BWC1000 Containerized Brackish Water Reverse Osmosis System

The Desal BWC1000 Containerized Brackish Water Reverse Osmosis System is a high-efficiency container-integrated desalination solution developed by FENIGAL. It integrates core components such as pretreatment, reverse osmosis (RO) membranes, and high-pressure pumps into a 40-foot standard container. Most installation and commissioning work is completed before delivery, enabling quick on-site deployment with only simple water, electricity, and pipeline connections.

Tailored for brackish water with a salinity of 1,000–5,000 mg/L, the system has a rated fresh water production capacity of 42 m³/h. Its produced water meets the standards of the WHO Guidelines for Drinking Water Quality (4th Edition, 2012), making it ideal for scenarios like urban water supply supplementation, large-scale mining operations, power plant auxiliary water, and hotel/resort centralized water supply—effectively solving clean water shortages in brackish water-affected areas.

| Technical Indicator | Unit | BWC1000 Parameter Value | Remarks |

|---|

| Rated Product Flow ¹ | m³/h | 42 | Based on designed feed water (4,000 ppm salinity, 20℃); contact us for customization under other conditions |

| Rated Product Flow (Converted) | L/s | 11.67 | - |

| Rated Recovery Rate ¹ | % | 70 | Standard recovery rate for brackish water desalination; adjustable on demand |

| Rated Feed Flow | m³/h | 60 | Designed to match the processing capacity of RO membrane components |

| Max System Pressure ² | barg | 20 | Normal operating pressure > minimum system pressure; higher pressure available via customization |

| RO Membrane Specification | Inch | 8040 | Industrial standard 8-inch diameter, 40-inch length membrane elements |

| RO Membrane Quantity | pcs | 50 | Optimal configuration to balance water production efficiency and desalination performance |

| Dry Weight ³ | ton | 16 | Excludes weight of operating water or other liquids |

| Container Size | ft | 40 | Standard 40-foot container for easy transportation and on-site placement |

| Rated Power ⁴ | kW | 44.4 | Includes power of feed pump, high-pressure pump (HPP), CIP pump, etc.; excludes intake pump and product water distribution pump |

| Energy Consumption ⁴ | kWh/m³ | 1.06 | Low energy consumption enabled by IE3 motors and energy-saving RO membranes |

| Installed Power ⁵ | kW | 70.7 | Total power of core pumps, CIP system, dosing pumps, and lighting |

| Power Input | - | 3PH, 380V AC±10%, 50Hz | Compatible with industrial standard three-phase power supply |

(Data source: "Technical specifications" chapter in the document; ¹²³⁴⁵ correspond to notes in the document for detailed explanation)

| Water Quality Indicator | Unit | Limit | Abnormal Handling Suggestions |

|---|

| Salinity (TDS) | mg/L | 1,000–5,000 | Contact us for customized pretreatment if salinity is out of range |

| Temperature | ℃ | 5–35 | Avoid low temperature (reduces water production) or high temperature (accelerates membrane aging) |

| Turbidity | NTU | <40 | Add extra pretreatment (e.g., coagulation) if turbidity exceeds limit |

| Chemical Oxygen Demand (COD) | mg/L | <10 | Prevent organic fouling of RO membranes |

| Ferrous Iron (Fe²⁺) | mg/L | <0.1 | Avoid iron deposition and membrane scaling |

| Manganese (Mn²⁺) | mg/L | <0.1 | Prevent manganese oxidation and membrane flux reduction |

| Oil and Grease | mg/L | 0 | Strictly control oil content to avoid permanent membrane damage |

| Water Quality Indicator | Unit | Limit | Compliance Basis |

|---|

| Salinity (TDS) | mg/L | <500 | Meets WHO Guidelines for Drinking Water Quality (4th Edition, 2012) |

| pH Value | - | 6–8 | Ensures drinking comfort and pipeline corrosion resistance |

| Turbidity | NTU | <0.2 | Clear water with no visible suspended solids |

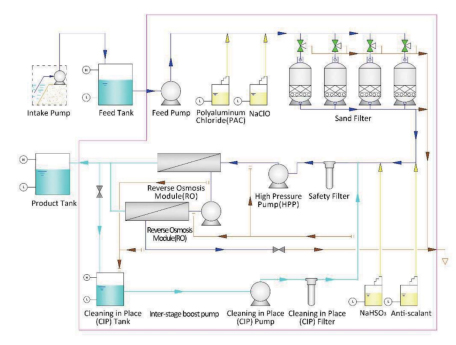

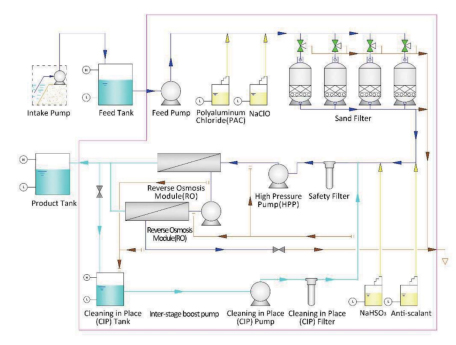

Intake Pump → Feed Tank → Feed Pump → (Dosing: Sodium Hypochlorite for disinfection) → Sand Filter (omittable if feed water turbidity <0.3 NTU) → (Dosing: Sodium Bisulfite + Antiscalant for residual chlorine removal & scale prevention) → Security Filter → High-Pressure Pump → RO Unit (fresh water permeates membrane; concentrated brine discharged after pressure relief) → Product Tank

Rapid Deployment: Over 80% of installation is completed before delivery; on-site installation time is only 30% of traditional systems (per document comparison data), significantly shortening project cycles.

Strong Corrosion Resistance: Uses Sch10 SS316 high-pressure pipes/fittings and heavy-duty anti-corrosion paint; wet components are made of duplex steel, SS904L, or UPVC to resist brackish water erosion.

Efficient Filtration Protection: Three-stage filtration (sand filter → security filter → main filter) effectively removes impurities, protecting high-pressure pumps and RO membranes and reducing maintenance costs.

Low Energy Consumption: Equipped with high-efficiency HPP, IE3 motors, and low-energy RO membranes, achieving an energy consumption of only 1.06 kWh/m³—lower than industry average levels.

Easy Maintenance: Adopts standard parts; in case of malfunctions, the system can be quickly restored (per document "Fast restoring" feature), minimizing downtime.

Urban & Small-City Water Supply: Supplements water sources in areas with brackish groundwater.

Mining Operations: Provides drinking water for mining teams and water for mining processes.

Power Plants: Supplies low-salinity water for boiler feed water or cooling towers.

Hotels & Resorts: Meets large-scale concentrated water demand for guests and operations.

Agricultural Exploitations: Provides qualified irrigation water in arid, brackish water-rich regions.

| System Model | System Code | Filter Kit Code | Insulation Kit Code |

|---|

| BWC1000-H (Heated) | 204A109 | 244P009 | 254P007 |

| BWC1000 (Standard) | 204A009 | 244P009 | 254P007 |

Filter Kit: Contains filter elements for 1 year of use; extra kits needed if feed water pollution is severe.

Insulation Kit: Includes heat insulation layer and air conditioner, suitable for extreme temperature environments.

Under proper operation per the Operational Manual, FENIGAL provides a 12-month warranty (starting from commissioning date) or a maximum of 18 months from the production date (per document "Warranty" chapter).

System Process Diagram:

Product Appearance Image:

Core Component Image:

FENIGAL Science and Technology (Wuxi) Co., Ltd.

Tel: +86 0510 85163211

Mobile: +86 13646187144

Address: Room 511, Block B, 100 Dicui Road, Binhu District, Wuxi, Jiangsu, China

Website: www.fgwater.com

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system