BWC2000-H Containerized Brackish Water Reverse Osmosis System

In extra-large water-consuming scenarios (such as super-large towns and large industrial parks) where brackish water resources are abundant but fresh water resources are extremely scarce, desalination equipment with ultra-large capacity and high stability is crucial for ensuring water supply security. The FENIGAL BWC2000-H Containerized Brackish Water Reverse Osmosis System, with a dual-container configuration of "40ft + 40ft" as its integrated carrier, integrates a full set of high-performance desalination components and intelligent control modules. Relying on its daily 2,000-ton-level water production capacity and low energy consumption advantages, it provides a professional solution for ultra-large-scale brackish water desalination needs.

As the flagship containerized model for top-scale brackish water desalination in the Desal BWC series, the BWC2000-H adopts a dual-container modular design: the pretreatment system, two-stage reverse osmosis unit, chemical cleaning and dosing system, and electrical control unit are respectively deployed in two 40ft standardized containers. No additional workshops need to be built, significantly reducing on-site construction work and land occupation costs. Designed based on the working condition of "4,000 ppm, 20°C brackish water", its rated daily fresh water output reaches 2,040 cubic meters (calculated based on a rated water production flow rate of 85 m³/h and 24-hour daily operation). This capacity can meet the daily drinking water needs of approximately 10,000 people, or support 20,000-acre agricultural irrigation and circulating water demand for large-scale power/chemical enterprises.

Rapid Commissioning and Integration: Over 95% of component installation and pipeline connection are completed in the factory. On-site operations only require connecting water inlet, power supply, and drainage interfaces, shortening the commissioning cycle to less than 20 days, which is much faster than traditional decentralized systems.

Strong Corrosion Resistance: High-pressure pipelines and fittings are made of Sch10 SS316 stainless steel; the container frame and inner wall are coated with heavy-duty marine anti-corrosion paint; wet-area components are made of corrosion-resistant materials such as duplex steel and SS904L, with a designed service life of more than 15 years.

Low-Energy Operation: Equipped with a high-efficiency high-pressure pump, IE3-class energy-saving motor, and low-energy reverse osmosis membrane, the energy consumption per unit water production is only 1.05 kWh/m³, which is 25% lower than the average energy consumption of similar equipment in the industry.

Four-Level Filtration Protection: Adopting a "coarse filtration + sand filter + pre-filter + main filter" process, it traps impurities with a particle size ≥ 1μm in brackish water, avoiding wear of the high-pressure pump and membrane pollution. The service life of membrane modules can be extended to 3-5 years.

Intelligent Operation & Maintenance and Rapid Recovery: Equipped with a Siemens PLC control system, it supports real-time monitoring of key parameters; core components are standardized universal models. In case of failure, the system can be quickly restored by replacing parts, reducing downtime to less than 4 hours.

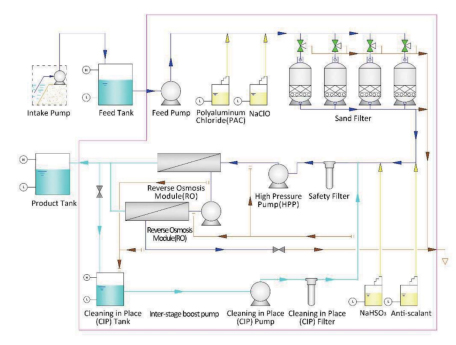

BWC2000-H adopts the core technology of "deep pretreatment + two-stage reverse osmosis" to achieve efficient desalination of brackish water through a closed-loop process. The specific steps are as follows:

Water Intake and Storage: A high-power intake pump extracts brackish water and sends it to a feed tank with a volume of ≥ 100 m³ for temporary storage. The water tank balances flow and pressure through a liquid level sensor and frequency conversion device to avoid the impact of inlet water fluctuations on the system.

In-Depth Pretreatment:

The feed pump pressurizes the water to 4-6 barg, and simultaneously doses Poly Aluminium Chloride (PAC) to flocculate impurities and Sodium Hypochlorite (NaClO) for sterilization (residual chlorine controlled at 0.5-1.0 mg/L).

The water flows through 10 parallel sand filters (Φ1600mm) to filter impurities with a particle size > 5 μm (the sand filter can be bypassed if turbidity < 0.3 NTU).

Sodium Bisulfite (NaHSO₃) is dosed to remove residual chlorine (residual chlorine < 0.1 mg/L), and an anti-scalant is dosed to inhibit scaling. Finally, the water passes through a 5μm safety filter to trap tiny impurities.

Two-Stage Reverse Osmosis Desalination: A high-pressure pump with three parallel pumps (total power 89.4 kW) pressurizes the water to 20 barg. The water first undergoes preliminary desalination through the first-stage RO membrane (60 pieces of 8040-type membranes), then deep desalination through the second-stage RO membrane (48 pieces of 8040-type membranes), and the product water TDS is reduced to below 500 mg/L. The concentrated water is discharged after pressure relief and can be recycled for slag flushing, dust suppression, etc.

Product Water and Membrane Maintenance: Fresh water is stored in a product tank with a volume of ≥ 200 m³ and transported to water points as needed; the system is equipped with two sets of CIP (Cleaning in Place) devices (2 1000L water tanks + dual pumps) to regularly clean membrane modules to maintain efficiency.

The following parameters are designed based on "4,000 ppm, 20°C brackish water":

| Technical Parameter | Unit | BWC2000-H Configuration | Remarks |

|---|

| Rated Product Flow | m³/h | 85 | Corresponding to a daily output of 2,040 m³; output can be increased by 10%-15% when TDS < 3,000 ppm |

| Rated Product Flow | L/S | 23.61 | - |

| Rated Recovery Rate | % | 70 | 70% of the inlet water is converted into fresh water, and 30% is concentrated water (TDS ≈ 13,000 ppm), which can be customized and adjusted |

| Rated Feed Flow | m³/h | 121.43 | Designed to match the two-stage RO membrane, ensuring a membrane surface velocity of 1.2-1.5 m/s |

| Maximum System Pressure | barg | 20 | Normal operating pressure is 18-20 barg; a 25 barg version can be customized for high-TDS (> 6,000 ppm) scenarios |

| RO Membrane Specification | inch | 8040 | Industry universal model, compatible with brands such as Dow and Hydranautics |

| Quantity of RO Membranes | pcs | 108 | 60 pieces for the first stage (parallel-series connection), 48 pieces for the second stage (series connection), with a desalination rate ≥ 98% |

| Dry Weight of Equipment | ton | 26+6 | The total dry weight of the dual containers is 32 tons (excluding operating water), suitable for 40ft container transportation |

| Container Size | ft | 40+40 | Single container: length 12.19m × width 2.44m × height 2.59m, transportable separately |

| Rated Power (Core Equipment) | kW | 89.4 | Includes power of three high-pressure pumps, two CIP pumps, and dosing pumps; excludes intake pump (additional configuration required, power ≥ 25 kW) |

| Energy Consumption per Unit Product Water | kWh/m³ | 1.05 | Ultra-low energy consumption, saving more than 25% energy compared with traditional equipment |

| Installed Power (Including Auxiliary Equipment) | kW | 138.7 | Includes power of core equipment + lighting + control cabinet; requires a three-phase power supply line of ≥ 150 kW |

| Power Input | - | 3PH, 380VAC±10%, 50Hz | Versions with 220V/480V voltage and 60Hz frequency can be customized |

Note: Rated parameters are designed based on standard brackish water. If the inlet water quality varies significantly, please contact the manufacturer for adjustments; rated power does not include the power of the intake pump, product water transfer pump, and air conditioner.

BWC2000-H has clear restrictions on the inlet water quality, and the outlet water meets the WHO drinking water standards. The specific parameters are as follows:

| Category | Indicator | Requirement | Remarks |

|---|

| Feed Water Standards | Salinity (TDS) | 1,000-5,000 mg/L | Nanofiltration pretreatment is required if TDS > 5,000 mg/L |

| Temperature | 5-35°C | Heating is required if temperature < 5°C, and cooling is required if temperature > 35°C to avoid affecting membrane efficiency |

| Turbidity | <40 NTU | A sedimentation tank + multi-media filtration is required if turbidity > 40 NTU |

| Chemical Oxygen Demand (COD) | <10 mg/L | Activated carbon filtration is required if COD > 10 mg/L |

| Ferrous (Fe²⁺) | <0.1 mg/L | If exceeding the standard, KMnO₄ needs to be dosed for oxidation before filtration |

| Manganese (Mn²⁺) | <0.1 mg/L | Manganese sand filtration needs to be added if exceeding the standard |

| Oil and Grease | 0 mg/L | An oil separator must be installed to prevent membrane damage |

| Product Water Standards (Drinking Water) | Salinity (TDS) | <500 mg/L | Meets WHO "Guidelines for Drinking Water Quality" (4th edition, 2012) |

| pH Value | 6-8 | No adjustment needed, suitable for human consumption |

| Turbidity | <0.2 NTU | Clear water quality with no visible impurities |

Note: Special pretreatment must be added if the inlet water contains heavy metals; EDI devices can be added to improve purity for industrial product water as needed.

The BWC2000-H is suitable for various ultra-large brackish water desalination scenarios. Specific parameters are as follows:

Super-Large Towns/Satellite Cities: Replace cross-regional fresh water transfer to meet the large-scale drinking water needs of remote towns.

Ten-Thousand-Acre-Level Agricultural Bases: Treat underground brackish water to provide irrigation fresh water for crops and improve yield.

Large Industrial Parks: Supply production water for the power and chemical industries, or treat circulating water discharge for reuse.

Super-Large Mining Areas/Energy Bases: Ensure stable water supply for employee living areas and power plant cooling systems.

Large Resorts/Golf Courses: Meet the ultra-large green irrigation and domestic water needs of tourists.

The following is the purchasing information:

| Item | Specific Content | Description |

|---|

| System Model | BWC2000-H | Containerized brackish water reverse osmosis system, "40ft + 40ft" dual-container specification |

| System Code Number | 204A111 | Internal identifier of the manufacturer, used for order confirmation and after-sales tracking |

| Filter Kit Code Number | 244P011 | Includes filter elements (sand filter media, safety filter elements, etc.) for 1 year of use; additional procurement is required if the inlet water contains many impurities |

| Insulation Kit Code Number | 254P007 | Includes insulation layers (50mm flame-retardant polyurethane) + industrial air conditioners for two containers, suitable for environments of -15℃-45℃ |

Note: The filter kit dosage is based on normal water quality; additional spare filter elements need to be purchased if the turbidity is high.

If operated in accordance with the Operation Manual, the manufacturer provides a triple warranty:

Core Equipment Warranty: 24-month warranty for high-pressure pumps, reverse osmosis membranes, control cabinets, etc. (starting from the date of qualified commissioning);

Overall System Warranty: 12-month warranty for the entire system except for vulnerable parts (filter elements, O-rings) (starting from the date of qualified commissioning);

Maximum Warranty Period: No more than 18 months from the date of factory shipment (whichever expires first);

Service Response: Response within 48 hours and repair/replacement within 72 hours during the warranty period (except for remote areas).

For inquiries about technical details or procurement, please contact us through the following methods:

Landline: +86 0510 85163211

Mobile Phone: +86 13646187144

Address: Room 511, Block B, 100 Dicui Road, Binhu, Wuxi, Jiangsu, China

Official Website: www.fgwater.com

Email: [email protected]

For more products, please visit: https://www.fgwater.com/Containerized-Water-Purification-System/

PDF manual download address:Desal BWC series Containerized BWRO system