BWC500 Containerized Brackish Water Reverse Osmosis System

The Desal BWC500 Containerized Brackish Water Reverse Osmosis System is a standardized container-integrated desalination equipment launched by FENIGAL. Its core components are all installed in a 40-foot container, with most installation and commissioning completed before delivery. Only simple on-site connection is required for quick put-into-use.

Designed for brackish water with a salinity of 1,000-5,000 mg/L, the system has a rated fresh water production capacity of 22 m³/h. The produced water quality complies with the WHO Guidelines for Drinking Water Quality (4th Edition, 2012). It can be widely used in scenarios such as urban water supply, mining operations, agricultural irrigation, and hotel resorts, effectively addressing the clean water demand in brackish water areas.

| Technical Indicator | Unit | BWC500 Parameter Value | Remarks |

|---|

| Rated Product Flow | m³/h | 22 | Based on designed feed water conditions (4,000 ppm salinity, 20℃ water temperature; custom adjustment required for other working conditions, contact the manufacturer) |

| Rated Product Flow (Converted) | L/s | 6.11 | - |

| Rated Recovery Rate | % | 70 | Standard recovery rate for brackish water desalination; can be optimized according to actual water quality |

| Rated Feed Flow | m³/h | 31.43 | Designed feed water scale matching the processing capacity of membrane elements |

| Maximum System Pressure | barg | 20 | Normal operating pressure must be higher than the minimum system pressure; higher pressure versions can be customized on demand |

| RO Membrane Specification | Inch | 8040 | Industrial standard membrane element (8 inches in diameter, 40 inches in length) |

| RO Membrane Quantity | Piece(s) | 25 | Optimal configuration to ensure water production efficiency and desalination effect |

| Dry Weight of Equipment (Excluding Water) | Ton(s) | 12 | Equipment weight only; excluding weight of operating water or other liquids |

| Container Size | Feet | 40 | Standard 40-foot container for easy transportation and on-site deployment |

| Rated Power | kW | 23 | Includes power of core equipment such as feed pump, high-pressure pump, and CIP (Clean-in-Place) pump; excluding power of intake pump and product water transfer pump |

| Energy Consumption per Unit Product Water | kWh/m³ | 1.04 | Achieves industry-leading low energy consumption with high-efficiency IE3 motor and low-energy RO membrane |

| Installed Power | kW | 37.2 | Total power of core pump sets, cleaning system, and lighting equipment |

| Power Input | - | 3PH, 380V AC±10%, 50Hz | Compatible with industrial standard three-phase power supply, meeting power demand of most on-site conditions |

| Water Quality Indicator | Unit | Limit | Suggestions for Abnormal Conditions |

|---|

| Salinity (TDS) ¹ | mg/L | 1,000-5,000 | Contact the manufacturer for customized pretreatment solutions if the range is exceeded |

| Temperature | ℃ | 5-35 | Avoid low temperature (which reduces water production) or high temperature (which accelerates membrane aging) |

| Turbidity ² | NTU | <40 | Additional pretreatment (e.g., coagulation, sedimentation) is required if turbidity exceeds the limit |

| Chemical Oxygen Demand (COD) | mg/L | <10 | Prevent organic matter from fouling the RO membrane and affecting desalination rate |

| Ferrous Iron (Fe²⁺) | mg/L | <0.1 | Avoid iron ion deposition on the membrane surface to form scale |

| Manganese (Mn²⁺) | mg/L | <0.1 | Prevent manganese from adhering to the membrane surface after oxidation and reducing membrane flux |

| Oil and Grease | mg/L | 0 | Oil will permanently damage membrane elements; strictly control oil content in feed water |

| Water Quality Indicator | Unit | Limit | Compliance Basis |

|---|

| Salinity (TDS) ³ | mg/L | <500 | Complies with the WHO Guidelines for Drinking Water Quality (4th Edition, 2012) |

| pH Value | - | 6-8 | Meets human drinking comfort and pipeline anti-corrosion requirements |

| Turbidity | NTU | <0.2 | Clear water quality without visible suspended solids |

(Note: ¹ ² ³ correspond to the notes on water quality standards in the document; abnormal water quality must be handled as required)

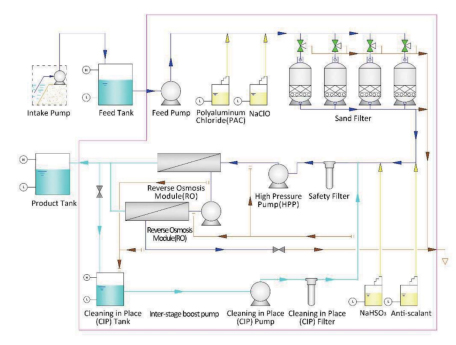

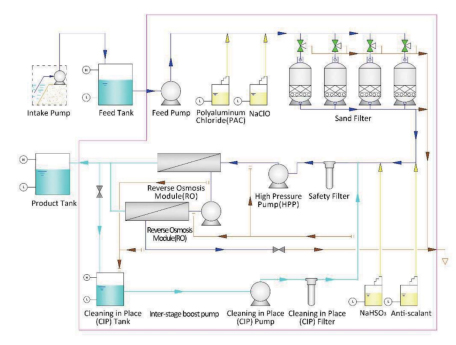

Intake Pump → Feed Tank → Feed Pump → (Dosing: Sodium Hypochlorite for disinfection) → Sand Filter (filters particles; can be omitted if feed water turbidity <0.3 NTU) → (Dosing: Sodium Bisulfite and Antiscalant for residual chlorine removal and scale prevention) → Security Filter → High-Pressure Pump → RO Unit (fresh water permeates the membrane; concentrated brine is discharged after pressure reduction) → Product Water Tank

Rapid Deployment: 40-foot container-integrated design, with over 80% of installation completed before delivery. On-site installation time is only 30% of that of traditional systems, significantly shortening the project cycle.

Strong Corrosion Resistance: High-pressure pipes and fittings are made of Sch10 SS316 stainless steel; the frame and container are coated with heavy-duty marine anti-corrosion paint; wet-contact components are made of duplex steel, SS904L, or UPVC, withstanding long-term erosion by brackish water.

Three-Stage Filtration Protection: The "Sand Filtration → Security Filtration → Main Filtration" three-stage process effectively removes impurities, protecting the high-pressure pump and RO membrane and reducing operation and maintenance costs.

Low-Energy Operation: Equipped with high-efficiency high-pressure pump, IE3 energy-saving motor, and low-energy membrane, with energy consumption per unit product water of only 1.04 kWh/m³, significantly more energy-efficient than traditional systems.

Towns and small cities: Supplement water supply gaps in brackish water areas;

Mining/agriculture: Provide drinking water for mining staff and qualified water for agricultural irrigation in arid areas;

Hotels/resorts: Meet concentrated water demand in tourism scenarios;

Industrial auxiliary: Provide low-salinity water for cooling circulating water and process water.

| System Model | System Code | Filter Kit Code | Insulation Kit Code |

|---|

| BWC500-H (Heated) | 204A107 | 244P007 | 254P007 |

| BWC500 (Standard) | 204A007 | 244P007 | 254P007 |

Filter Kit: Contains filter elements for 1 year of use; additional stock is required if feed water is severely polluted;

Insulation Kit: Includes insulation layer and air conditioner, suitable for high/low temperature environments;

Warranty Policy: When operating strictly in accordance with the Operation Manual, a 12-month warranty is provided (starting from the date of successful commissioning), with a maximum period not exceeding 18 months from the date of delivery.

System Process Diagram:

Product Appearance and Internal Images:

Core Component Images:

FENIGAL Science and Technology (Wuxi) Co., Ltd.

Tel: +86 0510 85163211

Mobile: +86 13646187144

Address: Room 511, Building B, 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, China

Official Website: www.fgwater.com

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system