BWC2000 Containerized Brackish Water Reverse Osmosis System

The Desal BWC2000 Containerized Brackish Water Reverse Osmosis System is a large-capacity, integrated desalination solution independently developed by FENIGAL. It adopts a dual-container configuration (two 40-foot standard containers) to integrate all core components—including pretreatment modules, high-efficiency reverse osmosis (RO) membrane groups, high-pressure pump units, and intelligent control systems.

Most installation and commissioning work is completed in the factory, so only simple on-site connections (water pipes, power lines, and signal lines) are required to put the system into operation quickly. Designed for brackish water with a salinity of 1,000–5,000 mg/L, the system has a rated fresh water production capacity of 85 m³/h, and its produced water fully complies with the WHO Guidelines for Drinking Water Quality (4th Edition, 2012). It is mainly applicable to large-scale water demand scenarios such as urban centralized water supply, large industrial enterprises (e.g., power plants, petrochemicals), and large mining areas, effectively solving the problem of clean water shortage in brackish water-rich regions.

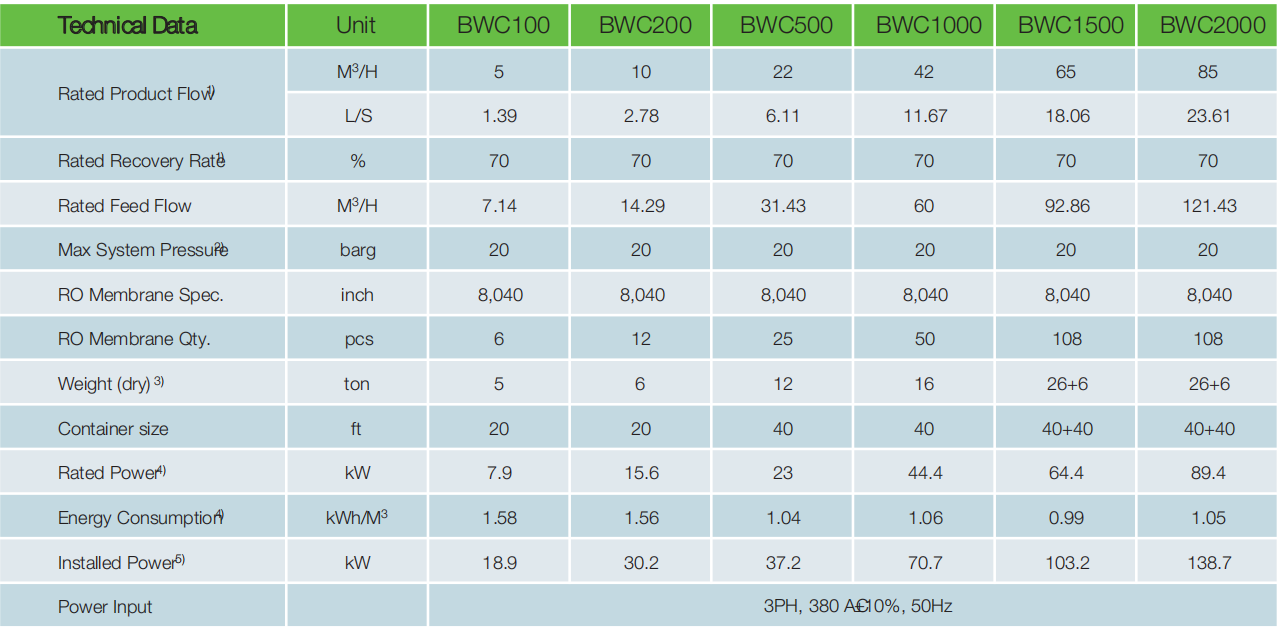

| Technical Indicator | Unit | BWC2000 Parameter Value | Remarks |

|---|

| Rated Product Flow | m³/h | 85 | Based on designed feed water conditions (4,000 ppm salinity, 20℃); contact FENIGAL for customization if feed water conditions differ |

| Rated Product Flow (Converted) | L/s | 23.61 | - |

| Rated Recovery Rate | % | 70 | Standard recovery rate for brackish water desalination; adjustable according to actual water quality requirements |

| Rated Feed Flow | m³/h | 121.43 | Matches the processing capacity of 108 RO membrane elements to ensure stable operation |

| Max System Pressure | barg | 20 | Normal operating pressure must be higher than the minimum system pressure; higher pressure versions can be customized on demand |

| RO Membrane Specification | Inch | 8040 | Industrial standard 8-inch diameter, 40-inch length RO membrane elements (mature and reliable in performance) |

| RO Membrane Quantity | pcs | 108 | Optimal configuration to balance high water production efficiency and long-term stable desalination |

| Dry Weight | ton | 26+6 | Total dry weight of two containers, excluding weight of operating water, cleaning agents, and other liquids |

| Container Size | ft | 40+40 | Two 40-foot standard containers (easy to transport by land/sea; flexible on-site placement) |

| Rated Power | kW | 89.4 | Includes power of feed pump, high-pressure pump (HPP), CIP (Clean-in-Place) pump, and dosing pumps; excludes intake pump and product water distribution pump |

| Energy Consumption | kWh/m³ | 1.05 | Low energy consumption achieved by matching high-efficiency IE3 motors and low-energy RO membranes |

| Installed Power | kW | 138.7 | Total power of all functional modules, including core pumps, control system, and lighting |

| Power Input | - | 3PH, 380V AC±10%, 50Hz | Compatible with global industrial standard three-phase power supply; no additional transformer required for most regions |

| Water Quality Indicator | Unit | Limit | Abnormal Handling Suggestions |

|---|

| Salinity (TDS) ¹ | mg/L | 1,000–5,000 | If salinity exceeds the range, contact FENIGAL to customize advanced pretreatment (e.g., multi-stage filtration) |

| Temperature | ℃ | 5–35 | Avoid water temperature <5℃ (reduces membrane flux) or >35℃ (accelerates membrane aging); add heat exchange module if needed |

| Turbidity ² | NTU | <40 | If turbidity >40 NTU, add coagulation and sedimentation units to prevent membrane fouling |

| Chemical Oxygen Demand (COD) | mg/L | <10 | Control COD to avoid organic matter adhering to the membrane surface and blocking pores |

| Ferrous Iron (Fe²⁺) | mg/L | <0.1 | Remove excess Fe²⁺ via aeration or chemical oxidation to prevent iron scale formation |

| Manganese (Mn²⁺) | mg/L | <0.1 | Excess Mn²⁺ will cause membrane discoloration and flux decline; use manganese sand filter for removal |

| Oil and Grease | mg/L | 0 | Strictly control oil content (even trace oil will permanently damage RO membranes); add oil-water separation unit if needed |

| Water Quality Indicator | Unit | Limit | Compliance Basis & Application Scenarios |

|---|

| Salinity (TDS) ³ | mg/L | <500 | Meets WHO Guidelines for Drinking Water Quality (4th Edition, 2012); can be used directly as drinking water or industrial process water |

| pH Value | - | 6–8 | Neutral range, no corrosion to water supply pipelines; suitable for long-term storage |

| Turbidity | NTU | <0.2 | Water is clear and transparent, with no visible suspended solids; meets high standards for food, beverage, and pharmaceutical industries |

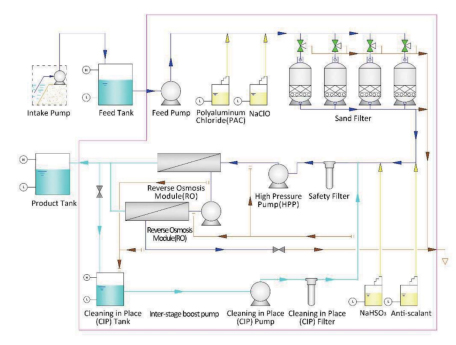

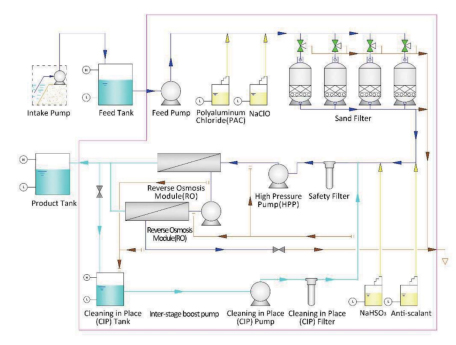

Intake Pump → Feed Tank (water storage and buffering) → Feed Pump → (Dosing: Sodium Hypochlorite, disinfection to kill microorganisms) → Sand Filter (removes suspended solids; omittable if feed water turbidity <0.3 NTU) → (Dosing: Sodium Bisulfite, removes residual chlorine; Antiscalant, prevents scale formation) → Security Filter (filters particles >5μm to protect high-pressure pump and RO membrane) → High-Pressure Pump (provides pressure for RO desalination) → RO Unit (fresh water permeates the membrane; concentrated brine is discharged after pressure relief) → Product Tank (stores qualified fresh water)

Ultra-Fast Deployment: Over 90% of installation is completed in the factory; on-site installation time is only 30% of that of traditional desalination systems (per the document’s "Feature comparison table"), and the system can be commissioned and put into use within 1 week after container arrival.

Strong Corrosion Resistance: High-pressure pipes and fittings use Sch10 SS316 stainless steel (excellent corrosion resistance to brackish water); container frames and internal supports are coated with heavy-duty marine anti-corrosion paint, ensuring a service life of >10 years in harsh environments.

Triple Filtration Protection: The "sand filter + security filter + RO membrane" three-stage filtration system fully removes impurities of different particle sizes, reducing membrane cleaning frequency by 50% compared to similar products and extending membrane service life to 3–5 years.

Low Energy & Cost: With an energy consumption of only 1.05 kWh/m³, it saves 20–30% of energy compared to traditional RO systems; the dual-container design reduces civil engineering costs by 86% (per the document’s comparison data), significantly lowering overall project investment.

Easy Maintenance & Upgrade: All components use international standard parts (easy to purchase and replace); remote monitoring sensors and automatic cleaning systems can be added according to customer needs to realize intelligent operation and reduce manual intervention.

Urban Centralized Water Supply: Supplementary water source for cities with insufficient surface water and high groundwater salinity, solving the problem of 100,000+ residents’ drinking water.

Large Power Plants: Provides low-salinity water for boiler feed water and cooling towers, ensuring stable operation of thermal power units and reducing scaling in heat exchange equipment.

Large Mining Areas: Supplies drinking water for mining teams and process water for mineral processing, supporting continuous production of large mines with 5,000+ employees.

Coastal Resorts & Hotels: Meets large-scale water demand for guest rooms, catering, and landscaping in integrated resorts, avoiding dependence on expensive municipal water supply.

Agricultural Large-Scale Irrigation: Desalinates brackish water in arid coastal areas to provide qualified irrigation water for cash crops (e.g., fruits, vegetables), improving crop yield and quality.

| System Model | System Code | Filter Kit Code | Insulation Kit Code |

|---|

| BWC2000-H (Heated) | 204A111 | 244P011 | 254P007 |

| BWC2000 (Standard) | 204A011 | 244P011 | 254P007 |

Filter Kit: Contains all filter elements required for 1 year of normal operation; if feed water pollution is severe (e.g., high turbidity, high organic matter), it is recommended to purchase 2–3 sets at one time.

Insulation Kit: Includes container insulation layer and air conditioning system, suitable for cold regions (temperature <0℃) or high-temperature regions (temperature >35℃) to ensure stable system operation in extreme weather.

Under the condition that the equipment is operated in strict accordance with the Operational Manual (provided with the system), FENIGAL provides a 12-month warranty (starting from the date of successful commissioning) or a maximum of 18 months from the date of factory shipment (whichever comes first). The warranty covers manufacturing defects of core components (RO membranes, high-pressure pumps, etc.), but does not cover damage caused by improper operation or natural disasters.

System Process Diagram:

Product Appearance Image:

Internal Component Image:

Parameter Label Image:

FENIGAL Science and Technology (Wuxi) Co., Ltd.

Tel: +86 0510 85163211

Mobile: +86 13646187144

Address: Room 511, Block B, 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, China

Official Website: www.fgwater.com

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system