DHP 1.7 Axial Piston Pumps Complete Guide to Parameters (3000rpm/1.7m³/h) Maintenance & Warranty

In medium-low flow and high-pressure fluid transfer scenarios, such as island seawater desalination and industrial wastewater treatment, DHP 1.7 Axial Piston Pumps (high-pressure piston pumps) have always been popular due to their accurate parameters, strong corrosion resistance, and easy maintenance. Below, we will discuss practical information about this pump, covering parameters, maintenance, and warranty—all core content from the manual.

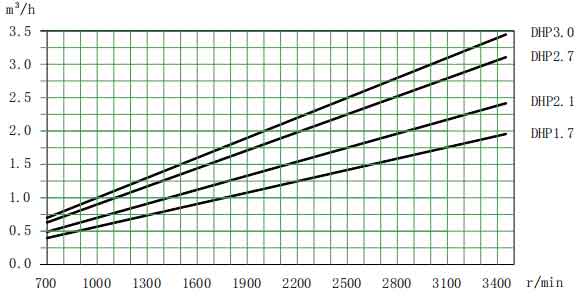

The DHP 1.7's parameters are fully suitable for high-pressure fluid transfer in small and medium-sized projects. Key data are shown in the table below. A "DHP 1.7 Parameter Label Chart - 3.0 Series" is also included below to provide a more intuitive understanding of the relationship between parameters and device structure:

| Parameter Category | Specific Value/Specification | Note (from the manual) |

|---|

| Geometric Displacement | 9.6 cm³/rev | Specified in the manual as the basic displacement of this series, determining the basis for flow calculation |

| Rated Speed | 3000 rpm | Specified in the manual as the normal operating speed; adjustable range is marked next to the diagram |

| Rated Water Output | 1.7 m³/h | Stable output at 3000 rpm, verified by the flow curve in the manual |

| Outlet Pressure Range | Minimum 20 Bar, Maximum Continuous 80 Bar | The manual emphasizes that overpressure triggers the safety valve; the safety valve position is marked in the diagram |

| Inlet Pressure Range | 1-5 Bar | The manual warns that cavitation is likely to occur when pressure is below 1 Bar, requiring monitoring with a pressure gauge |

| Equipment Weight | 7.8 kg | Weight is marked next to the dimension diagram in the manual, suitable for installation in narrow spaces |

| Inlet/Outlet Interface | G3/4〞 (depth 18 mm) | Interface specifications are clearly stated in the interface detail diagram of the manual, enabling direct connection to industrial pipelines |

| Operating Noise | ≤77 dB(A) | Tested and marked in the manual in accordance with EN ISO 3744-2010 standard |

| Core Material | 2205 Duplex Stainless Steel (SAF 2205/EN 1.4462/UNS 31803) | Its corrosion resistance is highlighted in the material description section of the manual |

| Designed Service Life | Over 8000 hours | This parameter is linked in the warranty terms of the manual, serving as the basis for maintenance cycles |

| Special Design | Integrated Flush Check Valve, No Lubricating Oil Tank | The check valve position is marked in the manual's structural diagram, explaining the advantages of the oil-tank-free design |

The figure below shows the flow curve for the DHP 1.7 at 80 bar pressure. It clearly shows that within the speed range of 700-3450 rpm, the flow rate varies linearly with speed, accurately reaching 1.7 m³/h at 3000 rpm, consistent with the datasheet. This also provides a basis for speed adjustment under different operating conditions.

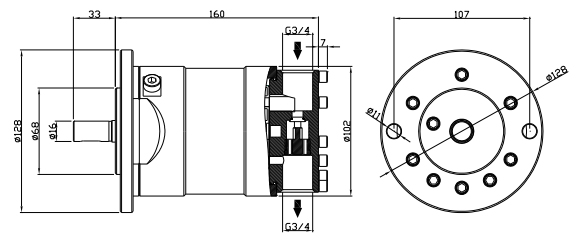

Below are detailed installation dimensions and interface specifications for the 3.0 series (including DHP 1.7). Installation information is as follows:

Interface Size: The dimensional drawing marks the inlet/outlet interface as G3/4" (depth 18mm) and is accompanied by a detailed diagram of the interface line to ensure the pipe matches;

Overall Dimensions: The manual table marks the length × width × height of the equipment corresponding to the adapted motor model (e.g., when matched with a 4.0kW-2P motor, the overall length is 715mm), and the installation reserved space is marked with a dotted line in the diagram;

Coupling Clearance: The installation guide diagram clearly states that the coupling clearance between the motor and pump should be maintained at 3-5mm, with a side note: "Incorrect clearance will damage the shoot-out."

Piston pump model | DHP 0.6~1.0 |

Inlet size | G1/2〞, deep 13 mm |

Outlet size | G1/2〞, deep 13 mm |

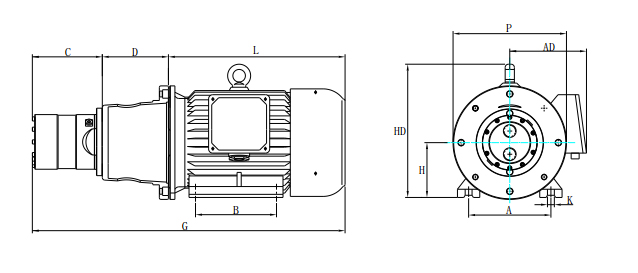

Complete equipment with independent fan motor (frequency conversion motor) Unit: mm

Plunger pump | A | B | H | K | P | AD | HD | C | D | L | G | IEC Motor |

DHP0.6 ~1.0 | 125 | 100 | 80 | 10 | 200 | 145 | 225 | 133 | 100 | 325 | 558 | 1.1kW-2P |

| 140 | 100 | 90 | 10 | 200 | 165 | 255 | 133 | 100 | 340 | 573 | 1.5kW-2P |

| 140 | 125 | 90 | 10 | 200 | 165 | 255 | 133 | 100 | 365 | 598 | 2.2 kW -2P |

| 160 | 140 | 100 | 12 | 250 | 175 | 275 | 133 | 120 | 405 | 658 | 3.0 kW -2P |

The power data of the DHP 1.7 is as follows. We have also attached a "Quick Power Relationship Chart" to facilitate quick motor matching:

| Working Condition | Power | Note from the Manual |

|---|

| 3000rpm, 60Bar Pressure | 4kW | Basic working condition value in the manual's power table |

| 3000rpm, 70Bar Pressure | 5.5kW | Recommended motor power for common working conditions |

| 3000rpm, 80Bar Pressure | 5.5kW | The manual emphasizes this power as the upper limit for continuous operation |

Pump Model | Rated flow | Typical pressure | Rated speed |

| L/ min | m3 / h | 60 Bar | 70 Bar | 80 Bar | rpm |

| DHP1.7 | 26 | 1.7 | 4kW | 5.5kW | 5.5kW | 3000 |

Maintenance can be divided into three parts: routine maintenance, shutdown maintenance, and troubleshooting:

Pressure and Flow Monitoring: The manual requires checking the inlet pressure (≥1 Bar) and outlet pressure (20-80 Bar) with a pressure gauge before starting the pump. If the flowmeter deviation exceeds ±10%, the pipeline should be inspected (the manual diagram marks the installation positions of the pressure gauge/flowmeter);

Filter System Cleaning: The manual mandates that a 10μm absolute precision filter (β10>5000) be installed at the inlet, and the filter element should be disassembled and cleaned weekly. The diagram shows the steps for filter element disassembly;

Interface Seal Inspection: The monthly inspection checklist in the manual clearly states that interface leakage should be checked, and the diagram marks the position for seal ring replacement.

Short-term Shutdown (≤ 3 days)

No additional operation is required; keep the pump filled with the conveyed fluid. Before restarting, it is necessary to bleed all air from the pump and the system to prevent dry friction of the plunger.

Medium-term Shutdown (3-15 days)

If the pump conveys high-salinity fluids (such as seawater, brackish water, or saline wastewater), after shutdown, the pump cavity must be flushed with fresh water for 10-15 minutes to discharge the residual concentrated brine and avoid crystallization that may block the flow channel.

If the pump conveys ordinary fluids (non-high-salinity), the flushing step can be omitted, but the inlet and outlet valves must be closed tightly to prevent external impurities from entering.

Long-term Shutdown (> 15 days)

First, flush the pump body with fresh water containing a bactericide to prevent microbial growth inside the pump.

After flushing, seal the inlet and outlet ports of the pump to isolate it from the external environment.

The storage environment temperature should be controlled within the range of -40℃ to 70℃. When the temperature is below 2℃, antifreeze must be added (the document recommends DuPont Dowcal N or Ackerman Chillsafe Propylene Glycol) to prevent the fluid inside the pump from freezing and damaging the components.

Excessive Noise: First examining the pipe connections, this diagram compares the differences between rigid and flexible connections;

Flow Attenuation: Troubleshooting steps suggest cleaning the filter first, then checking the check valve;

The warranty policy is as follows:

Basic Warranty: Within 1 year from the date of delivery, free maintenance/part replacement is provided for non-human-induced quality issues (the manual lists "human operations" including operation without filtration and overpressure operation);

Extended Warranty: When operating in accordance with the specified working conditions in the manual (80 Bar, 3000 rpm, 10μm filtration), an 8000-hour maintenance-free warranty is provided (maximum 18 months);

After-sales Response: The manual provides the manufacturer's telephone number (+86-510-85163211) and email address ([email protected]), and promises on-site service within 48 hours in China.

Customer Case: An island desalination project used two DHP 1.7 pumps in parallel, with a water output of 30 tons per day, and had no failures after 18 months of operation;

Manufacturer Strength: Fenigal (Wuxi Fenigal Science and Technology Co., Ltd.), has been developing high-pressure piston pumps since 1990 and was the first domestic enterprise to localize axial piston pumps with world-class technology.

To view the complete parameter diagrams, installation details, and warranty terms in the manual, please refer to the manual, or visit the manufacturer's official website (https://www.fgwater.com) and call the customer service hotline [+86-13646187144(Whats App same number)] to obtain the electronic manual.

PDF manual download address:DHP type plunger pump selection manual