LCX Series Industrial EDI Membrane Stacks A Reliable Alternative to IONPURE IP-LXM Series

The EDI module ingeniously combines electrodialysis and ion exchange technologies. It utilizes high voltage from electrodes at both ends to move charged ions in water, and in conjunction with ion exchange resins and selective resin membranes, accelerates the movement and removal of ions. This pure water manufacturing technology integrates ion exchange membrane technology and ion electromigration technology. During the EDI desalination process, ions are removed through ion exchange membranes under the action of an electric field. Meanwhile, water molecules generate hydrogen ions and hydroxide ions under the influence of the electric field, which continuously regenerate the ion exchange resin to keep it in an optimal state.

When accepting EDI modules, enterprises should pay attention to the following aspects:

Quality Compliance: The exterior of the module should be intact and undamaged. Inspectors should check for scratches, dents, and other defects. If problems are found, return or exchange is required.

Order Conformity: Inspectors first check if the physical products match the order. In case of inconsistency, handle return or exchange with the manufacturer's technical personnel. Some manufacturers may cut corners by replacing important materials with cheaper ones.

Random Inspections: To avoid troubles caused by poor-quality raw materials in later use, enterprises should organize quality control personnel to conduct random inspections on EDI modules.

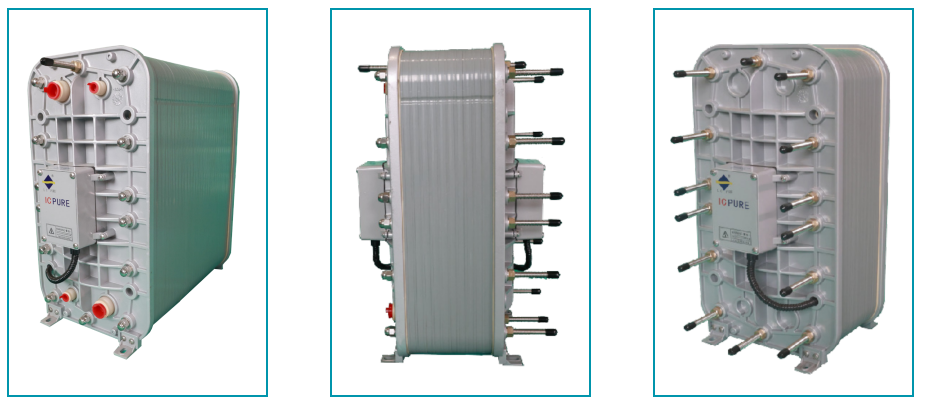

The industrial EDI membrane stack - LCX series, with efficient water purification and stable operation, is widely used in medicine, electronics, semiconductors, photics, power, chemical industry, and vehicle urea purification. Importantly, it can replace IONPURE IP-LXM series, providing a convenient and cost-effective solution for enterprises upgrading or maintaining water treatment equipment. The specific replacement relationships are as follows:

LCX-05T replaces IP-LXM04Z-5

LCX-10T replaces IP-LXM10Z-5

LCX-20T replaces IP-LXM18Z-5

LCX-30T replaces IP-LXM18Z-5

LCX-38T replaces IP-LXM24Z-5

LCX-45T replaces IP-LXM30Z-5

LCX-50T replaces IP-LXM45Z-5

LCX-55T replaces IP-LXM45Z-5

| Replacement Relationship | Model | Flow Range (m³/h) | Operating Current (A) | Operating Voltage (VDC) | Maximum Power (KW/H) |

|---|

| LCX-05T ↔ IP-LXM04Z-5 | LCX-05T | 0.4-0.6 | 2.5 | 0-200 | 1.2 |

| IP-LXM04Z-5 | 0.44-0.67 | 1.0-6.0 | 0-400 | - |

| LCX-10T ↔ IP-LXM10Z-5 | LCX-10T | 0.8-1.2 | 2.5 | 0-200 | 1.2 |

| IP-LXM10Z-5 | 1.1-1.65 | 1.0-6.0 | 0-400 | - |

| LCX-20T ↔ IP-LXM18Z-5 | LCX-20T | 1.8-2.3 | 2.5 | 0-340 | 2 |

| IP-LXM18Z-5 | 2.0-3.1 | 1.0-6.0 | 0-400 | - |

| LCX-30T ↔ IP-LXM18Z-5 | LCX-30T | 2.8-3.2 | 2.5 | 0-340 | 2 |

| IP-LXM18Z-5 | 2.0-3.1 | 1.0-6.0 | 0-400 | - |

| Replacement Relationship | Model | Flow Range (m³/h) | Operating Current (A) | Operating Voltage (VDC) | Maximum Power (KW/H) |

|---|

| LCX-38T ↔ IP-LXM24Z-5 | LCX-38T | 3.8-4.2 | 2.5 | 0-550 | 3 |

| IP-LXM24Z-5 | 2.8-4.2 | 1.0-6.0 | 0-400 | - |

| LCX-45T ↔ IP-LXM30Z-5 | LCX-45T | 4.8-5.3 | 2.5 | 0-550 | 3 |

| IP-LXM30Z-5 | 3.3-5.11 | 1.0-6.0 | 0-400 | - |

| LCX-50T ↔ IP-LXM45Z-5 | LCX-50T | 5.8-6.3 | 2.5 | 0-550 | 3 |

| IP-LXM45Z-5 | 5.1-7.67 | 1.0-6.0 | 0-400 | - |

| LCX-55T ↔ IP-LXM45Z-5 | LCX-55T | 6.8-7.3 | 2.5 | 0-550 | 3 |

| IP-LXM45Z-5 | 5.1-7.67 | 1.0-6.0 | 0-400 | - |

| Replacement Relationship | Model | Dimensions (mm) | Shipping Weight (KG) | Positioning Hole Spacing (mm) |

|---|

|

| Height × Width × Total Length A |

| Left-Right × Front-Back |

| LCX-05T ↔ IP-LXM04Z-5 | LCX-05T | 605×315×270 | 40 | 215×160 |

| IP-LXM04Z-5 | Length 257 × Width 146.8 (Height unmarked) | 59 | - |

| LCX-10T ↔ IP-LXM10Z-5 | LCX-10T | 605×315×370 | 50 | 215×235 |

| IP-LXM10Z-5 | Length 347.7 × Width 235.7 (Height unmarked) | 78 | - |

| LCX-20T ↔ IP-LXM18Z-5 | LCX-20T | 605×315×560 | 75 | 215×385 |

| IP-LXM18Z-5 | Length 488.2 × Width 353.8 (Height unmarked) | 99 | - |

| LCX-30T ↔ IP-LXM18Z-5 | LCX-30T | 605×315×735 | 100 | 215×545 |

| IP-LXM18Z-5 | Length 488.2 × Width 353.8 (Height unmarked) | 99 | - |

| Model | Fresh Water Inlet/Outlet (Male Thread) | Concentrated Water Inlet/Outlet (Male Thread) |

|---|

| LCX-05T | 1-1/4″ PT | 3/4″ PT |

| LCX-10T | 1-1/4″ PT | 3/4″ PT |

| LCX-20T | 1-1/4″ PT | 3/4″ PT |

| LCX-30T | 1-1/4″ PT | 3/4″ PT |

| LCX-38T | 1-1/4″ PT | 3/4″ PT |

| LCX-45T | 1-1/4″ PT | 3/4″ PT |

| LCX-50T | 1-1/4″ PT | 3/4″ PT |

| LCX-55T | 1-1/4″ PT | 3/4″ PT |

| Parameter Category | General Requirements for LCX Series | General Requirements for IP-LXM Series |

|---|

| Product Water Resistivity | ≥15MΩ·CM | Minimum Flow > 17MW-cm; Maximum Flow > 7MW-cm |

| Feed Water Source | RO Permeate | RO Permeate |

| Feed Water Conductivity (including CO₂ and Silica) | <10μs/cm (Recommended <5μs/cm) | <40μs/cm |

| Temperature Range | 5-30℃ | 5-45℃ |

| Inlet Pressure | 0.1-0.3MPa | 1.4-6.9bar (20-100psig) |

| Maximum Total Chlorine (as Cl₂) | <0.02ppm | <0.05ppm |

| Iron (Fe), Manganese (Mn) | Both <0.01ppm | Both <0.01ppm |

A mid-sized electronics factory was using IONPURE IP-LXM18Z-5 in its circuit board cleaning process. However, it faced frequent breakdowns and unstable water quality, which affected product quality. After switching to LCX-20T (which replaces IP-LXM18Z-5), significant improvements were observed:

From the parameter perspective, the flow range of LCX-20T is 1.8-2.3 m³/h, which is slightly lower than that of IP-LXM18Z-5 (2.0-3.1 m³/h), but it can fully meet the factory's actual water demand. The operating current of LCX-20T is fixed at 2.5A, while IP-LXM18Z-5 has a variable range of 1.0-6.0A, making LCX-20T more stable in operation.

In terms of product water quality, the resistivity of LCX-20T stabilized at 17 MΩ·cm, which is better than the maximum flow state of IP-LXM18Z-5 (>7MW-cm). This reduced circuit board corrosion by 35% and improved the product qualification rate by 12%.

In terms of operational efficiency, the stable operation of LCX-20T reduced unplanned production stops from 5 times a month to once, significantly enhancing production efficiency.

In terms of cost, due to the reliable quality and easy replacement of the LCX series, maintenance costs decreased by 40% annually compared to using IP-LXM18Z-5.

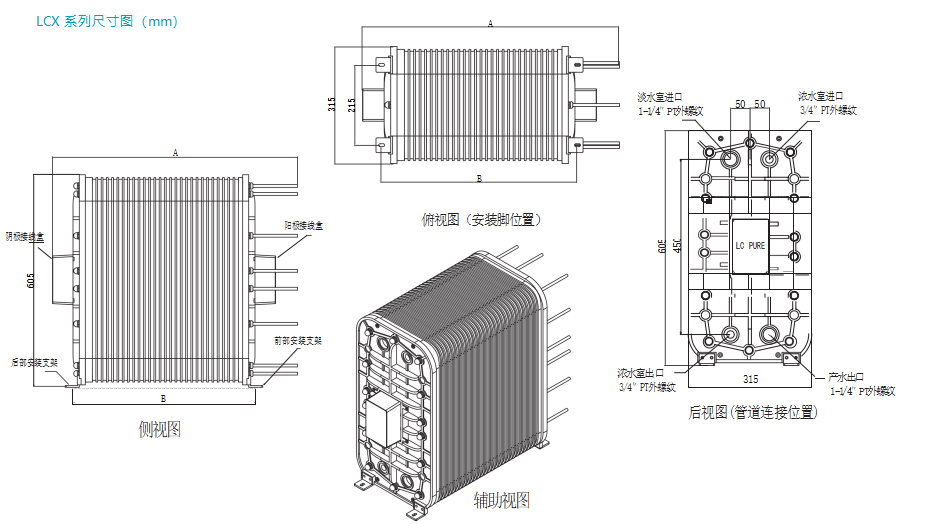

LCX series dimension diagram (mm)