DHP 2.1 Axial Piston Pump (High Pressure Pump For Industrial Reverse Osmosis)

This pump is a member of the DHP series of Axial Piston Pumps, specifically designed to transport high-pressure, low-viscosity corrosive fluids such as seawater and industrial saline wastewater. It is particularly suitable for industrial reverse osmosis scenarios including seawater desalination and industrial desalination.

Based on the axial piston pump principle, it operates by the reciprocating motion of plungers parallel to the drive shaft within plunger bores to change volume and convey fluids. Eliminating the need for a traditional lubricating oil tank, it uses the transported fluid itself as a lubricant, completely avoiding oil leakage pollution and thus being highly compatible with the seawater and industrial wastewater we need to treat.

| Parameter Category | Specific Value |

|---|

| Product Model | DHP 2.1 |

| Geometric Displacement | 11.8 cm³/rev |

| Rated Flow at Rated Speed (3000 rpm) | 2.1 m³/h (equivalent to 35 L/min) |

| Outlet Pressure Range | Minimum 20 Bar, Maximum 80 Bar |

| Inlet Pressure Range | Minimum 1 Bar, Maximum 5 Bar |

| Continuous Speed Range | 700~3450 rpm |

| Operating Noise (per EN ISO 3744-2010 Standard) | ≤77 dB(A) |

| Power at 3000 rpm and 80 Bar | 7.5 kW |

| Medium Temperature (depends on NaCl Concentration) | 2~50 ℃ |

| Ambient Temperature | 0~50 ℃ |

| Overall Weight | 7.8 kg |

| Built-in Component | Integrated Flushing Check Valve |

| Core Application | Seawater desalination, industrial wastewater desalination and resource recovery |

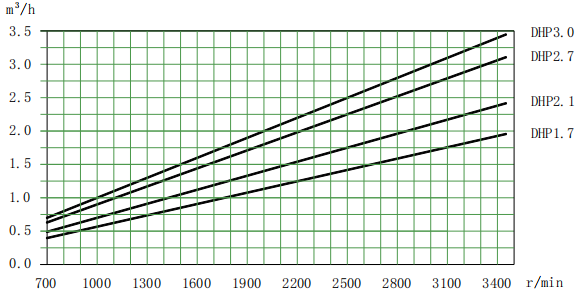

The horizontal axis represents rotational speed (ranging from 700 to 3450 rpm), and the vertical axis represents flow rate (ranging from 0 to 3.5 m³/h). You can directly check the actual flow rate of DHP 2.1 at different rotational speeds. For example, at a rotational speed of 1000 rpm, the flow rate is approximately 0.7 m³/h; at the rated rotational speed of 3000 rpm, the flow rate is exactly the rated 2.1 m³/h.

To calculate the speed for a specific flow rate, use the following formula: Selected motor speed (rpm) = (Desired flow rate × Rated speed 3000) / Rated flow rate 2.1. For example, if we need a flow rate of 1.5 m³/h, the calculated speed is approximately 2140 rpm, which is a very simple calculation.

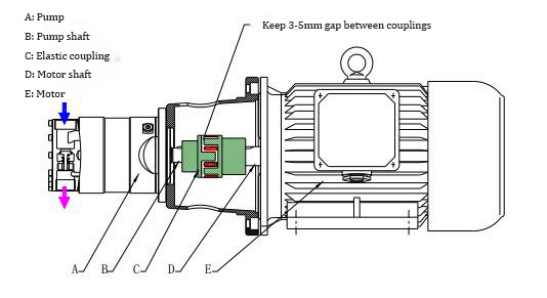

First, identify the interfaces: the port marked "I" on the pump is the inlet, and the one marked "O" is the outlet. Pay attention to this during installation to avoid reverse connection;

Motor connection is crucial: a clearance of 3-5 mm must be reserved between the coupling of the pump and the motor, and the pump shaft must not bear axial or radial force, otherwise it may be easily damaged.

A filter must be installed: Seawater and industrial wastewater definitely contain impurities. A filter with an absolute accuracy of 10 μm (filtration efficiency of 99.98%, β10>5000) must be installed before the pump inlet. Otherwise, small particles will wear out the precision parts inside the pump;

Pressure protection is indispensable: A low-pressure switch should be installed at the inlet, set to 1 Bar, which will shut down the pump when the pressure is lower than this value; a high-pressure switch should be installed between the outlet and the reverse osmosis membrane, set to 70 Bar, which will shut down the pump when the pressure exceeds this value. Additionally, a safety valve must be equipped to prevent system overpressure and pipe burst;

Flushing after shutdown is a priority: When used in high-salinity scenarios such as seawater desalination, the pump cavity must be flushed with fresh water every time the pump is shut down to drain the concentrated brine inside, preventing salt crystallization from blocking the pump; if the shutdown lasts more than 3 days, flushing with fresh water is mandatory; if it lasts more than 15 days, flushing with fresh water containing a bactericide is required; in addition, never start the pump with the rear valve closed, as this may lead to accidents!

The power of DHP 2.1 depends on the actual working pressure. The data are as follows:

| Pump Model | Rated Flow (m³/h) | Power at 60 Bar | Power at 70 Bar | Power at 80 Bar |

|---|

| DHP 2.1 | 2.1 | 5.5 kW | 5.5 kW | 7.5 kW |

Select the motor based on this data. For example, in seawater desalination applications, the working pressure is generally 70-80 Bar, so a 7.5 kW motor is sufficient. There is no need to choose an undersized one, nor to waste money on an oversized one.

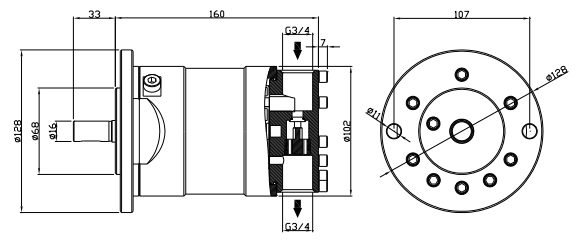

DHP 2.1 has the same dimensions as DHP1.7, 2.7, and 3.0 in the same series. First, let's look at the inlet and outlet dimensions:

| Pump Model | Inlet Size | Outlet Size |

|---|

| DHP 2.1 | G3/4〞, Depth 18 mm | G3/4〞, Depth 18 mm |

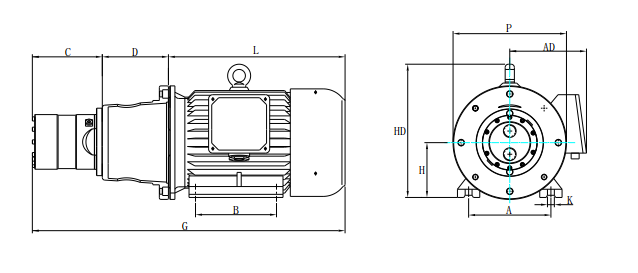

Next, let's look at the overall dimensions (with independent fan motor/inverter motor, unit: mm). The following are examples of sizes that match two common motors:

| Pump Model | A | B | H | K | P | AD | HD | Matching IEC Motor |

|---|

| DHP 2.1 | 216 | 140 | 132 | 12 | 300 | 220 | 350 | 5.5 kW - 2P |

| DHP 2.1 | 216 | 140 | 132 | 12 | 300 | 220 | 350 | 7.5 kW - 2P |

When planning the installation space, follow these dimensions, and there will be no issues.

No need for lubricating oil: This pump is lubricated by the transported fluid, eliminating the trouble of adding lubricating oil, so you don't have to worry about this in daily use;

Regular inspection: If the pump is used as required (equipped with a 10μm filter, pressure and speed are within the specified range), it is recommended to inspect it every 8,000 hours and replace worn parts to avoid repairs after complete damage;

Key point for high-salinity scenarios: In scenarios such as seawater desalination and industrial desalination, the pump cavity must be flushed with fresh water every time the pump is shut down, even for short shutdowns. Otherwise, salt will corrode the pump body (although the pump is made of 2205 duplex stainless steel with good corrosion resistance, it cannot withstand long-term residual high salinity).

Free warranty: From the date of delivery, it comes with a 1-year free maintenance service (excluding damage caused by human factors or improper use);

Extended protection: If the conditions of "specified filtration + normal pressure and speed" are met, it can enjoy an 8000-hour maintenance-free warranty, with a maximum period not exceeding 18 months from the date of delivery;

After-sales support: Whether it is fault detection, on-site repair, factory repair, or spare part replacement, you can contact the manufacturer, and the response is quite timely.

Company: WUXI FENIGAL SCIENCE AND TECHNOLOGY CO., LTD. (FG Water Technologies)

Address: Chuangyi Industrial Park, No. 100 Dicui Road, Binhu District, Wuxi City, Jiangsu Province, P. R. China

Tel: +86-510-85163211

Mobile: +86-13646187144

Email: [email protected]

Official Website: https://www.fgwater.com

The manufacturer of this pump, FENIGAL, has been developing high-pressure piston pumps since 1990 and is the first enterprise in China to engage in axial high-pressure piston pumps. After nearly 15 years of dedicated efforts and innovation, it has brought the technology of this type of pump to the world's advanced level, realized localization, and solved many bottleneck problems restricting the industry.

PDF manual download address:DHP type plunger pump selection manual