a variety of brackish water desalination demand scenarios:

Small and Medium-Sized Communities/Towns: Provides daily drinking water for villages and suburban communities far from municipal water supply.

Agricultural Planting Bases: Treats underground brackish water to provide fresh water that meets irrigation standards for cash crops, fruits and vegetables.

Hotels/Resorts: Meets the domestic water and service water needs of accommodation facilities in coastal or inland brackish water areas.

Mining Camps: Provides stable fresh water for the staff living areas of remote mining areas, ensuring the normal operation of production and life.

The BWC200-H model and supporting kit codes are clearly marked, facilitating accurate purchasing:

| Item | Specific Content | Description |

|---|

| System Model | BWC200-H | Containerized brackish water reverse osmosis system, 20-foot container specification |

| System Code Number | 204A105 | Unique internal identifier of the manufacturer, used for order confirmation, production tracking and after-sales docking |

| Filter Kit Code Number | 244P005 | Includes filter elements for 1 year of use; additional procurement is required if the feed water has high turbidity or many impurities |

| Insulation Kit Code Number | 254P003 | Includes container insulation layer and air conditioner, suitable for high-temperature/low-temperature areas to prevent temperature from affecting membrane efficiency |

If the equipment operates in strict accordance with the specifications in the Operation Manual, the manufacturer provides a dual warranty:

For inquiries about technical details, customization needs or procurement, please contact us through the following methods:

Landline: +86 0510 85163211

Mobile: +86 13646187144

Address: Room 511, Block B, 100 Dicui Road, Binhu, Wuxi, Jiangsu, China

Official Website: www.fgwater.com

Email:[email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system