BWC1500 Containerized Brackish Water Reverse Osmosis System

The Desal BWC1500 Containerized Brackish Water Reverse Osmosis System is a large-capacity, integrated desalination solution developed by FENIGAL for brackish water treatment. It adopts a dual-container design (two 40-foot standard containers) to house core components—including pretreatment units, high-efficiency reverse osmosis (RO) membranes, high-pressure pumps, and control systems. Most installation and commissioning work is completed before delivery, allowing on-site deployment within a short period via simple connections of water, electricity, and pipelines.

Tailored for brackish water with a salinity of 1,000–5,000 mg/L, the system has a rated fresh water production capacity of 65 m³/h. Its produced water meets the standards of the WHO Guidelines for Drinking Water Quality (4th Edition, 2012), making it suitable for large-scale scenarios such as urban water supply supplementation, industrial water demand (e.g., power plants), and centralized water supply for mining areas or large resorts—effectively addressing clean water shortages in brackish water-affected regions.

| Technical Indicator | Unit | BWC1500 Parameter Value | Remarks |

|---|

| Rated Product Flow ¹ | m³/h | 65 | Based on designed feed water conditions (4,000 ppm salinity, 20℃); contact us for customization under other conditions |

| Rated Product Flow (Converted) | L/s | 18.06 | - |

| Rated Recovery Rate | % | 70 | Standard recovery rate for brackish water desalination; adjustable on demand |

| Rated Feed Flow | m³/h | 92.86 | Designed to match the processing capacity of RO membrane components |

| Max System Pressure | barg | 20 | Normal operating pressure must be higher than the minimum system pressure; higher pressure versions available via customization |

| RO Membrane Specification | Inch | 8040 | Industrial standard 8-inch diameter, 40-inch length membrane elements |

| RO Membrane Quantity | pcs | 108 | Optimal configuration to balance high water production efficiency and stable desalination performance |

| Dry Weight | ton | 26+6 | Excludes weight of operating water or other liquids; total dry weight of two containers |

| Container Size | ft | 40+40 | Two 40-foot standard containers for easy transportation and on-site placement |

| Rated Power | kW | 64.4 | Includes power of feed pump, high-pressure pump (HPP), CIP (Clean-in-Place) pump, and dosing pumps; excludes intake pump and product water distribution pump |

| Energy Consumption | kWh/m³ | 0.99 | Low energy consumption achieved via high-efficiency IE3 motors and energy-saving RO membranes |

| Installed Power | kW | 103.2 | Total power of core pumps, CIP system, dosing pumps, and lighting equipment |

| Power Input | - | 3PH, 380V AC±10%, 50Hz | Compatible with industrial standard three-phase power supply |

| Water Quality Indicator | Unit | Limit | Abnormal Handling Suggestions |

|---|

| Salinity (TDS) | mg/L | 1,000–5,000 | Contact FENIGAL for customized pretreatment solutions if salinity is out of range |

| Temperature | ℃ | 5–35 | Avoid low temperature (which reduces water production) or high temperature (which accelerates membrane aging) |

| Turbidity | NTU | <40 | Add extra pretreatment (e.g., coagulation and sedimentation) if turbidity exceeds the limit |

| Chemical Oxygen Demand (COD) | mg/L | <10 | Prevent organic matter from fouling RO membranes and affecting desalination rate |

| Ferrous Iron (Fe²⁺) | mg/L | <0.1 | Avoid iron ion deposition on the membrane surface to form scale |

| Manganese (Mn²⁺) | mg/L | <0.1 | Prevent manganese oxidation and adhesion to the membrane, which reduces flux |

| Oil and Grease | mg/L | 0 | Strictly control oil content to avoid permanent damage to membrane elements |

| Water Quality Indicator | Unit | Limit | Compliance Basis |

|---|

| Salinity (TDS) | mg/L | <500 | Meets the WHO Guidelines for Drinking Water Quality (4th Edition, 2012) |

| pH Value | - | 6–8 | Ensures human drinking comfort and prevents pipeline corrosion |

| Turbidity | NTU | <0.2 | Water is clear and free of visible suspended solids |

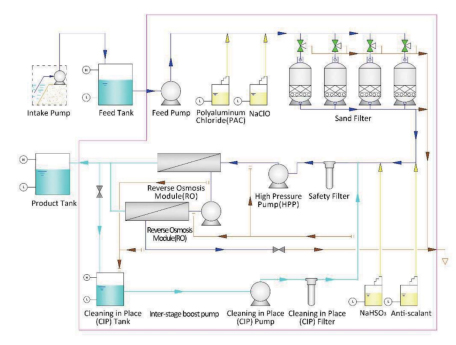

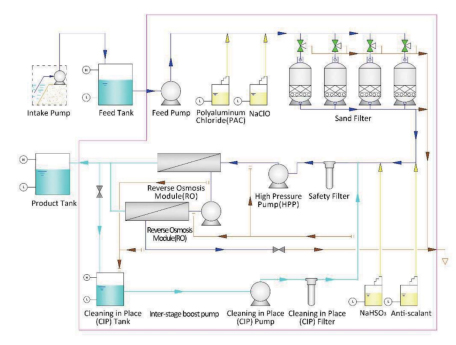

Intake Pump → Feed Tank → Feed Pump → (Dosing: Sodium Hypochlorite for disinfection) → Sand Filter (omittable if feed water turbidity <0.3 NTU) → (Dosing: Sodium Bisulfite + Antiscalant for residual chlorine removal and scale prevention) → Security Filter → High-Pressure Pump → RO Unit (fresh water permeates the membrane; concentrated brine is discharged after pressure relief) → Product Tank

(Process diagram location: "Desal BWC500 - 2000" process flow chart in the document Desal BWC series Containerized BWRO system (苦咸水的 可用数据 做一些单页).pdf; key links such as dosing points and filter units are marked in the diagram)

Rapid Deployment: Over 80% of installation is completed before delivery; on-site installation time is only 30% of that of traditional desalination systems (per the document’s comparison data), significantly shortening project cycles.

Strong Corrosion Resistance: Adopts Sch10 SS316 high-pressure pipes and fittings, and the container frame is coated with heavy-duty marine anti-corrosion paint; wet-contact components are made of duplex steel, SS904L, or UPVC to resist long-term erosion by brackish water.

Efficient Filtration Protection: Three-stage filtration (sand filter → security filter → main filter) effectively removes impurities, protecting high-pressure pumps, energy recovery devices, and RO membranes—reducing maintenance frequency and costs.

Ultra-Low Energy Consumption: Equipped with high-efficiency high-pressure pumps, IE3 energy-saving motors, and low-energy RO membranes, achieving an energy consumption of only 0.99 kWh/m³, which is lower than the industry average.

Fast Fault Recovery: Uses standard parts; in case of malfunctions, the system can be quickly restored (per the document’s "Fast restoring" feature), minimizing downtime.

Customizable Upgrades: Sensors can be added according to customer needs to realize remote data collection and operational consulting services (per the document’s "Upgrade on demand" feature).

Urban & Small-City Water Supply: Supplements municipal water sources in areas with brackish groundwater, alleviating water supply pressure.

Power Plants: Provides low-salinity water for boiler feed water or cooling tower circulation, ensuring stable industrial operation.

Large-Scale Mining Areas: Supplies drinking water for mining teams and process water for mining operations, supporting continuous production.

Large Resorts & Hotels: Meets concentrated water demand for guest rooms, catering, and landscaping, improving service quality.

Agricultural Large-Scale Exploitations: Provides qualified irrigation water in arid, brackish water-rich regions, promoting crop growth.

| System Model | System Code | Filter Kit Code | Insulation Kit Code |

|---|

| BWC1500-H (Heated) | 204A110 | 244P010 | 254P007 |

| BWC1500 (Standard) | 204A010 | 244P010 | 254P007 |

Filter Kit: Contains filter elements for 1 year of normal use; additional kits are required if feed water has high turbidity or organic matter content (per the document’s note).

Insulation Kit: Includes a heat insulation layer and air conditioner, suitable for high-temperature or low-temperature environments to ensure stable system operation.

Under the condition that the equipment is operated in strict accordance with the specifications in the Operational Manual (provided with the system), FENIGAL provides a 12-month warranty (starting from the date of commissioning) or a maximum of 18 months from the date of production (per the "Warranty" chapter in the document).

System Process Diagram:

Product Appearance & Internal Layout Images:

Core Component Detail Image:

FENIGAL Science and Technology (Wuxi) Co., Ltd.

Tel: +86 0510 85163211

Mobile: +86 13646187144

Address: Room 511, Block B, 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, China

Official Website: www.fgwater.com

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system